Cnc Spindle

Top sponsor listing

Top sponsor listing

1/17

1/17

1/20

1/20

1/17

1/17

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/16

1/16

1/3

1/3

1/3

1/3

1/5

1/5

1/11

1/11

1/11

1/11

1/16

1/16

0

0

0

0

About cnc spindle

Where to Find CNC Spindle Suppliers?

China remains the global hub for CNC spindle manufacturing, with key production clusters in Guangdong, Shandong, and Zhejiang provinces. These regions host vertically integrated supply chains that support precision machining, motor assembly, and frequency drive integration—critical components in high-performance spindle systems. Foshan (Guangdong) and Jinan (Shandong) have emerged as focal points due to their concentration of motor technology firms and proximity to CNC router and machine tool manufacturers.

The industrial ecosystems in these zones enable streamlined component sourcing, reducing lead times by up to 25% compared to offshore alternatives. Local suppliers benefit from established partnerships with bearing, stator, and cooling system producers, allowing rapid prototyping and scalable production. Average monthly output across verified manufacturers ranges from 500 to 2,000 units, depending on power rating and cooling type (air vs. water-cooled). This infrastructure supports both standardized models and engineered-to-order spindles with custom shaft configurations, voltage specifications, and interface compatibility (e.g., ER20, ER32).

How to Choose CNC Spindle Suppliers?

Selecting reliable partners requires a structured evaluation of technical, operational, and transactional indicators:

Technical and Production Capabilities

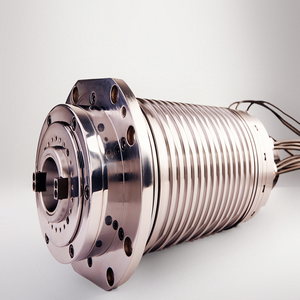

Assess whether suppliers possess in-house engineering and testing facilities. Key markers include design expertise in variable frequency drivers (VFD), thermal management systems, and dynamic balancing (up to 18,000–24,000 RPM). Prioritize manufacturers offering customization across material selection (aluminum alloy housings, stainless steel shafts), color coding, labeling, and packaging. Verified custom manufacturers typically support modifications to speed range, power output (0.8kW to 9kW), and mounting dimensions.

Quality and Compliance Verification

While explicit ISO or CE certifications are not disclosed in available data, performance metrics serve as proxies for quality control rigor. Top-tier suppliers report on-time delivery rates exceeding 98%, response times under 2 hours, and reorder rates above 30%—indicative of consistent product reliability and post-sale satisfaction. Buyers should request test reports for insulation resistance, vibration levels, and continuous operation endurance (minimum 72-hour burn-in tests).

Transaction and Risk Mitigation

Leverage digital procurement safeguards such as milestone-based payments and shipment inspections. Analyze online revenue history (e.g., US$270,000+ annual volume) as an indicator of market acceptance and financial stability. High reorder rates (≥30%) correlate with long-term supplier dependability. For new engagements, initiate with sample orders to validate performance against specified load and speed parameters before scaling procurement.

What Are the Best CNC Spindle Suppliers?

| Company Name | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Jinan Hard Bar Carving Tools Co., Ltd. | Custom Manufacturer | CNC Spindle, Air-Cooled & Water-Cooled Models | US $270,000+ | 99% | ≤2h | 33% | Color, Material, Size, Logo, Packaging | 1 piece |

| Dongyang Lizhi Motor Co., Ltd. | Multispecialty Supplier | Air-Cooled Spindles (1.5KW–7.5KW) | US $20,000+ | 98% | ≤2h | <15% | Size, Material, Label, Graphic | 1–2 pieces |

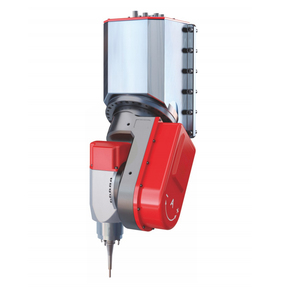

| Suzhou Penny Machinery Equipment Co., Ltd. | Custom Manufacturer | ATC Spindles, Water-Cooled Units, VFDs | US $160,000+ | 84% | ≤6h | <15% | Full Customization (Shaft, Power, Cooling) | 1 piece |

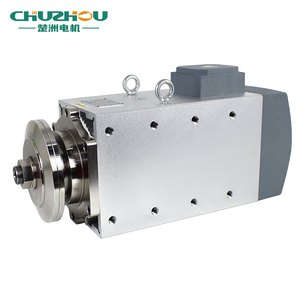

| Foshan Chuzhou Motor Technology Co., Ltd. | Custom Manufacturer | Machine Tool Spindles, VFD Drivers | US $30,000+ | 85% | ≤5h | 16% | Material, Logo, Packaging, Label | 1 piece |

Performance Analysis

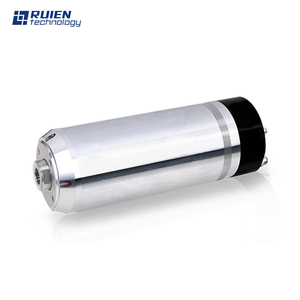

Jinan Hard Bar Carving Tools stands out with a 99% on-time delivery rate and 33% customer reorder rate, indicating strong operational efficiency and product consistency. Its broad price range ($7.50–$208) accommodates entry-level and mid-tier applications, including router and engraving machines. Dongyang Lizhi Motor offers competitive pricing and fast responsiveness but has a lower reorder rate, suggesting potential gaps in long-term satisfaction or niche positioning.

Suzhou Penny Machinery specializes in higher-power ATC (Automatic Tool Change) spindles (6kW–9kW), catering to advanced CNC automation setups. Despite a moderate 84% on-time delivery rate, its extensive customization capability and focus on integrated systems (spindle + controller + VFD) make it suitable for engineered solutions. Foshan Chuzhou Motor Technology provides standard air-cooled models with moderate output volume, appropriate for small-scale integrators requiring basic OEM branding.

FAQs

What is the typical minimum order quantity for CNC spindles?

Most suppliers list a minimum order of 1 piece, facilitating prototyping and low-volume integration. Bulk pricing typically applies at 5+ units, with discounts varying by power rating and customization level.

How long does it take to receive a sample?

Sample lead time averages 7–15 days after specification confirmation. Shipping via express courier adds 3–7 days internationally. Complex customizations may extend timelines to 25 days.

Can CNC spindles be customized for specific machine integration?

Yes, leading suppliers support mechanical and electrical customization, including flange types, shaft diameter, encoder integration, and VFD matching. Technical drawings or CAD files are required to initiate modification workflows.

What cooling types are available?

Air-cooled spindles dominate the market for general-purpose routers (1.5kW–7.5kW), while water-cooled variants are preferred for continuous-duty applications requiring noise reduction and thermal stability. Both types are widely available across supplier portfolios.

Do suppliers provide technical documentation and after-sales support?

Reputable manufacturers supply operation manuals, wiring diagrams, and troubleshooting guides. Post-sale support varies—prioritize suppliers with sub-2-hour response times for critical deployment scenarios. Video-assisted audits can verify service readiness prior to contract award.