Cnc Turning Machine

Top sponsor listing

Top sponsor listing

1/9

1/9

1/3

1/3

1/18

1/18

1/28

1/28

1/3

1/3

1/17

1/17

1/3

1/3

0

0

1/16

1/16

1/7

1/7

1/24

1/24

1/11

1/11

0

0

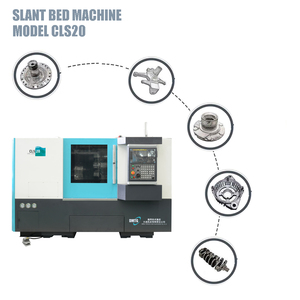

About cnc turning machine

Where to Find CNC Turning Machine Suppliers?

China remains the global hub for CNC turning machine manufacturing, with key industrial clusters concentrated in Liaoning and Shandong provinces. Dalian in Liaoning hosts a mature ecosystem of heavy machinery producers, specializing in high-precision horizontal and slant-bed CNC lathes. This region benefits from proximity to steel suppliers and deep-sea ports, enabling cost-efficient material sourcing and containerized shipping. Shandong’s Taian and Jining zones focus on compact and entry-level CNC turning centers, leveraging localized component networks to deliver competitively priced machines.

These clusters support vertically integrated production, where casting, machining, assembly, and testing occur within consolidated facilities. Buyers gain access to streamlined supply chains that reduce lead times to 45–60 days for standard configurations. Economies of scale allow for 20–30% lower unit costs compared to European or North American manufacturers, particularly for batch orders exceeding 5 units. The presence of technical talent and established export logistics further enhances reliability for international procurement.

How to Choose CNC Turning Machine Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Technical and Production Capacity

Prioritize suppliers with documented engineering capabilities and modern infrastructure. Key indicators include dedicated R&D teams, multi-axis CNC machining lines, and in-house assembly processes. Facilities should cover a minimum of 3,000m² to ensure scalable output. Confirm availability of precision testing equipment such as laser alignment systems and dynamic load testers to validate machine accuracy and repeatability.

Quality Assurance and Compliance

Verify adherence to international quality standards. ISO 9001 certification is a baseline requirement for process control. For markets in Europe and North America, CE marking indicates compliance with safety, health, and environmental regulations. Request documentation for spindle runout tests, backlash measurements, and servo system calibration—critical parameters affecting machining precision.

Transaction Reliability and Support

Assess responsiveness and order fulfillment history. Target suppliers with response times under 2 hours and on-time delivery rates exceeding 95%. Reorder rates above 50% indicate strong customer satisfaction. Utilize transaction protection mechanisms where available. Pre-shipment inspections and sample validation are recommended, especially for customized configurations involving specific control systems (e.g., Fanuc, Siemens) or multi-axis integration.

What Are the Best CNC Turning Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Sample Product Range (USD) |

|---|---|---|---|---|---|---|---|

| Genertec Dalian Machine Tool (wafangdian) Co., Ltd. | Machining Centre (395), CNC Lathe (281) | 100% | 50% | ≤1h | US $810,000+ | Color, material, size, logo, packaging, label, graphic | $12,800–$29,800 |

| Taian Best Machinery Co., Ltd. | CNC Turning Machines (Multiple Models) | 100% | <15% | ≤2h | US $20,000+ | Color, material, size, logo, packaging, label, graphic | $4,000–$20,000 |

| Ganzhou Fuxing Technology Co., Ltd. | CNC Lathe (56), Machining Centre (120) | 100% | 75% | ≤3h | US $40,000+ | Used & Refurbished High-End Machines | $23,800–$105,000 |

| Dalian R&C Machinery Co., Ltd. | CNC Metal Lathes, 5-Axis Systems | 80% | 16% | ≤3h | US $690,000+ | Color, material, size, logo, packaging, label, graphic | $11,000–$27,500 |

Performance Analysis

Genertec Dalian Machine Tool demonstrates strong operational efficiency with 100% on-time delivery, rapid response times, and robust customization capacity, positioning it as a preferred partner for mid-to-high volume buyers. Ganzhou Fuxing Technology stands out with a 75% reorder rate, indicating high client retention, driven by its niche in refurbished premium-brand machines (e.g., MAZAK, OKUMA) ideal for cost-sensitive yet performance-critical applications. Taian Best Machinery offers the most competitive pricing, targeting budget-conscious buyers despite a lower reorder rate. Dalian R&C Machinery reports high online revenue but an 80% on-time delivery rate, suggesting potential fulfillment risks that warrant due diligence. Suppliers with sub-2-hour response times, such as Genertec and Taian Best, provide stronger communication reliability essential for project coordination.

FAQs

What is the typical MOQ for CNC turning machines?

The standard minimum order quantity is 1 set. Most suppliers accommodate single-unit orders, especially for trial purchases or custom configurations. Bulk discounts typically apply for orders of 3 or more units.

What lead time should buyers expect?

Production lead times range from 30 to 60 days depending on machine complexity and customization level. Standard models are generally ready within 45 days. Used or refurbished units may ship faster, often within 15–25 days after inspection and preparation.

Can CNC turning machines be customized?

Yes, common customization options include control systems (Fanuc, Siemens, Mitsubishi), spindle configurations, tool turret types, automation interfaces, and branding elements such as color, logo, and packaging. Some suppliers offer full OEM/ODM services with tailored mechanical designs.

Are used CNC turning machines reliable?

Refurbished machines from reputable suppliers can offer high value. Look for units with documented maintenance histories, reconditioned spindles, updated controls, and comprehensive testing reports. Machines from brands like MAZAK, DMG MORI, and OKUMA retain strong performance post-refurbishment.

What payment and logistics terms are common?

Common payment terms include T/T (30% deposit, 70% before shipment) and L/C at sight. FOB terms are standard; CIF is available upon request. Sea freight is typical for full-container loads, while air freight may be used for spare parts or urgent small shipments.