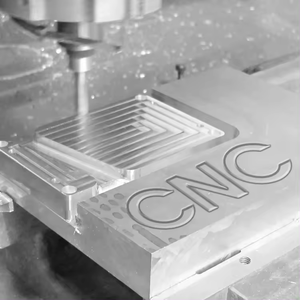

Cnc Machining Definition

CN

CN

Top sponsor listing

Top sponsor listing

1/3

1/3

1/32

1/32

0

0

1/2

1/2

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/16

1/16

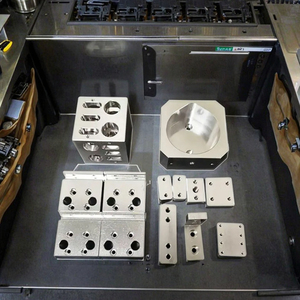

About cnc machining definition

Where to Find CNC Machining Definition Suppliers?

China remains the global epicenter for precision CNC machining services, with supplier clusters concentrated in industrial hubs such as Shanghai, Dongguan, and Zhuhai. These regions host vertically integrated manufacturing ecosystems that combine advanced machining infrastructure with agile prototyping capabilities. Shanghai-based suppliers benefit from proximity to R&D centers and international logistics gateways, enabling rapid iteration for export-oriented buyers. Meanwhile, Guangdong’s Dongguan-Zhuhai corridor specializes in high-mix, low-volume production, supporting complex custom components across aerospace, medical, and automation sectors.

The regional supply chains offer significant cost efficiency—localized access to raw materials (including SS304, aluminum alloys, and engineering plastics) reduces material procurement lead times by 20–30%. Integrated fabrication networks allow seamless transitions between CNC turning, milling, EDM, and sheet metal operations within a single facility. Buyers can expect standard lead times of 15–25 days for prototype batches and 30–45 days for volume orders, with many suppliers offering expedited processing for urgent requests.

How to Choose CNC Machining Definition Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

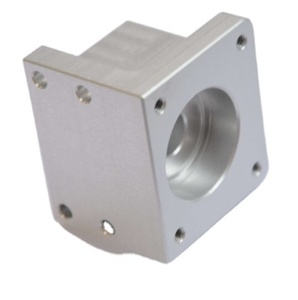

Technical Capabilities Verification

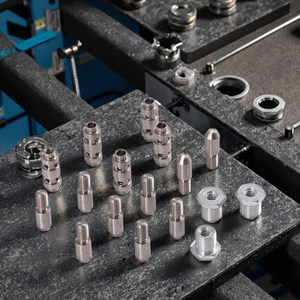

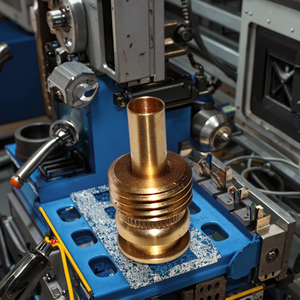

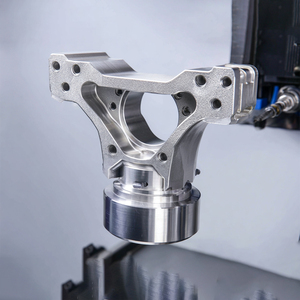

Confirm the supplier’s mastery of multi-axis machining (3-axis, 4-axis, 5-axis) and secondary processes such as anodizing, plating, or laser engraving. For mission-critical applications, verify availability of coordinate measuring machines (CMM) and first-article inspection reports. Suppliers advertising "high-precision" services should demonstrate tolerances down to ±0.005 mm under controlled conditions.

Production Infrastructure Assessment

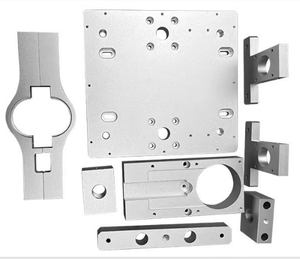

Evaluate key operational indicators:

- Minimum factory area exceeding 1,000m² for sustained output capacity

- In-house design and engineering support for DFM (Design for Manufacturing) feedback

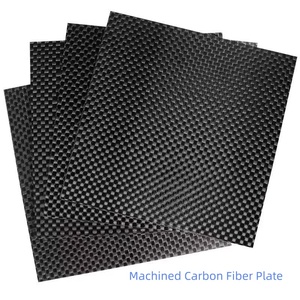

- Demonstrated capability in both ferrous (steel, stainless steel) and non-ferrous (aluminum, brass, titanium) materials

Cross-reference service claims with on-time delivery performance (target ≥95%) and response time metrics (≤2 hours preferred).

Quality & Transaction Assurance

Prioritize suppliers with documented quality management systems—ISO 9001 certification is a baseline indicator. While not always explicitly stated, consistent reorder rates above 20% suggest customer satisfaction and process reliability. Utilize digital verification tools where available, focusing on order fulfillment history and dispute resolution records. Prototyping remains critical: request sample parts to validate surface finish, dimensional accuracy, and compliance with technical drawings before scaling production.

What Are the Best CNC Machining Definition Suppliers?

| Company Name | Location | Supplier Type | Main Services | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shanghai Fangyou Precision Machinery Co., Ltd. | Shanghai, CN | Custom Manufacturer | Machining Services, Sheet Metal Fabrication, Moulds, Casting, Forging | 100% | ≤1h | US $10,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

| 24K Investment (Qingdao) Co., Ltd. | Qingdao, CN | - | Machining Services, Sheet Metal Fabrication, Moulds, Casting | 94% | ≤2h | US $10,000+ | 21% | - |

| Shanghai Yongzhen Machine Components Co., Ltd. | Shanghai, CN | Multispecialty Supplier | Machining Services, Sheet Metal Fabrication, Moulds, Casting | 95% | ≤3h | US $20,000+ | <15% | Color, material, size, metal parts, drawing, logo, packaging, label, graphic, SS304 |

| Dongguan Puruigen Metal Products Co., Ltd. | Dongguan, CN | Custom Manufacturer | Precision CNC Machining, Prototype Development | 100% | ≤1h | US $1,000+ | 60% | Color, size, logo, packaging, label, graphic |

| Zhuhai Mingjiang Machinery Technology Co., Ltd. | Zhuhai, CN | - | Machining Services | 100% | ≤12h | - | - | - |

Performance Analysis

Shanghai-based suppliers like Fangyou Precision and Yongzhen Machine Components demonstrate strong integration across multiple fabrication disciplines, making them suitable for full-package manufacturing solutions. Dongguan Puruigen stands out with a 60% reorder rate—the highest among listed suppliers—indicating robust customer retention likely driven by responsive communication and consistent quality. Despite lower reported online revenue, its specialization in aluminum and stainless steel prototypes aligns well with innovation-driven industries.

Notably, three suppliers maintain perfect on-time delivery records (100%), suggesting disciplined production planning. However, response times vary significantly—from under one hour to up to 12 hours—highlighting the importance of real-time communication for time-sensitive projects. Buyers requiring extensive customization should prioritize suppliers listing specific options such as material grade selection (e.g., SS304), DFX support, and labeling services.

FAQs

How to verify CNC machining supplier reliability?

Validate technical competence through facility videos, equipment lists, and sample inspection reports. Request evidence of quality control procedures, including incoming material checks, in-process inspections, and final QA testing. Analyze historical performance data such as on-time delivery rates and customer reorder behavior as proxies for operational stability.

What is the typical MOQ and pricing structure?

Minimum Order Quantities range from 1 piece (prototypes) to 50–100 pieces for batch production. Unit prices typically fall between $0.01 and $15, depending on complexity, material, and finishing requirements. Low-MOQ flexibility is common among suppliers targeting R&D and startup markets.

Can CNC machining suppliers handle full customization?

Yes, most suppliers support end-to-end customization including geometry, material specification, surface treatment, branding (logo/label), and packaging. Advanced providers offer DFM analysis and 3D modeling support to optimize manufacturability prior to production.

Do suppliers provide samples or prototypes?

Prototype services are widely available, often at nominal cost or waived upon order confirmation. Lead times for sample production average 7–14 days, depending on part complexity. Buyers are advised to conduct dimensional and functional validation before approving mass production.

Are there logistics advantages when sourcing from specific regions?

Yes. Shanghai and Qingdao offer superior air and sea freight connectivity, reducing transit times to Europe and North America by 5–7 days compared to inland regions. Suppliers in these zones often manage door-to-door shipping under FOB or CIF terms, simplifying international procurement.