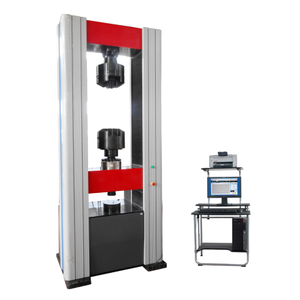

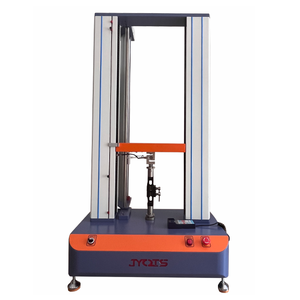

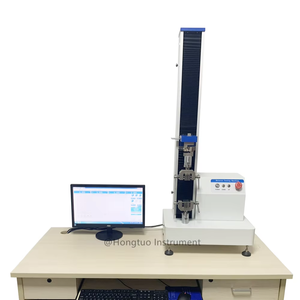

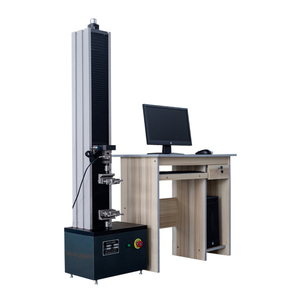

Computerised Universal Testing Machine

Top sponsor listing

Top sponsor listing

About computerised universal testing machine

Where to Find Computerised Universal Testing Machine Suppliers?

China remains the global hub for manufacturing computerised universal testing machines, with key production clusters concentrated in Guangdong and Hebei provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, advanced materials processing, and automated assembly lines. Dongguan and Guangzhou in Guangdong province are particularly notable for their specialization in high-precision testing equipment, supported by a dense network of component suppliers and R&D centers focused on material science and mechanical automation.

The industrial infrastructure enables scalable production, with many manufacturers operating facilities exceeding 5,000m² and equipped with CNC machining centers, servo-hydraulic calibration systems, and digital control integration lines. This localization reduces lead times for standard configurations to 20–35 days and allows cost efficiencies of 25–40% compared to equivalent Western or Indian manufacturers. Buyers benefit from access to modular designs, rapid prototyping capabilities, and flexible customization options in load capacity (ranging from 5KN to 6000KN), frame configuration (single/dual column), and software integration.

How to Choose Computerised Universal Testing Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional parameters:

Technical Compliance & Quality Assurance

Confirm adherence to international standards such as ISO 7500-1 (static mechanical testing), ASTM E4, and JIS B 7721. CE marking is essential for European market compliance, indicating conformity with safety, electromagnetic compatibility, and environmental directives. Request documentation on load cell calibration, strain measurement accuracy, and software validation protocols. Prioritize suppliers offering traceable certification from accredited third-party laboratories.

Production Capability Assessment

Evaluate core manufacturing competencies through the following indicators:

- Facility size ≥3,000m² with dedicated R&D and testing zones

- In-house machining capabilities including CNC milling, grinding, and servo-system integration

- Software development teams for custom control interfaces (Windows-based or PLC-driven)

- Monthly output capacity of at least 30–50 units for standard models

Cross-reference on-time delivery performance (target ≥95%) and reorder rates to assess operational stability and customer satisfaction.

Customization & Transaction Security

Verify the supplier’s ability to accommodate modifications in test space dimensions, gripping systems, environmental chambers (high/low temperature), and data acquisition software. Ensure support for multiple language interfaces and export-compatible power specifications (e.g., 220V/380V, 50/60Hz). Utilize secure payment mechanisms such as escrow services and insist on pre-shipment inspection rights. Sample testing against ASTM E8 or ISO 6892-1 tensile test benchmarks is strongly recommended before bulk orders.

What Are the Best Computerised Universal Testing Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Guangdong Newgoer Instrument Co., Ltd. | Testing Equipment, Tensile Testing Machine, Injection Molding Machines | US $450,000+ | 100% | ≤1h | 40% | Color, material, size, logo, packaging, label, graphic | Custom Manufacturer |

| Dongguan Haoen Automation Equipment Co., Ltd. | Testing Equipment, Tensile Testing Machine, Compression Testing Machine | US $40,000+ | 100% | ≤2h | <15% | Not specified | Not specified |

| Dongguan Hongjin Test Instrument Co., Ltd. | Testing Equipment, Rubber Product Making Machinery, Hydraulic Presses | US $800+ | 100% | ≤2h | - | Not specified | Not specified |

| Baoding Aofa Rigging Manufacturing Co., Ltd. | Tensile Testing Machine, Metal & Metallurgy Machinery, Hydraulic Presses | US $7,000+ | 100% | ≤6h | <15% | Not specified | Not specified |

| Dongguan Liyi Environmental Technology Co., Ltd. | Testing Equipment, Hardness Testers, Laboratory Heating Equipments | US $110,000+ | 90% | ≤8h | 20% | Not specified | Not specified |

Performance Analysis

Guangdong Newgoer stands out with the highest online revenue (US $450,000+), fastest response time (≤1 hour), and strongest customer retention (40% reorder rate), indicating robust service quality and production scalability. The company also offers extensive customization—covering aesthetics, materials, and branding—making it ideal for OEM partnerships. Dongguan Haoen and Baoding Aofa demonstrate perfect on-time delivery records but have lower reorder rates, suggesting room for improvement in post-sale engagement. Dongguan Liyi offers mid-range pricing and moderate responsiveness, though its 90% on-time delivery rate warrants due diligence for time-sensitive projects. All top-tier suppliers are based in Guangdong, reflecting the region’s dominance in precision instrumentation manufacturing.

FAQs

How to verify computerised universal testing machine supplier reliability?

Validate certifications (ISO, CE) through official registries and request factory audit reports. Assess technical capability via video tours of production and calibration labs. Analyze customer reviews focusing on after-sales support, software stability, and long-term equipment durability under continuous operation.

What is the typical lead time for standard and customized models?

Standard configurations typically ship within 20–30 days after order confirmation. Customized units with specialized grips, extended crossheads, or environmental chambers require 35–50 days, depending on complexity. Add 7–14 days for international air freight or 25–45 days for sea shipment.

Do suppliers offer MOQ flexibility?

Most suppliers list a minimum order quantity of 1 set, facilitating low-volume procurement for laboratories and SMEs. Bulk discounts generally apply for orders exceeding 5 units. Some manufacturers waive setup fees for repeat customers or long-term contracts.

Can software and interface be customized?

Yes, leading suppliers provide customizable control software with multi-language support (English, Spanish, Arabic, Russian), programmable test sequences, and data export functions (Excel, PDF). Advanced models support integration with lab management systems (LIMS) and feature real-time graphing and statistical analysis modules.

What are common load capacity ranges available?

Available capacities span from 5KN (500 kgf) for small material samples to 6000KN (600 metric tons) for heavy-duty structural testing. Mid-range models (100KN–500KN) are most commonly sourced for industrial QA labs, while single-column testers (5KN–30KN) serve research and polymer testing applications.