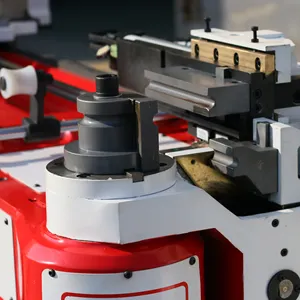

Cnc Pipe Bending Machine Price In India

CN

CN

CN

CN

CN

CN

About cnc pipe bending machine price in india

Where to Find CNC Pipe Bending Machine Suppliers?

China remains the leading global source for CNC pipe bending machines, with concentrated manufacturing expertise in Jiangsu and Henan provinces. Zhangjiagang—located in Jiangsu—hosts a specialized industrial cluster for metal forming machinery, offering vertically integrated production from raw material processing to final assembly. This region benefits from proximity to steel suppliers and export ports, reducing logistics lead times by 10–15% compared to inland manufacturers. Henan-based producers leverage cost-efficient labor and scalable facilities, making them competitive for entry-level and mid-range CNC models.

Suppliers in these regions typically operate multi-disciplinary workshops equipped with CNC machining centers, hydraulic testing rigs, and automated welding stations. The ecosystem supports rapid prototyping and batch production, with average monthly output ranging from 30 to 100 units per facility depending on automation level. Buyers gain access to flexible configurations including 3-axis full automation, NC semi-automatic systems, and mandrel-free designs suitable for stainless steel, aluminum, and carbon steel pipes. Typical delivery windows range from 25 to 45 days for standard orders, with express production available at +15–20% cost premium.

How to Choose CNC Pipe Bending Machine Suppliers?

Adopt structured evaluation criteria to mitigate procurement risk:

Technical Compliance

Confirm adherence to international safety and performance benchmarks. While not all suppliers list ISO 9001 certification explicitly, prioritize those demonstrating quality management through consistent on-time delivery (target ≥90%) and documented testing procedures. For operations in regulated sectors (e.g., automotive or medical devices), verify machine compatibility with CE or equivalent electrical and mechanical safety standards.

Production Capability Audits

Assess operational scale and technical depth using verifiable indicators:

- Minimum of 20+ product listings in pipe and tube bending category indicating market specialization

- In-house engineering support for custom parameters: bend radius, tube diameter (up to 3 inches), wall thickness, and material flexibility (round, square, oval, rectangular profiles)

- Provision of 3D simulation, remote monitoring, and digital twin modeling for complex bends

- Cross-reference response time (≤2 hours preferred) with reorder rates as proxies for service reliability

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services to ensure conditional release upon inspection. Request sample testing for critical applications—especially when specifying tight tolerances (<±0.5° angular deviation) or high-cycle durability. Evaluate packaging standards and export documentation readiness, particularly for Indian customs compliance where import codes under HS 8462.21 may apply.

What Are the Best CNC Pipe Bending Machine Suppliers?

| Company Name | Main Products (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang KING-MACC Machinery Manufacturing Co., Ltd. | Pipe & Tube Bending Machines (51) | $5,800–40,000 | 1 unit/set | 100% | ≤1h | - | Limited | - |

| Zhangjiagang Sanco Machinery Co., Ltd. | Pipe & Tube Bending Machines (varied) | $10,000–150,000 | 1 set | 90% | ≤5h | 60% | High (material, shape, curvature, drawings) | US $1.1M+ |

| Zhangjiagang Runtai Machinery Co., Ltd. | Pipe & Tube Bending Machines (23) | $4,200–23,800 | 1 set | - | ≤6h | <15% | Moderate | - |

| Henan Pand Machinery Equipment Co., Ltd. | Pipe & Tube Bending Machines (105) | $200–1,750 | 1 set | 100% | ≤2h | <15% | Limited | US $160K+ |

| Suzhou Hope Trend Import & Export Co., Ltd. | Pipe & Tube Bending Machines (varied) | $4,300–10,000 | 1–2 sets | 100% | ≤1h | 25% | Basic (color, logo, size) | US $110K+ |

Performance Analysis

Zhangjiagang Sanco Machinery stands out for high customization capability and strong reorder rate (60%), indicating customer satisfaction in engineered solutions despite slower response times. Zhangjiagang KING-MACC offers broad pricing coverage and proven on-time fulfillment, ideal for buyers seeking reliable volume supply. Henan Pand Machinery presents an outlier in pricing, listing compact or component-level benders below $2,000—suitable for niche retrofitting or small workshop use but not full-scale automation. Suzhou Hope Trend combines fast responsiveness with balanced pricing, serving mid-tier industrial demand efficiently. Runtai Machinery delivers competitive entry-point models (from $4,200) but lacks reorder metrics, suggesting potential gaps in post-sale support or consistency.

FAQs

What is the typical price range for CNC pipe bending machines in India?

Imported CNC pipe bending machines range from $200 for modular components to $150,000 for fully automated 3D bending systems. Standard industrial-grade machines fall between $8,000 and $40,000, depending on axis count, tube capacity, and control system sophistication.

Do suppliers offer customization for Indian market requirements?

Yes, especially for voltage specifications (415V/3-phase), local language HMI interfaces, and integration with existing production lines. High-end suppliers provide CAD/CAM integration and bending simulation based on client drawings.

What are common MOQ and lead time expectations?

MOQ is typically 1 set for standard models. Lead time averages 30–45 days post-deposit, with expedited options available. Some suppliers require 2 sets minimum for customized configurations.

Are samples available before bulk purchase?

Sample availability varies. Some suppliers offer functional demos via video or factory visits. Physical samples may incur partial charges, especially for high-value models, though fees are often deducted from subsequent orders.

How to assess machine compatibility with specific materials?

Provide detailed technical data: outer diameter (OD), wall thickness, material grade (e.g., SS304, ASTM A53), and desired bend radius. Reputable suppliers will simulate deformation behavior and recommend appropriate tooling or mandrel use to prevent wrinkling or ovalization.