Computer Chip Maker

Top sponsor listing

Top sponsor listing

About computer chip maker

Where to Find Computer Chip Maker Suppliers?

Global sourcing for computer chip makers is increasingly concentrated in electronics manufacturing hubs, particularly within southern China, where Shenzhen serves as a core node in the semiconductor supply chain. This region hosts a dense network of specialized recyclers, component testers, and packaging facilities that support both new and reclaimed silicon procurement. The ecosystem enables rapid access to CPU scrap materials with high gold content, ceramic substrates, and functional microprocessors from decommissioned systems.

Suppliers in this space often operate at the intersection of e-waste recovery and industrial electronics distribution, leveraging cost advantages from post-consumer material streams. These operations benefit from established logistics channels for bulk shipments of processed scrap—typically categorized by grade, weight, and metal yield. Buyers can access consistent volumes of reusable chips or raw materials suitable for refining, with minimal processing overhead due to pre-sorted categorization and standardized packaging.

How to Choose Computer Chip Maker Suppliers?

Selecting reliable partners requires rigorous evaluation across three critical dimensions:

Material Quality & Traceability

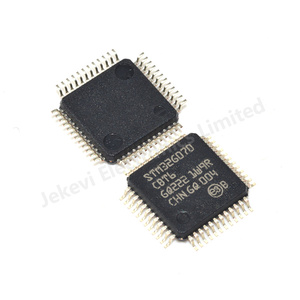

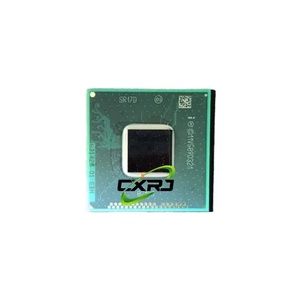

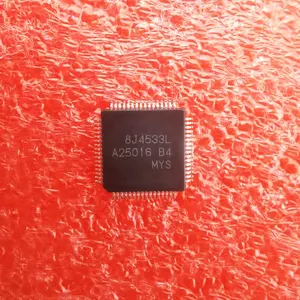

Verify the origin and classification of chip scrap (e.g., ceramic vs. organic substrate, Intel/AMD architecture). High-grade materials should be free of physical damage, moisture ingress, or excessive oxidation. Request batch-specific photos and, when possible, elemental analysis reports detailing precious metal content (gold, palladium) per kilogram. Reputable suppliers provide clear labeling of processor types (Pentium, Core i-series, etc.) and specify whether units are tested, functional, or intended solely for recovery purposes.

Production and Handling Capacity

Assess operational scale through minimum order quantities (MOQs), which range from 10 kg for refined samples to 50+ metric tons for industrial buyers. Key indicators include dedicated storage infrastructure for electronic scrap, use of non-corrosive handling methods, and segregation protocols to prevent cross-contamination. Prioritize suppliers capable of fulfilling large-volume orders consistently, supported by verifiable shipment records and inventory turnover data.

Transaction Reliability Metrics

Focus on response time, delivery consistency, and transaction transparency:

- Target suppliers with response times ≤2 hours for timely communication

- Prioritize those reporting 100% on-time delivery rates where available

- Confirm declared value accuracy and compliance with customs documentation standards

Cross-reference online revenue indicators and reorder rates if accessible to gauge customer retention and service reliability.

What Are the Best Computer Chip Maker Suppliers?

| Company Name | Main Products | Product Listings | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Zhida Shunfa Electronics Co., Ltd. | Other ICs, Microcontrollers, FPGAs, Discrete Modules | 28,146+ | Not specified | Not disclosed | 100% | ≤2h | 30% | Yes (labeling, packaging, refurbished grading) |

| ABA FRIO LTDA | CPU Scrap (Ceramic/Gold Recovery) | 5 | 1,000–7,000 kg | $3.55–12/kg | Not reported | ≤5h | Not reported | No customization noted |

| Solution Beta | CPU Scrap, Gold Pins, Processors | 5 | 100 kg – 50 tons | $5–150/kg | Not reported | ≤2h | Not reported | Limited to bulk form factors |

| BV Reno Trade | Ceramic CPU Scrap, Used Motherboards | 5 | 20 tons (standard) | $380/ton | Not reported | ≤9h | Not reported | Standardized lots only |

| Lehnen Maschinen GmbH | Refurbished CPUs, Gold Recovery Chips | 5 | 10 kg (minimum) | $7–780/kg | Not reported | ≤2h | Not reported | Grading and cleaning options |

Performance Analysis

Shenzhen Zhida Shunfa stands out with verified 100% on-time delivery, sub-2-hour response times, and a 30% reorder rate, indicating strong service consistency and buyer trust. Its extensive product catalog suggests integration into active semiconductor distribution networks. In contrast, European-based Lehnen Maschinen GmbH offers lower MOQs ideal for sampling or small-scale refining, though pricing varies significantly based on purity and processing level. Latin American and African intermediaries like ABA FRIO LTDA and Solution Beta focus on high-volume scrap exports but lack performance metrics, increasing due diligence requirements.

FAQs

How to verify computer chip maker supplier reliability?

Evaluate transaction history through documented delivery performance, response benchmarks, and customer feedback where available. Request references for past shipments and validate material descriptions against sample inspections. For high-value contracts, consider third-party audits of inventory management practices and export compliance procedures.

What is the typical lead time for computer chip scrap orders?

Standard lead times range from 7–15 days after payment confirmation, depending on order size and destination. Small batches (under 1 ton) may ship within one week; full-container loads (20+ tons) require additional preparation and customs coordination, extending timelines to 20 days.

Can suppliers provide certified material composition reports?

Some advanced processors offer basic metal yield estimates upon request, though formal certification (e.g., XRF analysis) is rarely included standard. Buyers should negotiate testing add-ons for orders exceeding 5 metric tons to ensure expected recovery returns.

Do suppliers support international shipping and customs clearance?

Yes, most exporters handle global freight via sea or air, offering FOB or CIF terms. Confirm HS code classification (typically 8548.10 for electronic scrap) and ensure proper declaration of contents to avoid delays. Some suppliers assist with import documentation for key markets.

Are samples available before placing bulk orders?

Sample availability varies. Certain suppliers offer small test batches (1–10 kg) at premium rates to evaluate material quality. Expect to cover full shipping costs and pay per-unit prices above wholesale rates. Sample policies should be confirmed prior to engagement.