Computer Control Universal Tensile Testing Machine Exporter

CN

CN

About computer control universal tensile testing machine exporter

Where to Find Computer Control Universal Tensile Testing Machine Exporters?

China remains the global hub for precision testing equipment manufacturing, with key supplier clusters concentrated in Guangdong and Shandong provinces. These regions host vertically integrated industrial ecosystems specializing in material testing instrumentation, supported by mature supply chains for servo motors, load cells, and control systems. Dongguan and Guangzhou in Guangdong province account for over 40% of China’s tensile testing machine exports, leveraging proximity to component manufacturers and Hong Kong’s logistics infrastructure for rapid international shipment.

Shandong-based suppliers, particularly around Jinan and Qingdao, focus on heavy-capacity electro-hydraulic UTM systems, benefiting from regional steel production and machining expertise. The concentration of R&D centers and calibration laboratories within these zones enables compliance with ASTM, ISO, and GB standards. Buyers gain access to streamlined production cycles, with average lead times ranging from 25–40 days for standard configurations. Localized sourcing reduces costs by 18–25% compared to European or North American manufacturers, while maintaining technical parity through widespread adoption of Class 1 accuracy per ISO 7500-1.

How to Choose Computer Control Universal Tensile Testing Machine Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

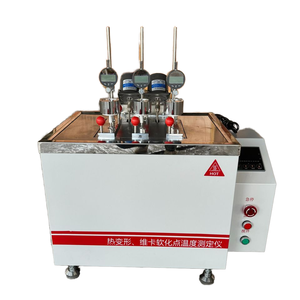

Technical Compliance & Calibration Standards

Verify adherence to international performance benchmarks such as ISO 7500-1 (static tension/compression tests) and ASTM E4. Demand certified calibration reports traceable to national metrology institutes. For export markets, CE marking is essential for EU customs clearance, while UL or CSA alignment supports North American deployments. Confirm software compatibility with Windows-based reporting platforms and data export formats (Excel, PDF, CSV).

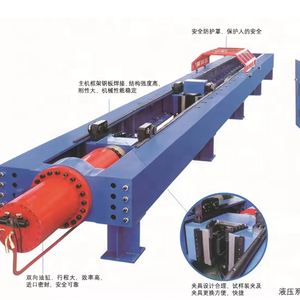

Production and Engineering Capacity

Assess core capabilities through the following indicators:

- Minimum factory area exceeding 3,000m² to support assembly, testing, and warehousing

- In-house engineering teams capable of customizing force ranges (1kN–3000kN), crosshead speeds, and test fixtures

- Integration of microcomputer control systems with real-time strain measurement and automatic data logging

Cross-reference online revenue metrics and reorder rates to validate market acceptance and post-sales reliability.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality management systems. On-time delivery rates above 90% and response times under 6 hours indicate operational discipline. Utilize secure payment mechanisms and request sample units for independent validation against ASTM D638 (plastics) or ASTM E8 (metals). Pre-shipment inspections should include verification of load cell accuracy, frame rigidity, and emergency stop functionality.

What Are the Leading Computer Control Universal Tensile Testing Machine Exporters?

| Company Name | Location | Verified Role | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Guangdong Liyi Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | Tensile, peel, compression testers; hydraulic UTM | US $790,000+ | 93% | ≤6h | 50% | Yes (color, size, logo, packaging) |

| Shandong Dekon Import Export Co., Ltd. | Shandong, CN | - | Electronic & electro-hydraulic UTMs, hardness testers | US $50,000+ | 100% | ≤2h | <15% | No |

| Dongguan Zhongli Instrument Technology Co., Ltd. | Guangdong, CN | Brand Holder | Benchtop, desktop, computerized tensile testers | US $440,000+ | 100% | ≤2h | 30% | Yes (material, size, software, packaging) |

| Dongguan Lixian Instrument Scientific Co., Ltd. | Guangdong, CN | Custom Manufacturer | Microcomputer-controlled UTMs, climate chambers | US $100,000+ | 87% | ≤4h | 16% | Yes (color, logo, packaging) |

| Guangdong Kejian Instrument Co., Ltd. | Guangdong, CN | - | Servo-controlled UTMs, rubber/plastic testers | US $10,000+ | 100% | ≤3h | - | No |

Performance Analysis

Guangdong Liyi stands out with the highest reorder rate (50%) and robust customization capacity, indicating strong customer retention and flexibility for OEM integration. Shandong Dekon and Dongguan Zhongli achieve perfect on-time delivery records (100%) with sub-3-hour response times, reflecting efficient internal coordination. While Guangdong-based firms dominate in product range and customization, Shandong exporters demonstrate reliability in fulfilling standardized orders. Suppliers with verified custom manufacturing status offer greater adaptability for non-standard force capacities, grip types, or environmental chamber integration. For high-volume procurement, prioritize partners with US$100,000+ annual online revenue and proven after-sales service responsiveness.

FAQs

How to verify tensile testing machine supplier credibility?

Cross-check claimed certifications (ISO, CE) through official registries. Request factory audit reports or video walkthroughs of production lines and QC stations. Analyze transaction history for consistent order fulfillment and review feedback related to software stability and mechanical durability.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQ at 1 set, enabling low-risk sampling. Bulk pricing typically applies at 5+ units, with discounts varying between 5–15% depending on configuration complexity.

Are customization services available for branding and specifications?

Yes, leading manufacturers offer full OEM/ODM support including custom color schemes, logos, software interfaces, and mechanical modifications (e.g., extended stroke length, specialized jigs). Turnaround for customized units averages 35–50 days.

What are common lead times and shipping options?

Standard machines ship within 25–40 days after order confirmation. Air freight delivers samples in 7–12 days; sea freight (FCL/LCL) takes 20–35 days depending on destination port. FOB terms are standard, though some suppliers offer CIF quoting upon request.

Do suppliers provide pre-shipment inspection and calibration?

Reputable exporters conduct final functional tests and provide basic calibration certificates. Third-party inspection (e.g., SGS, BV) can be arranged at buyer’s cost. Factory acceptance tests (FAT) via video call are recommended for first-time buyers.