Cocopeat Maker Machine Producer

About cocopeat maker machine producer

Where to Find Cocopeat Maker Machine Suppliers?

China remains the dominant hub for cocopeat processing machinery production, with key manufacturing clusters concentrated in Henan Province. This region hosts a high density of industrial equipment manufacturers specializing in agricultural and waste-to-resource technologies, including drying systems, compression units, and briquetting lines essential for cocopeat block and brick production. The concentration of vertically integrated suppliers enables streamlined component sourcing, reducing lead times and system integration costs.

These clusters benefit from established supply chains for critical subsystems such as hydraulic presses, mesh screens, and motorized conveyors. Proximity to raw material sources—particularly steel and casting facilities—allows for cost optimization, with localized production reducing unit costs by 15–25% compared to non-industrialized regions. Buyers gain access to flexible production models capable of fulfilling both small-scale turnkey lines and modular upgrades for existing plants. Typical delivery windows range from 20–45 days depending on customization level, with most suppliers offering containerized shipping compatible with global logistics networks.

How to Choose Cocopeat Maker Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Process Alignment

Confirm compatibility between machine design and intended feedstock. Cocopeat systems must handle high-moisture coconut pith (typically 60–70% water content) and integrate dewatering, drying, and compression stages. Verify equipment specifications for moisture reduction capacity (target: ≤25% post-processing), compression ratio (commonly 5:1 to 8:1 volume reduction), and output format (brick size standardization: 650g, 1kg, or custom).

Production Capacity and Infrastructure

Assess physical and operational scale through verifiable metrics:

- Minimum factory area exceeding 3,000m² to support full assembly lines

- In-house engineering teams responsible for system integration and automation

- Proven experience with turnkey installations, including drying tunnels and packing units

Cross-reference claimed capabilities with documented project histories and video audits of operational facilities.

Quality Assurance and Transaction Security

Prioritize suppliers adhering to international quality management standards. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates (≥95%) and response times under 5 hours indicate reliable internal processes. Utilize secure payment mechanisms such as escrow services, especially when engaging new suppliers. Request performance validation through third-party inspection reports or independent customer references, particularly for orders above $10,000.

What Are the Best Cocopeat Maker Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (Min Order) | Product Count |

|---|---|---|---|---|---|---|---|---|

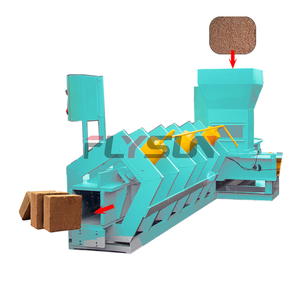

| Henan Flysun Machinery Manufacturing Co., Ltd. | Henan, CN | Drying Equipment, Waste Treatment, Briquette Machines | US $200,000+ | 100% | ≤3h | <15% | $9,100–$19,000 | 5 |

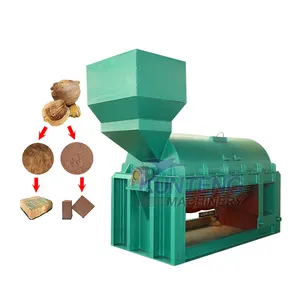

| Zhengzhou Longer Machinery Co., Ltd. | Henan, CN | Cocoa Processing, Food Lines, Nut Machinery | Not specified | 100% | ≤2h | Not available | $13,799–$44,999 | 4 |

| Henan Kunteng Machinery Manufacturing Co., Ltd. | Henan, CN | Custom Hydraulic Briquetting Systems | US $100,000+ | 100% | ≤5h | <15% | $2,896–$18,000 | 4 |

| Henan Sunrise Machinery Co., Limited | Henan, CN | Coir Pith Processing, Customization Options | US $260,000+ | 100% | ≤4h | 40% | $1,800–$28,000 | 5 |

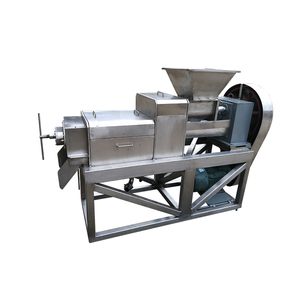

| Jingjiang Elite Food Machinery Co., Ltd. | Jiangsu, CN | Coconut Milk & Water Processing Lines | Not specified | 100% | ≤3h | Not available | $2,850 | 5 |

Performance Analysis

Henan-based manufacturers dominate the cocopeat machinery segment, demonstrating strong process specialization and export readiness. Henan Flysun and Henan Kunteng offer competitive pricing and customization options for compression and dewatering systems, with Flysun providing mid-range solutions starting at $9,100. Henan Sunrise stands out with a 40% reorder rate—the highest among listed suppliers—indicating strong customer satisfaction despite broader product diversification.

Zhengzhou Longer targets higher-end food processing applications but lists equipment relevant to cocoa and coir processing, suggesting potential crossover capability. Jingjiang Elite focuses on liquid coconut processing rather than solid pith, making it less suitable for core cocopeat production despite surface keyword alignment. Buyers should verify actual machine applicability, as some listings appear categorized under overlapping agricultural processing keywords.

FAQs

How to verify cocopeat maker machine supplier reliability?

Evaluate suppliers based on verifiable metrics: on-time delivery performance (target ≥95%), response time consistency (ideally ≤5 hours), and revenue scale as an indicator of transaction volume. Request facility videos or virtual audits to confirm production infrastructure. Validate machine functionality through test reports or client case studies, especially for moisture extraction efficiency and brick density output.

What is the typical minimum order quantity and pricing?

Standard MOQ is 1 set across all major suppliers. Pricing varies significantly based on automation level and throughput: basic dewatering presses start around $2,800–$3,500, while complete cocopeat brick production lines range from $9,000 to $28,000. Fully automated, high-capacity systems exceed $40,000. Cost differentials reflect drying method (rotary vs. solar-assisted), compression force (hydraulic vs. mechanical), and control system sophistication.

Do suppliers offer customization options?

Yes, multiple suppliers explicitly list customization capabilities, including hydraulic pressure adjustment, color coding, logo branding, packaging formats, and output size modification. Henan Kunteng and Henan Sunrise emphasize configurable briquetting parameters, allowing adaptation to regional market preferences for cocopeat brick dimensions and moisture content.

Can cocopeat machines be shipped internationally?

All listed suppliers have international transaction experience, evidenced by multilingual product pages and U.S. dollar pricing. Most support FOB terms, with primary ports in Qingdao, Shanghai, and Ningbo. Full container loads (20ft or 40ft) are standard for machinery shipments. Confirm whether disassembly, crating, and export documentation are included in quoted prices.

What are common lead times and sampling policies?

Lead times typically range from 20 to 35 days after deposit confirmation. Sample units are rarely offered due to equipment size and cost; instead, suppliers may provide video demonstrations or accept third-party inspections pre-shipment. Prototype builds for customized configurations require 4–6 weeks, depending on design complexity.