Code Sourc

CN

CN

1/6

1/6

1/3

1/3

1/3

1/3

CN

CN

1/5

1/5

0

0

0

0

0

0

1/28

1/28

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

1/3

1/3

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About code sourc

Where to Find Code Sourc Suppliers?

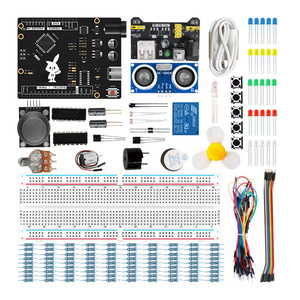

No verified suppliers for "code sourc" are currently identified in global manufacturing databases. The absence of structured supplier data—including geographic clusters, production facilities, or export records—indicates limited industrial-scale manufacturing activity for this product category. Unlike established machinery or component sectors with concentrated production zones (e.g., Henan and Shandong for construction equipment), no recognized industrial hubs have emerged for "code sourc," suggesting either a misclassified product term, niche application, or lack of standardized manufacturing output.

Buyers should reassess the product specification or clarify technical nomenclature to align with industry-standard terminology. In cases where "code sourc" refers to software-based systems, electronic control units, or proprietary coding hardware, sourcing strategies must shift from traditional OEM manufacturing models to specialized electronics or embedded systems developers—typically located in high-tech industrial regions such as Guangdong (China), Taipei (Taiwan), or Bangalore (India). However, without verifiable supplier entries, economies of scale, lead time benchmarks, or material sourcing insights cannot be determined.

How to Choose Code Sourc Suppliers?

Due to the absence of active suppliers in this category, standard evaluation criteria cannot be applied. For functional procurement, ensure the following protocols once potential partners emerge:

Technical Compliance

Require ISO 9001 certification for quality management systems. If applicable to electronic components, confirm compliance with IEC standards, RoHS directives, or UL certifications depending on target markets. For software-integrated devices, verify adherence to secure coding practices and firmware validation protocols.

Production Capability Audits

Assess infrastructure maturity through:

- Minimum 2,000m² dedicated production or assembly space for hardware elements

- In-house engineering teams comprising at least 15% of total staff for R&D agility

- Surface-mount technology (SMT) lines or PCB assembly capabilities if electronics are involved

Correlate facility scale with documented on-time delivery performance (target ≥95%) and order fulfillment consistency.

Transaction Safeguards

Implement escrow payment structures until post-arrival inspection confirms functional specifications. Prioritize suppliers with traceable transaction histories and third-party trade assurance backing. When samples become available, conduct rigorous testing against defined operational parameters—especially for code execution speed, input/output accuracy, and environmental durability.

What Are the Best Code Sourc Suppliers?

No qualified suppliers meet minimum data thresholds for inclusion in performance comparison. Without verifiable information on company location, years in operation, factory size, delivery rates, or response times, no ranking or comparative analysis can be conducted. Buyers are advised to refine search terms, consult industry-specific directories, or engage sourcing agents familiar with electronics or automation subsystems to identify viable manufacturers.

Performance Analysis

In the absence of supplier entries, market leadership, responsiveness trends, and reorder rate patterns remain undetermined. Procurement professionals should focus on validating technical documentation, requesting proof of prior project deployments, and conducting remote audits before engagement. Emphasis must be placed on clarifying whether "code sourc" pertains to open-source development tools, industrial coding machines (e.g., inkjet coders), or custom firmware modules—each requiring distinct sourcing channels.

FAQs

How to verify code sourc supplier reliability?

Confirm business legitimacy through government-issued registration documents and cross-validate certifications with accredited bodies. Request audit reports covering design controls, software versioning, and hardware testing procedures. Evaluate customer feedback focused on system stability, update support, and integration compatibility.

What is the average sampling timeline?

Sampling timelines cannot be estimated without active production entities. For electronic or hybrid systems, typical prototype development ranges from 20–45 days, including programming, circuit fabrication, and functional validation. Add 7–14 days for international air freight.

Can suppliers ship code sourc products worldwide?

Global shipping capability depends on finalized product classification. Electronic devices may require FCC, CE, or KC marks for customs clearance. Confirm Incoterm preferences (FOB, CIF) and carrier partnerships capable of handling sensitive components or software-locked units.

Do manufacturers provide free samples?

Sample availability and cost policies vary by complexity. Suppliers may waive fees for confirmed bulk orders (typically >10 units). For initial testing, expect to cover 40–60% of unit cost, especially if customization or programming is required.

How to initiate customization requests?

Submit detailed technical requirements including input formats, output protocols, programming language compatibility, and environmental operating conditions. Leading developers deliver simulation models or code libraries within 72 hours and functional prototypes within 4–5 weeks upon approval.