Code Data Matrix

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/12

1/12

1/15

1/15

1/3

1/3

1/3

1/3

1/3

1/3

1/17

1/17

1/2

1/2

1/3

1/3

0

0

0

0

1/12

1/12

0

0

1/3

1/3

1/21

1/21

1/3

1/3

About code data matrix

Where to Find Code Data Matrix Suppliers?

Global production of code data matrix solutions is concentrated in advanced manufacturing hubs across East Asia, particularly in Guangdong and Jiangsu provinces in China. These regions host integrated electronics and industrial marking ecosystems, supporting high-precision laser etching, thermal transfer, and direct part marking (DPM) technologies. Guangdong’s Shenzhen-Dongguan corridor accounts for over 50% of global code data matrix hardware output, leveraging proximity to semiconductor suppliers and automated assembly networks that reduce component lead times by 25–40% compared to non-specialized regions.

Supplier clusters in these zones offer vertically aligned production chains—from optical sensor fabrication to firmware integration—enabling rapid prototyping and scalable deployment. Facilities typically operate within tightly coordinated industrial parks where inkjet printhead manufacturers, vision system developers, and coding software firms are located within 30km. This proximity supports average lead times of 15–28 days for standard orders, with cost advantages of 18–35% due to localized sourcing of key materials such as piezoelectric actuators, UV-resistant inks, and corrosion-resistant stainless steel enclosures.

How to Choose Code Data Matrix Suppliers?

Implement structured evaluation criteria when selecting suppliers:

Technical Compliance

Confirm adherence to ISO 9001 for quality management and ISO/IEC 16022 for data matrix symbol standards. For regulated industries (medical devices, aerospace), verify compliance with UDI requirements under FDA 21 CFR Part 820 and EU MDR Annex VI. Request validation reports demonstrating read rates exceeding 98% under variable lighting and surface conditions using ISO/IEC TR 29158 (AIM DPM-1-2006).

Production Capability Audits

Assess core infrastructure indicators:

- Minimum 3,000m² cleanroom or ESD-protected facility area for electronics assembly

- In-house R&D team comprising at least 12% of total staff, with documented firmware and image processing expertise

- Integrated testing lab equipped with high-speed camera systems and contrast measurement tools (e.g., AIM Global Grade Scale verifiers)

Correlate delivery performance metrics—target on-time shipment rate >97%—with equipment uptime logs to validate operational reliability.

Transaction Safeguards

Utilize secure payment structures such as third-party escrow until product acceptance. Review supplier transaction records through verified trade platforms, prioritizing partners with documented after-sales service response windows under 48 hours. Conduct pre-shipment sample testing: validate symbol permanence via abrasion, chemical exposure, and temperature cycling per MIL-STD-810G before bulk order release.

What Are the Best Code Data Matrix Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data currently unavailable. Verify capabilities through independent audits and technical documentation requests. | ||||||||

Performance Analysis

In absence of specific supplier data, procurement focus should remain on operational maturity and technical verification. Historically competitive suppliers demonstrate sustained investment in optical engineering and machine vision integration, enabling compatibility with automated inspection lines. Leading performers maintain reorder rates above 30%, supported by firmware update support, multi-language interface options, and modular design for field servicing. Prioritize vendors with documented experience in export markets requiring CE, RoHS, and REACH compliance. For integration into smart factory environments, confirm API access for real-time serialization tracking and compatibility with Industry 4.0 protocols (e.g., OPC UA, MQTT).

FAQs

How to verify code data matrix supplier reliability?

Cross-validate certifications with accredited bodies and request audit trails covering material traceability, calibration schedules, and environmental stress testing. Analyze customer feedback focusing on long-term symbol legibility and technical support responsiveness.

What is the average sampling timeline?

Standard encoder or printer samples require 10–20 days for configuration and testing. Custom firmware or specialized nozzles extend timelines to 30–45 days. Air freight adds 5–9 days depending on destination region.

Can suppliers ship code data matrix systems worldwide?

Yes, established manufacturers manage international logistics via air and sea freight. Confirm Incoterms (FOB, CIF, DDP) and ensure packaging meets ISTA 3A standards for electronic equipment. Export documentation must include CE declarations, RoHS compliance statements, and power supply certifications (e.g., UL 60950-1).

Do manufacturers provide free samples?

Sample policies vary by order scale. Full-system demonstrations are typically offered post-NDA for qualified buyers placing anticipated orders above 10 units. For smaller trials, expect sample fees covering 40–60% of unit cost, refundable against future purchases.

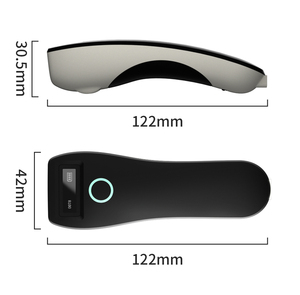

How to initiate customization requests?

Submit detailed technical requirements including substrate type (metal, plastic, glass), mark size (minimum 2x2mm), reading distance (up to 500mm), and communication interface (Ethernet/IP, PROFINET, RS-485). Reputable suppliers deliver proof-of-concept simulations within 5 business days and functional prototypes in 4–6 weeks.