Cnc Machine Company Name List In India

Top sponsor listing

Top sponsor listing

About cnc machine company name list in india

Where to Find CNC Machine Suppliers in India?

India's CNC machine manufacturing sector is increasingly supported by a network of export-oriented suppliers, many of which are based in industrial hubs across Shandong and other key provinces in China. While domestic Indian production is growing, a significant portion of competitively priced, high-volume CNC equipment originates from Chinese manufacturers serving the Indian market. These suppliers benefit from vertically integrated production ecosystems—spanning casting, precision machining, control system integration, and final assembly—enabling cost efficiencies and scalable output.

Clusters in Shandong province, particularly around Jinan and Zaozhuang, host multiple CNC-focused manufacturers with dedicated export channels to South Asia. These regions offer logistical advantages via Qingdao Port, reducing shipping time and freight costs for Indian importers. Integrated supply chains allow for 15–25% lower unit pricing compared to fully localized Indian production, especially for mid-range CNC lathes, vertical machining centers, and wood routers. Lead times for standard models typically range from 30 to 45 days, with customization adding 7–14 days depending on complexity.

How to Choose CNC Machine Suppliers for the Indian Market?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify compatibility with Indian power standards (415V, 3-phase) and environmental conditions. Prioritize suppliers offering CE or ISO 9001 certification as baseline indicators of quality management. For industrial-grade applications, confirm spindle motor specifications, axis positioning accuracy (±0.01mm typical), and controller options (Fanuc, Siemens, GSK). Machines should include thermal stabilization systems, automatic tool changers, and safety interlocks such as security doors and emergency shutdowns.

Production and Customization Capability

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 5,000m² for sustained production capacity

- In-house CNC machining and assembly lines to ensure component traceability

- Customization support for controller configuration, rotary tables, chip conveyors, and oil separators

- Availability of optical rulers, absolute sensors, and rollerless gear systems for high-precision tasks

Cross-reference product listings with reorder rates and response times—suppliers maintaining ≤2-hour response windows and >25% reorder rates demonstrate consistent service delivery.

Transaction Security and After-Sales Support

Utilize secure payment mechanisms that release funds post-delivery verification. Evaluate online revenue trends and order fulfillment history as proxies for business stability. Confirm availability of technical documentation, operator panels in English, and remote diagnostics support. Pre-shipment inspections and sample testing are recommended to validate build quality and performance under simulated operating conditions.

What Are the Leading CNC Machine Suppliers for India?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Key Features |

|---|---|---|---|---|---|---|

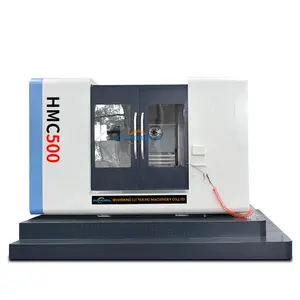

| Shandong Lu Young Machinery Co., Ltd. | CNC Lathe (732), Machining Centre (291), CNC Milling Machines (164) | 100% | ≤2h | 40% | US $110,000+ | Rotary table, controller system options, automatic shutdown, tool changer, thermal stabilization |

| Shandong Alles Energy Technology Co., Ltd. | CNC Lathe (669), Machining Centre (350), Drilling Machines (99) | 100% | ≤6h | 100% | US $6,000+ | Semi-automatic VMC, double-axis design, particle conveyor, spindle motor integration |

| Shandong Mainland Cnc Equipment Co., Ltd. | CNC Lathe (497), Machining Centre (214), Manual Mills (326) | 100% | ≤3h | 25% | US $180,000+ | Fanuc/Siemens/GSK controls, VMC1060/1270 models, 3-axis vertical machining centers |

| Jinan Renxi Technology Co., Ltd. | Wood Routers (89), Laser Cutters (5) | 100% | ≤2h | <15% | US $30,000+ | 4-axis CNC routers, 4x8 ft working area, mass-production ready designs |

| BHAVYA MACHINE TOOLS LLP | CNC Lathe (147), Drilling Machines (51) | - | ≤4h | - | - | Heavy-duty slant-bed and flat-bed lathes, precision engineering focus |

Performance Analysis

Shandong-based suppliers dominate in both volume and reliability, with 100% on-time delivery records across multiple firms. Shandong Lu Young and Shandong Mainland exhibit strong export performance, supported by diversified product portfolios and high online transaction volumes. Notably, Shandong Alles Energy Technology achieves a 100% reorder rate, indicating exceptional customer satisfaction despite lower reported revenue—suggesting niche specialization or direct sales channels. Jinan Renxi focuses on woodworking automation, offering entry-level 4-axis routers ideal for small workshops. BHAVYA MACHINE TOOLS LLP represents an India-facing entity with localized branding, though verifiable performance metrics are limited.

FAQs

What certifications should CNC machine suppliers have?

ISO 9001 is essential for quality management. CE marking ensures compliance with European safety standards, often required for customs clearance. Additional validation includes test reports for spindle runout, axis repeatability, and electrical system integrity.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 unit, facilitating pilot procurement. Standard lead time ranges from 30–45 days after deposit confirmation. Custom configurations may extend this by 10–15 days, particularly if specialized controllers or structural modifications are requested.

Can suppliers customize CNC machines for Indian factories?

Yes, leading suppliers offer configurable options including control systems (GSK common for cost-sensitive buyers), voltage adaptation, dust extraction integration, and user interface localization. Some provide optional air conditioning units for operator panels in high-temperature environments.

Do suppliers provide installation and training?

While not standard, many offer remote setup guidance via video or manuals. On-site commissioning and training can be negotiated at additional cost. Buyers are advised to request pre-shipment run tests with video evidence of machine operation.

How are CNC machines packaged and shipped?

Machines are typically crated in seaworthy wooden enclosures with anti-vibration padding. FOB terms are common, but CIF can be arranged. Full container loads (20ft or 40ft) are optimal for multi-unit orders. Air freight is viable only for compact models due to weight and dimensional constraints.