Computer Numerical Control

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/2

1/2

1/3

1/3

CN

CN

1/9

1/9

1/3

1/3

1/22

1/22

1/3

1/3

1/7

1/7

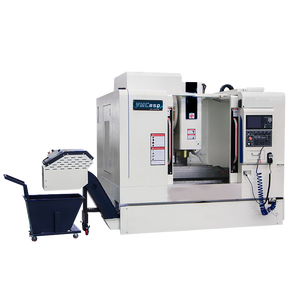

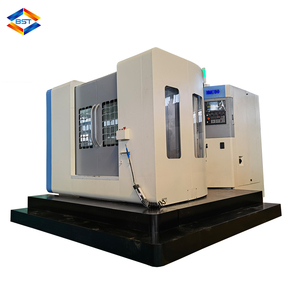

About computer numerical control

Where to Find Computer Numerical Control Machine Suppliers?

China remains the global epicenter for computer numerical control (CNC) machine manufacturing, with key industrial hubs concentrated in Guangdong, Shandong, and Jiangsu provinces. These regions host vertically integrated ecosystems that combine precision engineering, component sourcing, and export logistics within tightly connected supply chains. Shenzhen-based suppliers specialize in high-precision machining services and custom fabrication, leveraging proximity to semiconductor and electronics industries. Meanwhile, Shandong’s Jinan and Zaozhuang clusters focus on heavy-duty CNC milling machines, lathes, and machining centers, supported by regional steel production and mechanical engineering expertise.

The clustering effect enables significant operational efficiencies, including reduced material lead times, access to skilled technical labor, and streamlined shipping via major ports like Qingdao and Shekou. Suppliers in these zones typically operate under scalable production models, supporting both low-volume prototyping and bulk orders exceeding 100 units. Buyers benefit from shorter development cycles—average lead times range from 25 to 45 days for standard configurations—with many manufacturers offering modular designs to accelerate delivery. Localization of casting, sheet metal fabrication, and assembly processes contributes to 18–25% lower unit costs compared to equivalent machinery produced in Europe or North America.

How to Choose Computer Numerical Control Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

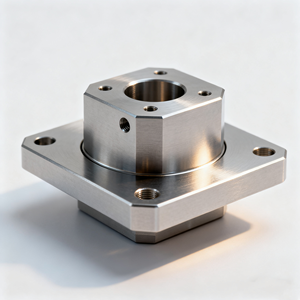

Technical Capability Verification

Confirm that suppliers support required machining types—such as 3-axis, 4-axis, or 5-axis milling, turning, EDM, or gantry routing—and offer compatibility with target materials (e.g., aluminum, stainless steel, titanium, composites). Review available customization options including anodized finishes, sandblasting, laser engraving, and custom tooling design. For integration into automated workflows, assess controller compatibility (e.g., Fanuc, GSK, Siemens).

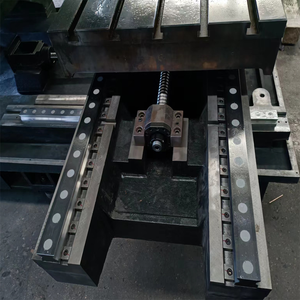

Production Infrastructure Assessment

Evaluate the following benchmarks during due diligence:

- Facility size indicative of production scale (suppliers with >5,000m² operations typically handle larger order volumes)

- In-house capabilities in casting, sheet metal fabrication, and CNC machining to reduce outsourcing dependencies

- Dedicated quality control stations with metrology equipment (e.g., CMMs, surface roughness testers)

- Engineering team availability for design-for-manufacturability feedback and drawing validation

Cross-reference declared response times (<1 hour preferred) and on-time delivery rates (>97%) with observed performance metrics where available.

Transaction and Quality Assurance

Prioritize suppliers demonstrating consistent reorder rates (≥30%) as an indicator of customer satisfaction. Verify adherence to international standards such as ISO 9001, CE marking for electrical systems, and RoHS compliance for environmental safety. Utilize secure payment mechanisms with milestone-based releases tied to production progress and pre-shipment inspections. Request sample units to validate dimensional accuracy, surface finish quality, and machine rigidity before full-scale procurement.

What Are the Best Computer Numerical Control Machine Suppliers?

| Company Name | Location | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Selection Hardware Technology Co.,Ltd. | Guangdong, CN | Custom Manufacturer | Machining Services, Casting Services, Sheet Metal Fabrication | US $2,300,000+ | 100% | ≤1h | 30% | Color, weight, packaging, sandblasting, label, 5-axis, material, size, drawings, anodized finish, turning, design, polishing, drawing, logo, 4-axis |

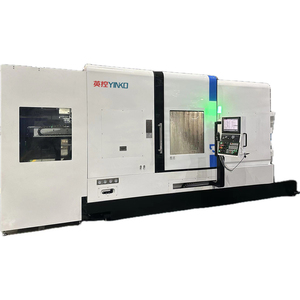

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | Equipment Manufacturer | CNC Lathe, Machining Centre, EDM Machines, Manual Mills, Wood Routers | US $1,100,000+ | 100% | ≤1h | 30% | Limited customization; focused on off-the-shelf CNC machines |

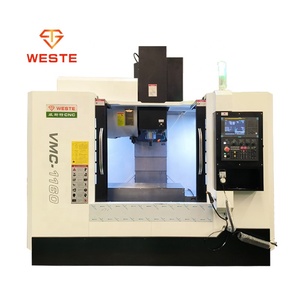

| Shandong Weste Cnc Machine Tool Co., Ltd. | Shandong, CN | Machine Tool Manufacturer | Machining Centre, CNC Milling Machines, CNC Lathe, Drilling Machines | US $50,000+ | 100% | ≤3h | 100% | Offers 3, 4, and 5-axis desktop and large-format milling solutions |

| Jinan Lingrui Cnc Machinery Co., Ltd. | Shandong, CN | Machinery Manufacturer | Wood Lathe, CNC Routers, Laser Cutting & Welding Systems | US $50+ | 100% | ≤1h | <15% | Specializes in multi-functional CNC routers and oscillating knife cutters |

| Shandong Optimetal Cnc Machine Co., Ltd. | Shandong, CN | Machine Manufacturer | CNC Lathe, Machining Centre, Surface Grinding, Band Saw Machines | US $4,000+ | - | ≤1h | <15% | Offers new models with Fanuc/GSK controls; limited public performance data |

Performance Analysis

ShenZhen Selection Hardware stands out for end-to-end custom manufacturing, backed by strong online revenue and comprehensive customization capabilities across materials, finishes, and geometries. Jinan Hongda and Shandong Weste provide robust CNC equipment portfolios, with Weste achieving a 100% reorder rate—indicative of high client retention despite lower digital visibility. All top-tier suppliers maintain 100% on-time delivery records, though response speed varies: three companies respond within one hour, enhancing communication efficiency for time-sensitive negotiations. Buyers seeking turnkey machining services should prioritize suppliers with documented post-processing capabilities (e.g., anodizing, polishing), while those procuring standalone machines should verify controller type, spindle power, and tool changer configuration prior to order placement.

FAQs

How to verify CNC machine supplier reliability?

Validate certifications through official registries and request evidence of internal quality management systems. Conduct virtual or on-site factory audits to confirm machining capacity, inventory levels, and QC protocols. Analyze historical transaction data, focusing on delivery consistency and post-sale service responsiveness.

What is the typical minimum order quantity (MOQ)?

Most suppliers set MOQ at 1 unit for CNC machines, allowing buyers to test performance before scaling. Custom machining services may require batch minimums depending on setup complexity, but many accommodate prototype runs.

Are customization requests supported?

Yes, leading suppliers offer extensive customization—from non-standard work envelope sizes to specialized control systems and finishing treatments. Provide detailed CAD models and technical specifications to enable accurate quoting and feasibility assessment.

Do suppliers provide technical documentation?

Reputable manufacturers supply operation manuals, electrical schematics, maintenance guides, and CE/ISO compliance documents. Confirm availability of English-language materials and software interfaces prior to purchase.

What are common payment and shipping terms?

Payment structures often include T/T (30% deposit, 70% before shipment) or platform-backed escrow arrangements. Shipping is typically FOB origin, though some suppliers arrange CIF terms for full-container loads. Air freight is viable for small routers or spare parts, while sea freight dominates for large machining centers.