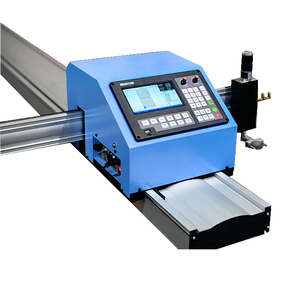

Cnc Plasma Cutting Table Distributor

About cnc plasma cutting table distributor

Where to Find CNC Plasma Cutting Table Suppliers?

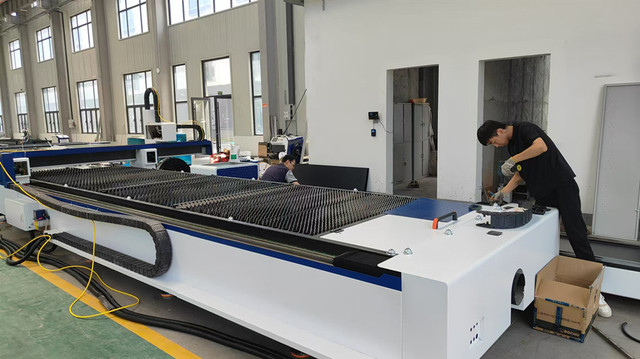

China remains the dominant hub for CNC plasma cutting table manufacturing, with key industrial clusters concentrated in Shandong and Anhui provinces. These regions host vertically integrated production ecosystems that combine precision machining, structural steel fabrication, and advanced control system integration. Shandong, particularly around Jinan and Linyi, specializes in high-precision gantry-style plasma tables with automated nesting software, leveraging proximity to major steel suppliers to reduce raw material costs by 15–20%. Anhui’s machinery corridor supports heavy-duty industrial builds, offering scalable production lines capable of delivering standard and custom configurations within compressed lead times.

The clustering effect enables efficient component sourcing—linear guides, servo motors, plasma power sources, and CNC controllers are available from localized suppliers within 50 km, reducing assembly delays. Buyers benefit from shorter production cycles (typically 25–40 days for 1–5 unit orders), competitive pricing due to economies of scale, and access to manufacturers with proven export experience across North America, Europe, and Southeast Asia. The region's mature logistics infrastructure ensures reliable FOB coordination through Qingdao, Shanghai, and Ningbo ports.

How to Choose CNC Plasma Cutting Table Suppliers?

Selecting a qualified supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international safety and performance standards, including CE marking for European markets and compliance with electrical safety norms (IEC 60204-1). Request documentation on plasma source compatibility (e.g., Hypertherm, Huarui), motion control systems (e.g., DSP, Mach3, or proprietary CNC), and structural integrity testing of the frame under continuous load conditions.

Production Capability Audits

Assess core manufacturing competencies through verifiable indicators:

- Minimum factory footprint of 3,000m² to support dedicated cutting, welding, and assembly zones

- In-house CNC machining and gantry rail alignment capabilities to ensure ±0.1mm/m accuracy

- Integration capacity for multi-process systems (plasma, flame, laser) and automation interfaces

- On-time delivery rate exceeding 93% as an indicator of production planning reliability

Cross-reference online transaction data with response time metrics (target ≤2 hours) and reorder rates to gauge customer satisfaction and post-sale support effectiveness.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial procurement. Prioritize suppliers with transparent order tracking, third-party inspection acceptance, and clear warranty terms (typically 12 months on structural components and control systems). Pre-shipment inspections should include dry-run operation tests and calibration verification using laser alignment tools.

What Are the Best CNC Plasma Cutting Table Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Price Range (USD) | Notable Features |

|---|---|---|---|---|---|---|---|---|

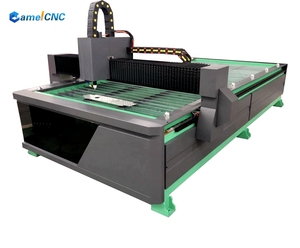

| Shandong Camel Cnc Machinery Co., Ltd. | Shandong, CN | US $30,000+ | 100% | <15% | ≤3h | Color, material, size, logo, packaging, graphic | $2,000–5,480 | Budget-friendly entry models; consistent delivery |

| Shandong Rayman Machinery Co., Ltd. | Shandong, CN | US $430,000+ | 93% | 25% | ≤1h | Cutting area, thickness, gantry type, power, material | $1,100–3,700 | Highest responsiveness; broad customization scope |

| Jinan Remax Machinery Technology Co., Ltd. | Shandong, CN | US $40,000+ | 100% | <15% | ≤2h | Limited customization noted | $4,200–9,000 | Premium segment; large-format and high-power models |

| Anhui Runbang Heavy Industry Machinery Co., Ltd. | Anhui, CN | US $240,000+ | 100% | 28% | ≤2h | Size, thickness, gantry, laser option, material | $1,200–5,100 | Mid-range versatility; strong after-sales engagement |

| Jinan Smart Technology Co., Ltd. | Shandong, CN | US $330,000+ | 100% | 44% | ≤2h | Color, material, size, logo, packaging, graphic | $3,000–5,000 | Highest reorder rate; balanced price-to-performance ratio |

Performance Analysis

Shandong-based suppliers dominate in delivery consistency, with three out of five achieving 100% on-time fulfillment. Jinan Smart Technology stands out with a 44% reorder rate, indicating strong customer retention likely driven by responsive service and reliable machine performance. Shandong Rayman leads in responsiveness (≤1h average reply time) and offers extensive configuration options, making it ideal for buyers requiring tailored cutting envelopes or hybrid plasma-flame setups. For cost-sensitive buyers, Anhui Runbang and Shandong Rayman provide competitively priced models starting below $1,200 per set without compromising structural quality. High-end applications demanding extended bed sizes (up to 2000x6000mm) and 200A+ plasma capacity are best served by Jinan Remax, despite its higher price point.

FAQs

How to verify CNC plasma cutting table supplier reliability?

Validate certifications (CE, ISO 9001) through official registries and request test reports for critical subsystems. Conduct virtual factory audits to observe welding quality, rail installation precision, and final assembly procedures. Analyze transaction history for consistent order volume and dispute resolution outcomes.

What is the typical lead time for CNC plasma tables?

Standard units require 25–35 days for production and pre-shipment inspection. Customized configurations with non-standard dimensions or dual torch setups may extend to 45 days. Air freight samples can arrive in 7–10 days; sea freight transit averages 20–30 days depending on destination port.

Do suppliers offer customization options?

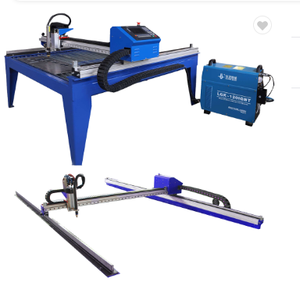

Yes, most suppliers support modifications to table dimensions (common ranges: 1500x3000mm to 2000x6000mm), gantry height, material thickness capacity (6–50mm), control systems, and branding elements. Advanced options include integrated fume extraction, automatic height control (AHC), and multi-axis rotary attachments.

What are common MOQ and pricing structures?

Minimum Order Quantity is typically 1 set, enabling low-volume trial purchases. Prices range from $1,100 for basic 1530 models to over $9,000 for heavy-duty industrial systems. Volume discounts generally apply at 3+ units, with incremental savings of 5–12% based on order size.

Can suppliers handle global shipping and customs clearance?

Established exporters manage end-to-end logistics under FOB, CIF, or DAP terms. Confirm inclusion of export documentation (packing list, commercial invoice, bill of lading) and compliance with destination-country electrical and machinery import regulations. Pre-shipment container loading supervision is recommended for full-container loads.