Cnc Machined Part Supplier

Top sponsor listing

Top sponsor listing

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

CN

CN

1/18

1/18

1/3

1/3

0

0

1/23

1/23

1/17

1/17

0

0

0

0

0

0

1/17

1/17

1/3

1/3

1/21

1/21

1/3

1/3

1/21

1/21

1/3

1/3

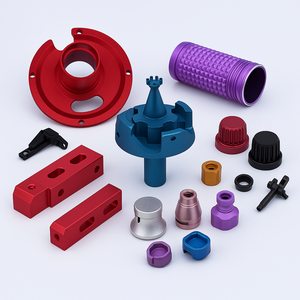

About cnc machined part supplier

Where to Find CNC Machined Part Suppliers?

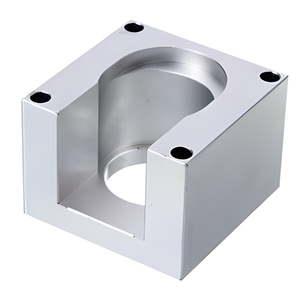

China remains the global epicenter for precision CNC machining, with supplier clusters in Guangdong, Shandong, and Qingdao offering robust manufacturing ecosystems. The Pearl River Delta, particularly Shenzhen, hosts a dense network of custom manufacturers specializing in high-mix, low-to-medium volume production. These regions benefit from mature supply chains for raw materials—such as aluminum 6061/7075, stainless steel 303/316, brass C3604, and engineering plastics—enabling rapid prototyping and scalable batch production.

Industrial zones in these areas feature vertically integrated facilities combining CNC turning, milling (3-axis, 4-axis, 5-axis), EDM, grinding, and post-processing services like anodizing, sandblasting, and polishing. This integration reduces component lead times by up to 40% compared to fragmented outsourcing models. Buyers gain access to agile suppliers capable of fulfilling orders ranging from one-off prototypes to volumes exceeding 10,000 units monthly, supported by localized logistics and export-ready compliance frameworks.

How to Choose CNC Machined Part Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

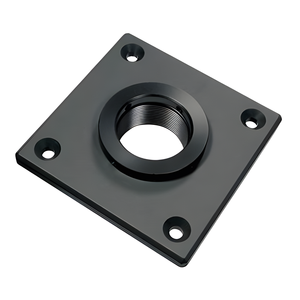

Technical Capabilities & Compliance

Verify that suppliers support required tolerances (typically ±0.005mm to ±0.01mm) and possess multi-axis CNC equipment for complex geometries. ISO 9001 certification should be considered a baseline for quality management systems. For regulated industries (medical, aerospace, automotive), confirm adherence to AS9100, IATF 16949, or equivalent standards. Review available material certifications and process validation documentation, especially for critical applications.

Production Capacity and Flexibility

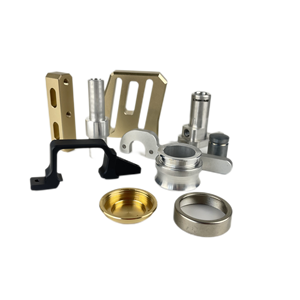

Assess core competencies through service offerings:

- In-house capabilities in CNC turning, milling, wire EDM, and sheet metal fabrication

- Support for secondary operations: heat treatment, plating, laser engraving, thread insertion

- Design-for-manufacturability (DFM) feedback and drawing validation processes

Prioritize suppliers with documented on-time delivery rates above 94% and response times under 2 hours, indicators of operational discipline and customer service infrastructure.

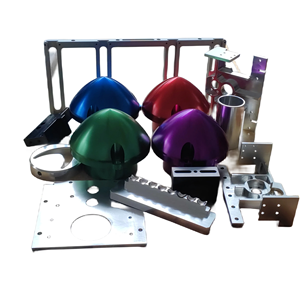

Customization and Transaction Security

Ensure clear protocols for handling custom designs, including IP protection agreements and secure file transfer methods. Confirm minimum order quantity (MOQ) flexibility—many suppliers accept MOQs as low as 1 piece for prototypes. Use milestone-based payment terms with inspection checkpoints. Where applicable, leverage third-party inspection services pre-shipment to validate dimensional accuracy and surface finish against provided CAD models or engineering drawings.

What Are the Best CNC Machined Part Suppliers?

| Company Name | Type | Main Services | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Selection Hardware Technology Co.,Ltd. | Custom Manufacturer | Machining, Casting, Sheet Metal | US $1,900,000+ | 100% | ≤2h | 40% | 5-axis, anodizing, polishing, labeling, sandblasting, material selection | Varies by product |

| 24K Investment (Qingdao) Co., Ltd. | Manufacturer | Machining, EDM, Sheet Metal, Moulds | US $8,000+ | 93% | ≤2h | 16% | High-precision CNC and EDM machining | 50–100 cm / 1 dozen |

| JUNYING METAL MANUFACTURING CO., LIMITED | Manufacturer | CNC Machining Services | Not disclosed | 100% | ≤2h | Not disclosed | Precision turning, milling, plating, alloy gearbox components | 1–10 pieces |

| JINKE VIET NAM INDUSTRIAL CO.,LTD | Manufacturer | Machining, Sheet Metal, Casting, Moulds | US $20,000+ | 94% | ≤1h | Not disclosed | Anodized aluminum, brass parts, mass customization | 1 piece |

| SHIVAY ENTERPRISE | Supplier | Machining, Fasteners, Exhaust Systems | US $7,000+ | 94% | ≤1h | Not disclosed | OEM/ODM, bespoke designs, high-precision builds | 1–10 pieces |

Performance Analysis

ShenZhen Selection Hardware stands out with the highest online revenue and a 40% reorder rate, indicating strong customer retention and scalable operations. Its comprehensive service portfolio—including 5-axis machining and full finishing options—makes it suitable for complex, high-value components. JUNYING METAL and JINKE VIET NAM offer exceptional responsiveness (≤2h and ≤1h, respectively) and accept single-piece MOQs, ideal for prototyping and low-volume trials. While 24K Investment reports lower reorder metrics, its specialization in EDM and high-precision machining may serve niche technical requirements. SHIVAY ENTERPRISE provides broad customization at competitive pricing but operates at a smaller scale. Buyers should align supplier selection with project phase: use agile, low-MOQ vendors for development, and prioritize high-revenue, high-delivery performers for volume production.

FAQs

How to verify CNC machined part supplier reliability?

Validate technical claims through facility videos, machine lists, and sample inspections. Request evidence of quality control processes such as first-article inspection (FAI) reports, CMM measurement data, and material traceability certificates. Analyze historical performance metrics including on-time delivery and response time consistency.

What is the typical lead time for custom CNC parts?

Prototype lead times range from 5–7 days for simple components to 10–14 days for complex, multi-process parts. Batch production typically takes 15–25 days depending on order size and finishing requirements. Expedited services are available from select suppliers at a premium.

Do CNC suppliers support international shipping?

Yes, most established suppliers have export experience and partner with freight forwarders to manage global shipments. Confirm Incoterms (e.g., FOB, CIF) early in negotiations and ensure packaging meets destination customs and handling standards.

Are free samples available for CNC machined parts?

Sample policies vary. Some suppliers offer paid samples refundable against future orders, while others provide complimentary samples for qualified buyers with confirmed purchase intent. Expect sample costs to reflect material and setup expenses, particularly for non-standard alloys or tight-tolerance features.

How to submit design files for quoting?

Provide detailed 2D drawings with GD&T callouts and 3D CAD models (STEP, IGES, or SLDPRT formats). Include specifications for material grade, surface finish, heat treatment, and any functional testing requirements. Reputable suppliers will return DFM feedback within 24–48 hours.