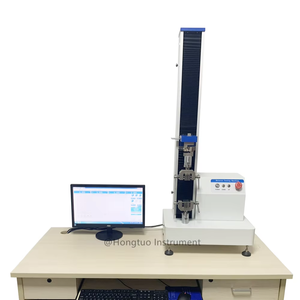

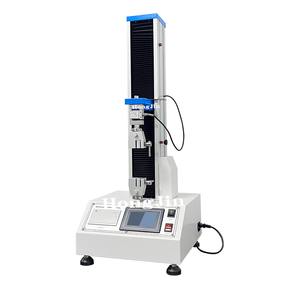

Computer Control Universal Tensile Testing Machine Company

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/1

1/1

1/3

1/3

1/2

1/2

1/3

1/3

About computer control universal tensile testing machine company

Where to Find Computer Control Universal Tensile Testing Machine Suppliers?

China remains the global hub for manufacturing computer control universal tensile testing machines, with key production clusters in Shandong and Guangdong provinces. Jinan, the capital of Shandong, has emerged as a specialized center for precision testing equipment, hosting vertically integrated manufacturers that produce load frames, servo-hydraulic systems, and software-controlled data acquisition units in-house. This regional concentration enables streamlined component sourcing and reduces lead times by up to 25% compared to decentralized production models.

Suppliers in Dongguan (Guangdong) and Jinan (Shandong) benefit from mature industrial ecosystems where CNC machining, structural steel fabrication, and electronic control system integration are available within localized supply networks. These clusters support rapid prototyping and scalable production, with average factory areas exceeding 5,000m² and monthly output capacities ranging from 50 to 200 units depending on model complexity. Buyers gain access to flexible MOQs—often as low as one set—and competitive pricing driven by economies of scale and optimized logistics infrastructure.

How to Choose Computer Control Universal Tensile Testing Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Standards

Confirm adherence to international testing standards such as ASTM E8, ISO 6892-1, and GB/T 228.1. Demand documented compliance with CE marking for European market access and verify integration of calibrated load cells (accuracy class ≤ 0.5%) and real-time strain measurement systems. Software compatibility with Windows-based control platforms and data export functionality (e.g., CSV, PDF reporting) should be validated prior to procurement.

Production Capability Verification

Assess core manufacturing competencies through the following indicators:

- Minimum 3,000m² dedicated production space with separate zones for welding, machining, assembly, and calibration

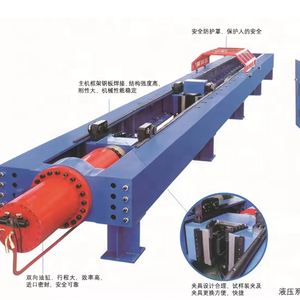

- In-house engineering teams capable of customizing force capacity (ranging from 2kN to 2000kN), test space configurations, and environmental chamber integration

- On-site quality assurance labs equipped with reference standards for force, displacement, and strain verification

Cross-reference declared capabilities with on-time delivery performance; suppliers maintaining ≥90% punctuality demonstrate reliable workflow management.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial disbursement with shipment milestones. Prioritize suppliers with transparent reorder rates and response times under 4 hours, which indicate strong customer service infrastructure. Pre-shipment inspection protocols—including video audits of final calibration tests—are recommended to verify machine accuracy before dispatch.

What Are the Best Computer Control Universal Tensile Testing Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Tensile Testers (Listings) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Jinan Chenda Testing Machine Manufacturing Co., Ltd. | Jinan, CN | Testing Equipment (157) | 37 | 100% | ≤3h | US $20,000+ | 33% |

| Dongguan Haoen Automation Equipment Co., Ltd. | Dongguan, CN | Testing Equipment (171) | 18 | 100% | ≤2h | US $40,000+ | <15% |

| Jinan Zhongchuang Industry Test Systems Co., Ltd. | Jinan, CN | Testing Equipment (484) | 149 | 90% | ≤2h | US $40,000+ | <15% |

| Dongguan Best Instrument Technology Co., Ltd. | Dongguan, CN | Testing Equipment (181) | 45 | 50% | ≤3h | US $10,000+ | <15% |

| Guangdong Hongtuo Instrument Technology Co., Ltd. | Guangdong, CN | Testing Equipment (600) | 10 | 100% | ≤4h | US $40,000+ | 30% |

Performance Analysis

Jinan Chenda stands out for high-volume specialization, offering models up to 2000kN (WAW-2000E) with hydraulic servo control, reflecting deep expertise in heavy-duty mechanical testing. Despite a moderate reorder rate, its 100% on-time delivery record supports reliability for large-scale procurement. Dongguan Haoen and Jinan Zhongchuang provide broader product portfolios, with Zhongchuang listing 149 tensile tester variants—indicating strong R&D agility and customization depth. Guangdong Hongtuo demonstrates consistent fulfillment (100% on-time) and a 30% reorder rate, suggesting effective post-sale support despite fewer dedicated listings. Notably, Dongguan Best lags in delivery consistency (50%), signaling potential operational bottlenecks despite competitive pricing.

FAQs

What is the typical price range for computer control universal tensile testing machines?

Prices vary significantly based on load capacity and control system type. Entry-level single-column electronic models (e.g., 2–50kN) range from $1,299 to $4,000. Mid-range double-column systems (100–500kN) typically cost $6,000–$15,000. High-capacity servo-hydraulic units (600–2000kN) command $9,000–$32,000, reflecting advanced actuation and structural reinforcement.

What are common MOQ and lead time expectations?

Most suppliers offer MOQs of 1 set, supporting pilot procurement and small lab setups. Standard lead times range from 15 to 30 days after order confirmation. Custom configurations involving non-standard grips, extensometers, or environmental chambers may extend production to 45 days.

Can suppliers customize software and data output features?

Yes, leading suppliers provide customizable test software with programmable test sequences, multi-language interfaces, and automated report generation. Integration with LIMS (Laboratory Information Management Systems) is available upon request, though may require additional development fees and extended timelines.

Do manufacturers offer calibration certificates?

Reputable suppliers issue出厂检验证书 (factory inspection certificates) with traceable load cell calibration. For accredited applications, third-party certification from bodies like SGS or TÜV can be arranged at extra cost. In-field recalibration services may also be offered for long-term maintenance contracts.

How to evaluate after-sales service capability?

Assess responsiveness (target ≤4h), availability of English-speaking technical support, and warranty terms (typically 12 months). Request references for overseas clients in your region to validate installation assistance, spare parts availability, and remote troubleshooting effectiveness.