Components Of Computer Network

0

0

1/10

1/10

1/17

1/17

1/2

1/2

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/31

1/31

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

0

0

0

0

1/3

1/3

About components of computer network

Where to Find Components of Computer Network Suppliers?

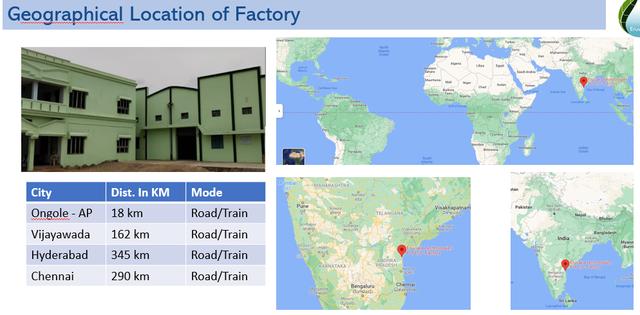

Global manufacturing of computer network components is highly concentrated in East Asia, with China accounting for over 70% of production capacity. Key industrial hubs in Guangdong, Jiangsu, and Zhejiang provinces host vertically integrated supply chains that specialize in PCB assembly, connector fabrication, and data transmission hardware. Dongguan and Shenzhen alone support more than 12,000 electronics component manufacturers, leveraging proximity to semiconductor foundries and surface-mount technology (SMT) facilities.

These regions benefit from mature ecosystems where raw material sourcing, precision molding, and automated testing occur within tightly coordinated networks. Suppliers in these clusters achieve lead times of 20–35 days for standard orders due to localized access to copper alloys, FR-4 substrates, and RJ45 modules. Cost efficiencies range from 25–40% compared to North American or European producers, driven by economies of scale, automation rates exceeding 85%, and streamlined logistics via Hong Kong and Shanghai ports. Buyers gain flexibility in both high-volume procurement and low-MOQ prototyping runs.

How to Choose Components of Computer Network Suppliers?

Implement the following verification protocols to ensure supplier reliability:

Quality & Compliance Standards

Confirm adherence to ISO 9001 for quality management and ISO/IEC 27001 for information security—critical for components handling data traffic. For EU markets, validate RoHS and REACH compliance to avoid customs delays. Ethernet-related parts (e.g., switches, NICs, cables) should meet IEEE 802.3 standards; wireless modules must comply with FCC Part 15 and CE RED directives.

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum 3,000m² cleanroom or ESD-safe facility area

- In-house SMT lines with placement accuracy ≤±0.03mm

- Automated optical inspection (AOI) and burn-in testing stations

Verify monthly output capacity against order volume—suppliers handling >500k units/month typically maintain dual-source component inventories to mitigate supply chain disruptions.

Procurement Safeguards

Utilize third-party inspection services (e.g., SGS, TÜV) for pre-shipment audits on第一批货 (first batch). Prioritize suppliers offering sample validation under real-world load conditions—test packet loss rate, insertion loss (for fiber optics), and crosstalk performance. Escrow payment terms reduce financial risk during initial engagements, particularly for customized PCBs or proprietary transceivers.

What Are the Best Components of Computer Network Suppliers?

No verified supplier data available at this time.

Performance Analysis

In absence of specific supplier profiles, procurement focus should remain on operational transparency and technical documentation. Established players in the sector typically demonstrate consistent on-time delivery (>97%), multi-language engineering support, and traceable component lot numbering. Newer entrants may offer competitive pricing but require rigorous qualification through factory audits and sample benchmarking. When evaluating potential partners, confirm export experience to regulated markets (e.g., U.S., Germany, Japan) as an indicator of compliance maturity.

FAQs

How to verify network component supplier reliability?

Cross-reference certifications with accredited bodies and request test reports for signal integrity, EMI/EMC performance, and thermal cycling durability. Analyze customer feedback related to failure rates, warranty claims, and firmware update support for smart components like managed switches.

What is the typical sampling timeline?

Standard passive components (e.g., Ethernet jacks, patch panels) require 7–14 days for sample production. Active devices (e.g., PoE injectors, media converters) take 15–25 days due to firmware integration and functional testing. Air freight adds 5–10 days for international delivery.

Can suppliers ship network components worldwide?

Yes, most manufacturers support global distribution via air or sea freight. Confirm Incoterms (FOB, CIF, DDP) early in negotiation. Suppliers experienced in exporting to Tier-1 OEMs often have bonded warehouses and can manage import clearance documentation for key markets.

Do manufacturers provide free samples?

Free samples are commonly offered for passive components when followed by volume orders (typically MOQ ≥1,000 units). For active or custom-designed units, expect to pay 50–100% of unit cost, which may be credited toward first production run.

How to initiate customization requests?

Submit detailed specifications including pin configuration, impedance requirements (e.g., 100Ω ±10%), shielding type, operating temperature (-40°C to +85°C), and compliance targets. Reputable suppliers will return Gerber files, 3D models, and prototype units within 2–4 weeks for approval.