Coding Pin

Top sponsor listing

Top sponsor listing

0

0

1/32

1/32

0

0

1/3

1/3

1/1

1/1

0

0

1/67

1/67

1/1

1/1

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/32

1/32

1/5

1/5

1/3

1/3

1/3

1/3

1/4

1/4

0

0

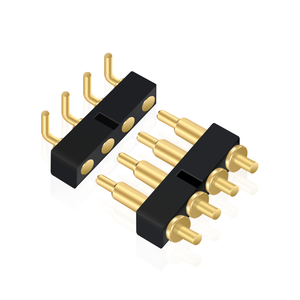

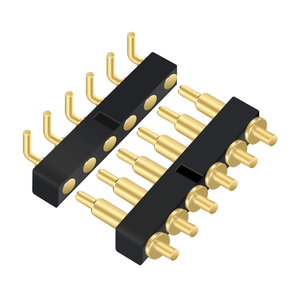

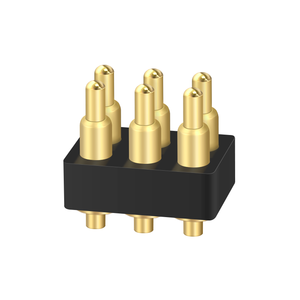

About coding pin

Where to Find Coding Pin Suppliers?

No verified suppliers for coding pins are currently available in the dataset. This absence suggests limited industrial specialization or underdeveloped manufacturing clusters dedicated exclusively to coding pin production. Unlike mature equipment categories with concentrated regional hubs, coding pin sourcing may rely on niche electronics component manufacturers or custom machining workshops operating within broader electromechanical supply chains.

In markets where such components are produced, they are typically integrated into larger identification, tracking, or access control systems. Production would require precision machining capabilities, clean-room assembly environments (for contact point integrity), and compliance with electronic component standards. However, without active supplier data, economies of scale, lead time benchmarks, and cost advantages associated with established clusters cannot be determined.

How to Choose Coding Pin Suppliers?

Due to the lack of identifiable suppliers, procurement strategies must focus on capability-based qualification from adjacent manufacturing sectors:

Technical Compliance

Prioritize suppliers certified under ISO 9001 for quality management and ISO/IEC 80079-34 for explosive atmospheres if applicable. For integration into electronic security systems, verify compatibility with IEC 60730 (automatic electrical controls) or UL 2610 for access control equipment. Request material certifications for pin conductors—typically beryllium copper or phosphor bronze with gold or nickel plating—to ensure signal reliability and corrosion resistance.

Production Capability Audits

Assess potential manufacturers based on:

- Minimum 2,000m² facility with ESD-safe production zones

- In-house CNC micro-machining and stamping capabilities for pin fabrication

- Automated optical inspection (AOI) systems for contact alignment verification

Confirm traceability protocols and batch testing records for electrical continuity and insertion force durability (per IEC 60512-5).

Transaction Safeguards

Utilize third-party inspection services prior to shipment, particularly for first-time engagements. Require sample validation against IPC-6012 or MIL-STD-883H test procedures for high-reliability applications. Use secure payment terms with milestone releases tied to production stages and independent lab results.

What Are the Best Coding Pin Suppliers?

No supplier data is available for coding pin manufacturers. The absence of operational entities in the dataset prevents performance comparison, delivery metrics analysis, or responsiveness benchmarking. Buyers should proactively engage general-purpose connector, terminal, or smart card component producers who may offer coding pins as part of a broader product portfolio.

Performance Analysis

Without listed suppliers, no market leaders can be identified. Procurement efforts should shift toward identifying companies with documented experience in precision contact manufacturing, low-current signal transmission, and miniaturized component assembly. Target firms with export histories to North America or EU markets, indicating adherence to RoHS, REACH, and conflict minerals reporting requirements.

FAQs

How to verify coding pin supplier reliability?

Conduct remote audits via video walkthroughs of production lines and quality labs. Request full material disclosure (FMD) and SGS/RoHS compliance reports. Validate past shipments through freight forwarder references or customs export records.

What is the average sampling timeline?

For qualified manufacturers, expect 10–18 days for prototype samples of standard configurations. Custom geometries or specialized plating may extend development to 25–30 days. Add 5–9 days for international express delivery.

Can suppliers ship coding pins worldwide?

Yes, but only through manufacturers experienced in exporting electronic components. Confirm packaging compliance with ESD protection standards (ANSI/ESD S541) and proper HS code classification (typically 8536.90) for smooth customs processing.

Do manufacturers provide free samples?

Free samples are uncommon for precision components. Most suppliers charge a nominal fee (USD 20–50) to cover setup and handling, refundable against initial orders exceeding 1,000 units.

How to initiate customization requests?

Submit detailed mechanical drawings specifying pin diameter, length, tip profile, spring force, and mating cycle requirements (up to 50,000 insertions). Include environmental conditions (temperature range, humidity, exposure to contaminants) and desired packaging format (tape & reel, bulk, tube).