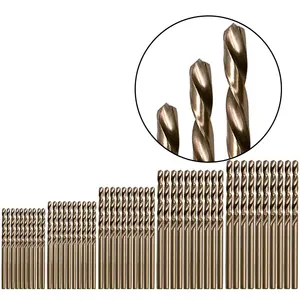

Cobalt Drill Bit Set Distributor

About cobalt drill bit set distributor

Where to Source Cobalt Drill Bit Set Distributors?

China remains the dominant hub for cobalt drill bit manufacturing, with key production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated tool factories specializing in high-speed steel (HSS) and M35 cobalt alloy processing, leveraging localized access to raw materials and precision machining infrastructure. Hangzhou and Shenzhen, in particular, have emerged as centers for export-oriented cutting tool suppliers, offering scalable production for distributors targeting industrial, automotive, and construction markets.

The regional ecosystems support cost-efficient manufacturing through consolidated supply chains—ranging from heat treatment facilities to CNC grinding lines—enabling competitive pricing and rapid order fulfillment. Suppliers in these zones typically maintain lean inventories with flexible retooling capabilities, allowing for both bulk procurement and customized configurations. Buyers benefit from average production lead times of 20–35 days, with established players demonstrating on-time delivery rates exceeding 97%. Localization reduces material costs by up to 25% compared to non-Asian producers, particularly for HSS-Co (M35) formulations requiring precise cobalt alloying (5–8%).

How to Evaluate Cobalt Drill Bit Set Suppliers?

Effective supplier assessment requires a structured approach focused on technical capability, quality assurance, and transactional reliability:

Material & Technical Specifications

Confirm use of M35 high-speed steel with 5% cobalt content for enhanced hardness (67–70 HRC) and thermal resistance. Verify production processes include vacuum heat treatment and precision flute grinding to ensure dimensional accuracy and chip evacuation efficiency. Request metallurgical test reports or batch certifications where available.

Quality Management Systems

Prioritize suppliers adhering to recognized quality standards. While ISO 9001 certification is not universally declared in the dataset, consistent on-time delivery (≥97%) and low defect rates are strong proxies for process control. Look for evidence of in-house inspection protocols, including runout testing and surface finish validation.

Production Capacity & Flexibility

Assess operational scale through key indicators:

- Minimum Order Quantity (MOQ) ranging from 1 set (for sample validation) to 500 sets (for volume orders)

- Customization capabilities: diameter range (1–13mm), shank type (straight or hex), coating (TiN, TiAlN), packaging, and branding

- Response time under 8 hours, with top-tier suppliers achieving ≤2h response rates

- Monthly online revenue exceeding US $200,000 as an indicator of market presence and order volume

Procurement Safeguards

Utilize secure payment terms such as escrow or milestone-based disbursements. Validate supplier claims through product sampling, focusing on edge retention, concentricity, and performance in hardened steel applications. Cross-reference reorder rates—ideally below 15% for commodity items—as a proxy for customer satisfaction and product consistency.

Top Cobalt Drill Bit Set Distributor Profiles

| Company Name | Location | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Moretop Tools Co., Ltd. | Zhejiang, CN | HSS-Cobalt, DIN338, Countersink Sets | Color, size, logo, packaging, material | US $340,000+ | 100% | ≤8h | <15% | 500 sets |

| Danyang Tongyu Tools Co., Ltd. | Jiangsu, CN | M35 Spot Weld, Left-Hand, Pilot Point | Not specified | US $340,000+ | 97% | ≤6h | <15% | 1 set |

| Shenzhen Ruizh Industrial Co., Ltd. | Guangdong, CN | Cobalt-Coated, M35, Adjustable Countersink | Color, size, logo, packaging, material | US $200,000+ | 100% | ≤2h | <15% | 10 pieces |

| Shenzhen Bwin Precision Tools Co., Ltd. | Guangdong, CN | OEM M35, Straight Shank, Metric Sets | Material, size, packaging, graphic | US $700,000+ | 100% | ≤2h | 39% | 1 piece |

| Jinan Terry Cnc Tool Limited Company | Shandong, CN | HSS-Co, M2/M35, Twist Drill Bits | Color, size, logo, packaging, material | US $160,000+ | 90% | ≤4h | 35% | 10 pieces |

Performance Analysis

Shenzhen Bwin Precision Tools stands out with the highest reported online revenue (US $700,000+) and the most flexible MOQ (1 piece), indicating strong e-commerce integration and responsiveness to small-batch demand. However, its 39% reorder rate suggests potential inconsistencies in long-term customer retention. In contrast, Hangzhou Moretop and Shenzhen Ruizh achieve 100% on-time delivery with sub-15% reorder rates, signaling reliable operations and stable product quality. Danyang Tongyu offers niche technical variants like left-hand and spot weld bits, catering to specialized repair and maintenance sectors. Jinan Terry, despite lower revenue, provides broad customization but lags in delivery performance (90%), warranting closer scrutiny for time-sensitive contracts.

FAQs

What is the typical MOQ for cobalt drill bit sets?

MOQ varies significantly by supplier, ranging from 1 set for sample testing to 500 sets for wholesale pricing. High-volume manufacturers often require 500-set minimums, while OEM-focused suppliers may accept single-piece orders for custom designs.

How long does production and shipping take?

Standard production lead time is 20–30 days after order confirmation. Air freight adds 5–10 days for international delivery, while sea shipping takes 25–40 days depending on destination. Expedited processing (10–15 days) is available from select suppliers at a premium.

Can suppliers provide custom branding and packaging?

Yes, multiple suppliers offer full customization including laser logo marking, color-coded packaging, branded blister cards, and private-label options. Minimum quantities for branding typically start at 100–500 units depending on complexity.

Are cobalt drill bits compliant with international standards?

Most suppliers produce to DIN338 or ANSI B94.11M specifications for geometry and tolerances. While explicit CE or RoHS declarations are not provided in the data, M35 cobalt bits are commonly used in EU and North American markets, suggesting de facto compliance with regional safety and material regulations.

How should buyers conduct factory audits?

Request facility videos demonstrating CNC grinding lines, heat treatment chambers, and quality inspection stations. Verify staff expertise in metallurgy and tool geometry. For high-volume partnerships, consider third-party inspection services to audit production capacity, inventory levels, and packaging procedures prior to contract signing.