Cnc Machines

Top sponsor listing

Top sponsor listing

1/28

1/28

1/14

1/14

1/16

1/16

1/14

1/14

1/13

1/13

1/16

1/16

1/21

1/21

1/1

1/1

1/5

1/5

1/2

1/2

1/10

1/10

1/9

1/9

1/13

1/13

About cnc machines

Where to Find CNC Machines Suppliers?

China remains the global epicenter for CNC machine manufacturing, with concentrated industrial hubs in Jiangsu, Shandong, and Liaoning provinces driving innovation and scale. Jiangsu hosts advanced machining centers specializing in 5-axis and ATC (Automatic Tool Changer) systems, leveraging proximity to Shanghai’s logistics network for rapid export fulfillment. Shandong, particularly Jinan, is renowned for wood and advertising CNC routers, supported by a robust ecosystem of component suppliers focusing on spindles, control systems, and vacuum tables. Dalian in Liaoning province contributes precision metal-cutting solutions, including CNC lathes and machining centers tailored for aerospace and automotive sectors.

These regional clusters enable vertically integrated production—spanning casting, CNC milling, assembly, and testing—within compact geographic zones. This integration reduces lead times by up to 30% compared to decentralized models. Buyers benefit from localized supply chains that support MOQ flexibility, rapid prototyping, and customization scalability. Typical delivery windows range from 15–45 days depending on complexity, with cost advantages of 20–40% over European or North American manufacturers due to lower labor and operational overheads.

How to Choose CNC Machines Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify ISO 9001 certification as a baseline for quality management systems. For international compliance, ensure CE marking aligns with EU machinery directives. Suppliers should provide documentation for spindle performance, control system compatibility (e.g., NC Studio, Mach3), and electrical safety standards. Laser and plasma-based models must meet IEC 60825 and IEC 60204-1 requirements respectively.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house engineering teams capable of customizing worktable size, spindle power, and automation features

- Integrated fabrication capabilities including welding, gantry assembly, and software integration

Cross-reference response time (target ≤2 hours) and on-time delivery rates (>97%) as indicators of operational efficiency and order prioritization.

Customization & Quality Assurance

Confirm scope of customization: working area dimensions, material compatibility (wood, MDF, aluminum, steel, acrylic), cooling methods (air/water), and tooling options (ATC, oscillating knife, rotary attachments). Require sample testing prior to full procurement, especially for nesting or multi-head configurations. Validate dust collection, noise levels (<80 dB), and software interface usability during trials.

Transaction Security & Export Readiness

Prioritize suppliers with verifiable export histories and participation in trade assurance programs. Use escrow payment terms until equipment passes destination inspection. Assess after-sales support capacity, including remote diagnostics, spare parts availability, and multilingual technical guidance.

What Are the Best CNC Machines Suppliers?

| Company Name | Main Products | Verified Supplier Type | On-Time Delivery | Reorder Rate | Avg. Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

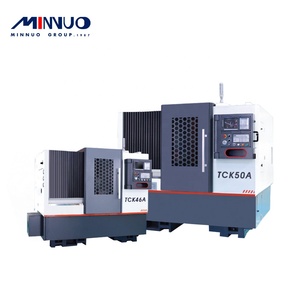

| Jiangsu Minnuo Group Co., Ltd. | Machining Centre, CNC Lathe, Industrial Compressors | Custom Manufacturer | 100% | 57% | ≤2h | US $5,700,000+ | Color, material, size, logo, packaging, 5-axis table, power, graphic |

| Alpha Cnc Co., Ltd. | CNC Wood Carving, Engraving, Sheet Metal Machines | Multispecialty Supplier | 100% | 58% | ≤1h | US $1,300,000+ | Size, motor, precision, T-slot table, ATC, vacuum pump, spindle power, cooling method |

| Jinan Mingshi Machinery Equipment Co., Ltd. | ATC Nesting Line, Vacuum Table CNC Router | Custom Manufacturer | 100% | 21% | ≤1h | US $300,000+ | Working size, vacuum suction, oscillating knife, control system, servo motors, multiple heads, software language |

| Shandong Xunke Cnc Machine Co., Ltd. | Wood Furniture ATC, Plasma Cutter, Gantry CNC | Custom Manufacturer | 100% | <15% | ≤2h | US $130,000+ | Engraving depth, configuration, spindle power, control software, material type, logo, packaging |

| Dalian Golden Machinery Co., Ltd. | 5-Axis Machining Center, CK6150 CNC Lathe | Multispecialty Supplier | 100% | 50% | ≤1h | US $50,000+ | Color, material, size, logo, graphic |

Performance Analysis

Jiangsu Minnuo and Alpha Cnc stand out for high reorder rates (57% and 58%) and substantial online revenue, indicating strong market trust and export volume. Both offer extensive customization and fast response cycles, making them suitable for mid-to-large volume buyers requiring technical adaptability. Alpha Cnc excels in responsiveness (≤1h), a critical factor for urgent quoting and design iterations.

Jinan Mingshi focuses on advanced furniture production lines with ATC and automatic loading systems, though its lower reorder rate suggests room for improvement in post-sale engagement. Shandong Xunke offers competitive pricing but has limited repeat business, potentially reflecting niche positioning or service gaps. Dalian Golden Machinery targets precision metalworking with high-value 5-axis machines priced up to $35,790, catering to specialized industrial applications.

All five suppliers maintain 100% on-time delivery, underscoring operational reliability. However, buyers should verify actual production capacity through facility audits—especially for suppliers with smaller reported revenues—to avoid overcommitment risks.

FAQs

How to verify CNC machine supplier reliability?

Cross-check ISO and CE certifications with issuing bodies. Request factory audit reports or video tours confirming in-house machining, assembly lines, and quality control stations. Analyze customer reviews focusing on machine accuracy, software stability, and long-term durability under continuous operation.

What is the average lead time for CNC machines?

Standard models typically ship within 15–25 days after order confirmation. Customized units with ATC, nesting conveyors, or dual worktables require 30–45 days. Add 7–14 days for international sea freight or 3–7 days for air cargo.

Can suppliers accommodate low MOQs?

Yes, most suppliers accept MOQs of 1 set, particularly for standard router or lathe models. However, unit prices decrease significantly at volumes above 5 sets. Confirm packaging and crating details to ensure safe transport for single-unit shipments.

Do manufacturers support OEM/ODM services?

Custom manufacturers like Jiangsu Minnuo and Shandong Xunke offer full OEM branding—including logos, color schemes, control panels, and user manuals. ODM support includes modifying worktable sizes, integrating third-party spindles (e.g., HSD, Huanyang), and adapting software interfaces (e.g., Syntec, Siemens).

How to initiate a customization request?

Submit detailed specifications covering required working dimensions (e.g., 1300x2500mm), spindle power (3kW–9kW), tool magazine capacity (if ATC), material types processed, and desired automation level. Reputable suppliers respond with CAD drawings or 3D renderings within 48–72 hours and can produce functional prototypes within 3–4 weeks.