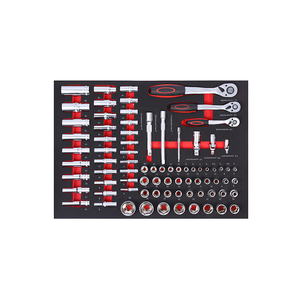

Combination Tools Set Producer

About combination tools set producer

Where to Find Combination Tools Set Producers?

China remains the global epicenter for combination tools set manufacturing, with key production clusters concentrated in Zhejiang, Guangdong, and Hebei provinces. These regions host vertically integrated supply chains that streamline raw material sourcing—primarily chrome vanadium steel (CRV) and S2 alloy—and precision machining processes such as drop forging, heat treatment, and surface coating. Yongkang in Zhejiang alone accounts for over 60% of China’s hand tool output, supported by a mature ecosystem of component suppliers, packaging vendors, and logistics networks within a 50-kilometer radius.

Suppliers leverage economies of scale to offer competitive pricing and flexible order volumes, with average lead times ranging from 20–45 days depending on customization complexity. Bulk production capabilities range from 10,000 to over 100,000 sets per month across verified manufacturers. The integration of OEM/ODM services enables buyers to specify materials, packaging, branding, and tool configurations, including ratchet mechanisms, bit types, and case designs. This infrastructure supports both high-volume retail contracts and niche B2B procurement needs.

How to Choose Combination Tools Set Producers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Assurance Standards

Verify compliance with international quality benchmarks such as ISO 9001 for quality management systems. Tool performance should align with DIN or ANSI standards for torque tolerance, hardness (typically HRC 58–62 for CRV components), and durability. Request test reports for critical attributes like corrosion resistance (via salt spray testing) and fatigue life under repeated loading.

Production Capacity Verification

Assess infrastructure maturity through objective indicators:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house forging, CNC machining, and heat treatment lines to ensure process control

- Dedicated quality inspection stations with coordinate measuring machines (CMM) or optical comparators

Cross-reference on-time delivery rates (target ≥95%) and response times (ideally ≤2 hours) as proxies for operational reliability.

Customization & Transaction Security

Confirm availability of OEM/ODM services including laser engraving, color-coded cases, and branded packaging. Prioritize suppliers offering third-party transaction protection and clear dispute resolution protocols. Pre-shipment inspections via third-party auditors (e.g., SGS, BV) are recommended for first-time orders. Sample validation is critical—test functionality, fitment, and material integrity before scaling to full production.

What Are the Leading Combination Tools Set Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Customization |

|---|---|---|---|---|---|---|---|---|

| Yongkang Youren Trading Co., Ltd. | Zhejiang, CN | Tool Sets, Tool Cabinets, Salon Trolleys | US $200,000+ | 98% | ≤2h | <15% | 1–10 sets | Not specified |

| Shenzhen Yincheng Technology Co., Ltd. | Guangdong, CN | Tool Sets, Pliers, Power Drills | US $40,000+ | 100% | ≤1h | <15% | 2 sets | Not specified |

| Hangzhou Lin'an Faqiang Hardware Tools Co., Ltd. | Zhejiang, CN | Hand Tools, Combination Sets | US $9,000+ | 100% | ≤3h | <15% | 10–100 sets | Color, size, logo, packaging |

| Shenzhen Jiashida Hardware Manufacturing Co., Ltd. | Guangdong, CN | Power Tools, Tool Sets, Lawn Mowers | US $200,000+ | 95% | ≤4h | <15% | 1–48 sets | Not specified |

| Tianjin Ruixin Tools & Hardware Co., Ltd. | Tianjin, CN | Wrenches, Tool Sets, Drill Bits | US $20,000+ | 100% | ≤2h | <15% | 1–100 sets | Not specified |

Performance Analysis

Suppliers like Shenzhen Yincheng and Tianjin Ruixin demonstrate exceptional responsiveness with 100% on-time delivery and sub-2-hour average response times, making them suitable for time-sensitive procurement cycles. Hangzhou Lin’an Faqiang stands out for its explicit support of full customization—including material, color, branding, and packaging—positioning it as an ideal partner for private-label development. While reorder rates across all listed suppliers remain below 15%, this may reflect dominance in B2B wholesale rather than end-user retail channels where repeat purchases are more common. Companies with higher online revenue (e.g., Yongkang Youren, Shenzhen Jiashida at US $200,000+) likely possess stronger export logistics frameworks and multi-market distribution experience.

FAQs

How to verify a combination tools set manufacturer's reliability?

Cross-check ISO certification status with accredited bodies. Request facility videos highlighting production lines and quality control checkpoints. Analyze transaction history for consistent fulfillment patterns and review customer feedback focused on product consistency and communication efficiency.

What is the typical MOQ for combination tools sets?

MOQs vary from 1 set for sample testing to 10–100 sets for bulk pricing. High-volume producers often require minimum batch sizes of 500+ units for customized toolkits. Negotiation leverage increases significantly at order volumes exceeding 1,000 units.

Do suppliers offer OEM/ODM services?

Yes, select manufacturers provide comprehensive OEM/ODM capabilities, including custom tool selection, case design, branding (laser engraving or stickers), and packaging. Hangzhou Lin’an Faqiang explicitly lists color, size, logo, and graphic customization options, indicating established design-to-delivery workflows.

What materials are commonly used in combination tool sets?

Primary materials include chrome vanadium steel (CRV) for wrenches and sockets due to its high tensile strength and fatigue resistance, and S2 steel for precision screwdriver bits. Cases are typically molded from ABS plastic or durable PP composites with EVA foam inserts for tool retention.

How long does sampling take?

Standard samples are typically produced within 7–15 days. Customized prototypes requiring new molds or tooling may take 20–30 days. Air shipping adds 5–10 days for international delivery. Buyers should budget 3–4 weeks from request to physical evaluation for optimal planning.