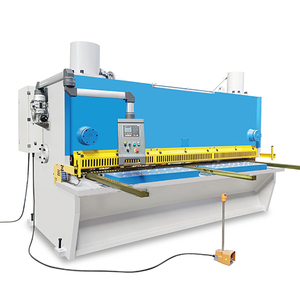

Cnc Shearing Machine Price In India

1/18

1/18

CN

CN

1/23

1/23

1/15

1/15

1/31

1/31

1/27

1/27

1/20

1/20

1/11

1/11

1/21

1/21

1/11

1/11

1/22

1/22

1/16

1/16

1/16

1/16

CN

CN

1/28

1/28

About cnc shearing machine price in india

Where to Find CNC Shearing Machine Suppliers?

China remains the global hub for CNC shearing machine production, with concentrated manufacturing clusters in Anhui, Jiangsu, and Nanjing provinces offering competitive advantages in cost, scalability, and technical specialization. Anhui Province hosts a growing number of sheet metal processing equipment manufacturers, leveraging localized supply chains for hydraulic components and CNC control systems. Jiangsu-based suppliers benefit from proximity to Suzhou’s advanced industrial automation ecosystem, enabling integration of Estun, E21S, and ELGO control technologies into standard machine configurations.

These regional hubs support vertically integrated production models—spanning raw material sourcing, precision machining, welding, and final assembly—within compact geographic zones. This integration reduces component procurement lead times by 20–30% compared to decentralized manufacturing regions. Buyers gain access to suppliers capable of fulfilling orders within 30–45 days for standard configurations, with economies of scale driving production costs 15–25% below Western benchmarks. The presence of established export channels ensures compliance-ready machinery for international markets, particularly India, Southeast Asia, and the Middle East.

How to Choose CNC Shearing Machine Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Verification

Confirm integration of recognized CNC systems (e.g., Estun, E21S) and compliance with ISO 9001 quality standards. For operations requiring high repeatability, validate machine accuracy specifications—typically ±0.1mm over 3200mm cutting length. Hydraulic system performance should meet or exceed 20 MPa operating pressure, with response time under 0.3 seconds per cycle. Request test reports for critical components including torsion shafts, blades, and backgauges.

Production Infrastructure Assessment

Evaluate key operational indicators:

- Minimum factory area of 3,000m² to ensure stable output capacity

- In-house CNC machining and welding capabilities to maintain process control

- Dedicated R&D teams supporting customization (e.g., blade hardness, stroke adjustment, interface programming)

Cross-reference on-time delivery rates (target ≥95%) with order volume history to assess reliability under load.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as third-party escrow until post-delivery inspection is completed. Prioritize suppliers with documented quality control processes and verified after-sales service networks. Pre-shipment inspections should include dry-run testing, dimensional verification, and software functionality checks. Sample validation is recommended for custom configurations to confirm material compatibility (up to 6mm mild steel, 4mm stainless) and cutting precision.

What Are the Best CNC Shearing Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Suzhou Myt Cnc Machine Co., Ltd. | Jiangsu, CN | US $2,100,000+ | 84% | ≤5h | <15% | $10,500–28,000 | Color, material, size, logo, packaging, label, graphic | Multispecialty Supplier |

| Nanjing Raymax Trading Co., Ltd. | Nanjing, CN | US $2,000+ | 100% | ≤2h | <15% | $4,500–15,620 | Color, material, size, logo, packaging, label, graphic | Custom Manufacturer |

| Anhui Colgar Machinery Manufacturing Co., Ltd. | Anhui, CN | US $160,000+ | 100% | ≤2h | 33% | $5,500–6,800 | Not specified | Multispecialty Supplier |

| Anhui Aoxuan Heavy Industry Machine Co., Ltd. | Anhui, CN | US $330,000+ | 100% | ≤3h | 21% | $2,800–13,400 | Color, material, size, logo, packaging, label, packing, graphic | Multispecialty Supplier |

| Hefei Zhixin Machinery Co., Ltd. | Anhui, CN | US $20,000+ | 100% | ≤2h | <15% | $1,000–7,000 | Not specified | Not specified |

Performance Analysis

Suppliers like Anhui Colgar and Nanjing Raymax demonstrate exceptional reliability with 100% on-time delivery and sub-3-hour average response times, indicating robust internal coordination. Anhui Colgar stands out with a 33% reorder rate—the highest among listed suppliers—suggesting strong customer satisfaction despite mid-range pricing. Nanjing Raymax offers the broadest price segmentation, catering to both entry-level ($4,500) and mid-tier ($15,620) buyers with consistent delivery performance. Suzhou Myt provides premium options up to $28,000, reflecting higher build quality or advanced CNC integration, though its 84% on-time rate warrants closer logistics scrutiny. Hefei Zhixin presents the most aggressive pricing at $1,000–$1,500 for basic mechanical models, suitable for budget-conscious buyers prioritizing cost over automation level.

FAQs

What is the typical MOQ and lead time for CNC shearing machines?

Standard minimum order quantity is 1 set, with lead times ranging from 20 to 40 days depending on customization complexity. Stock models with preconfigured CNC systems ship faster, while bespoke units with modified bed lengths or control interfaces may require additional programming and testing time.

Do suppliers offer customization for Indian market requirements?

Yes, multiple suppliers provide voltage adaptation (380V/50Hz standard), local language HMI panels, and CE-compliant safety enclosures. Customization extends to cutting capacity (e.g., 6x4000mm, 8x6000mm), blade material (Cr12MoV), and integration with downstream automation systems.

How are CNC shearing machines packaged for export to India?

Machines are typically secured in seaworthy wooden crates with anti-corrosion coating and shock-absorbing mounts. Export documentation includes packing list, commercial invoice, bill of lading, and conformity certificates. FOB Shanghai/Ningbo is common; CIF Chennai/Mumbai is available upon request.

Can buyers inspect machines before shipment?

Pre-shipment inspection is standard practice. Buyers may conduct remote video audits or dispatch third-party inspectors to verify machine operation, component origin, and calibration. Some suppliers offer trial runs with sample materials to confirm cutting accuracy and repeatability.

What after-sales support is typically provided?

Most suppliers offer one-year warranty on structural and hydraulic components, along with technical guidance via email, phone, or remote diagnostics. Advanced vendors provide installation supervision, operator training, and spare parts supply agreements to minimize downtime.