Cnc Machine Controller List

Top sponsor listing

Top sponsor listing

About cnc machine controller list

Where to Find CNC Machine Controller Suppliers?

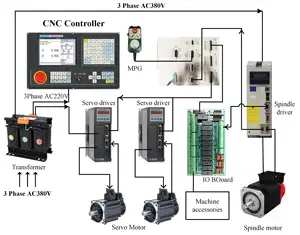

China remains the central hub for CNC machine controller manufacturing, with key production clusters in Shandong, Sichuan, and Guangdong provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production of control systems for milling machines, lathes, routers, and multi-axis automation platforms. Shandong’s Jinan cluster specializes in woodworking CNC controllers, leveraging proximity to MDF and metal fabrication centers to streamline component sourcing. Chengdu-based suppliers focus on servo-driven and PLC-integrated solutions tailored for industrial lathe and milling applications.

The ecosystem benefits from mature electronics manufacturing infrastructure, enabling tight integration between motion control hardware, driver software (e.g., NC Studio, DSP), and human-machine interfaces. Suppliers typically operate compact but highly specialized facilities optimized for electronic assembly rather than heavy machining, allowing lead times as short as 7–15 days for standard units. Buyers gain access to a diverse range of configurations—including 3-axis, 4-axis, and 5-axis support—with pricing influenced by processor type, I/O capacity, and compatibility with spindle types (air-cooled, water-cooled, ATC-equipped).

How to Choose CNC Machine Controller Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

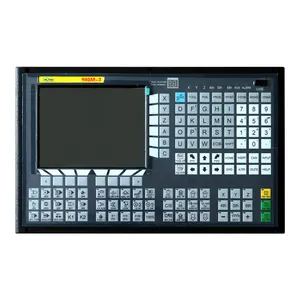

Confirm compatibility with target machinery types (router, plasma cutter, laser, or lathe) and control standards (G-code, M-code). Prioritize suppliers offering documented support for industry-standard software environments such as RichAuto, GSK, WeiHong, and DSP-based systems. For high-precision applications, verify closed-loop feedback integration with servo motors and encoder systems.

Production & Customization Assessment

Evaluate supplier scope through these benchmarks:

- Proven ability to customize control logic, I/O mapping, and HMI layouts

- Support for multiple motor types: stepper, servo, hybrid configurations

- Availability of auxiliary integrations: vacuum tables, tool changers (ATC), oscillating knives, rotary axes

- Cross-reference product listings with reorder rates (>20% indicates customer retention) and response times (≤2 hours preferred)

Transaction Reliability Indicators

Favor suppliers demonstrating consistent on-time delivery performance (target ≥97%) and verifiable post-sale support. Analyze listed product pricing consistency and minimum order terms—most suppliers offer MOQs of 1 piece, facilitating sample testing. Where available, assess component-level transparency, including use of branded drivers, power supplies, and EMI shielding practices.

What Are the Best CNC Machine Controller Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Response Time | Customization Support | Price Range (USD) | Notable Features |

|---|---|---|---|---|---|---|---|---|

| Jinan Mingshi Machinery Equipment Co., Ltd. | Wood Routers (1,125) | US $300,000+ | 100% | 21% | ≤1h | Yes | N/A | Broad system integration; supports NC Studio, CO2 lasers, ATC, vacuum tables |

| Chengdu Newker CNC-Technology Co., Ltd. | CNC Controllers, Servo Systems | US $290,000+ | 97% | 42% | ≤2h | Yes | $280–$480 | PLC + servo integration; 5-axis capable; lathe/milling focused |

| Jinan Yinfan Electromechanical Equipment Co., Ltd. | CNC Controller (26), Spindles | US $10,000+ | 100% | <15% | ≤1h | Limited | $150–$466 | DSP-0501, RichAuto A11, WeiHong systems; cost-effective entry-tier |

| Foshan Microcontrol Industrial Automation Technology Co., Ltd. | 5-Axis, Remote Controllers | US $600+ | 100% | - | ≤2h | Yes | $299–$580 | Unique remote interface design; low-cost 4-axis option |

| Fancy Machinery Co., Ltd. | CNC Controller (122), GSK Systems | US $10,000+ | 66% | 16% | ≤1h | Yes | $610–$2,150 | Original GSK980TDc, GSK218MC-H; premium OEM-grade systems |

Performance Analysis

Chengdu Newker stands out with a 42% reorder rate, indicating strong customer satisfaction in servo-integrated controller segments. Jinan Mingshi leads in ecosystem breadth, supporting complex workflows involving material handling, dust collection, and multi-tool changers. Fancy Machinery offers high-end GSK-branded controllers but raises concerns due to a low 66% on-time delivery rate, suggesting potential fulfillment bottlenecks despite technical capability. Budget-conscious buyers may consider Jinan Yinfan’s sub-$150 DSP units, though limited customization and lower reorder volume signal niche positioning. Foshan Microcontrol shows innovation in remote operation design but lacks transaction volume indicators for scalability assessment.

FAQs

What certifications should CNC controller suppliers have?

While not universally enforced, ISO 9001 process compliance is recommended for quality assurance. CE marking is critical for European market access, confirming electromagnetic compatibility (EMC) and safety under relevant EU directives. Suppliers should provide documentation for surge protection, grounding integrity, and operating temperature validation.

What is the typical lead time for CNC controllers?

Standard units ship within 7–15 days after order confirmation. Custom firmware programming or hardware modifications may extend timelines to 25–30 days. Air freight adds 5–10 days globally; sea freight remains viable only for bulk orders (≥50 units).

Do suppliers support global shipping and voltage adaptation?

Yes, most suppliers configure power input ranges (AC 110V–220V ±10%) to suit regional grids. They also provide English-language software interfaces and technical documentation. Confirm inclusion of step-down transformers if required and verify export packaging standards (anti-static, shock-resistant).

Are free samples available for testing?

Sample policies vary. Some suppliers offer paid samples refundable against future orders. Units priced below $200 are rarely offered gratis due to thin margins. Expect to cover express shipping (DHL/FedEx) unless otherwise negotiated.

How to validate controller compatibility before purchase?

Provide detailed specifications: machine type, motor type (stepper/servo), number of axes, spindle power, and desired software environment. Request demonstration videos showing boot-up sequences, parameter settings, and simulated operation. Reputable suppliers will supply configuration guides or compatibility checklists upon inquiry.