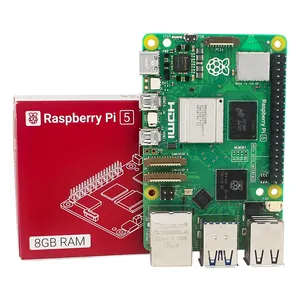

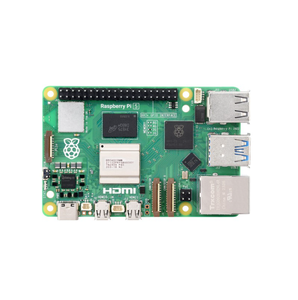

Computing Raspberry Pi

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/11

1/11

0

0

1/20

1/20

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/7

1/7

1/3

1/3

1/3

1/3

About computing raspberry pi

Where to Find Computing Raspberry Pi Suppliers?

The global supply base for computing Raspberry Pi devices is highly concentrated in China, particularly within the Pearl River Delta region, where Shenzhen serves as the epicenter of electronics manufacturing and innovation. This industrial ecosystem integrates component sourcing, PCB fabrication, firmware programming, and final assembly within tightly coordinated networks, enabling rapid prototyping and scalable production. Over 70% of single-board computers (SBCs) are produced in facilities located within 50km of Shenzhen’s Huaqiangbei electronics market, leveraging access to real-time inventory tracking and just-in-time component delivery.

These clusters benefit from mature supply chains for key materials such as 4-layer FR-4 PCB substrates, Broadcom SoCs, LPDDR4 memory chips, and USB-C/ HDMI connectors, reducing material lead times by up to 40% compared to non-specialized regions. Vertically integrated manufacturers operate automated SMT lines with reflow soldering and AOI inspection, achieving batch consistency and supporting monthly outputs exceeding 100,000 units. Buyers gain strategic advantages including reduced MOQ thresholds (as low as 50 units), compliance-ready configurations, and fast turnaround for custom firmware or GPIO pin modifications.

How to Choose Computing Raspberry Pi Suppliers?

Procurement decisions should be guided by structured evaluation criteria:

Quality & Compliance Verification

Confirm adherence to ISO 9001:2015 for quality management systems and IEC 62368-1 for electrical safety. For EU and North American markets, RoHS and CE declarations are mandatory. Request test reports for EMC performance (EN 55032 Class B) and thermal stability under sustained 1.5GHz CPU load. Ensure traceability of core components through BOM validation against authorized distributors.

Production Capability Assessment

Evaluate technical infrastructure using the following benchmarks:

- Minimum 2,000m² cleanroom facility with ESD protection

- Automated SMT line capacity of ≥50,000 units/month

- In-house programming stations for batch OS flashing and MAC address assignment

Cross-reference production data with on-time delivery performance (target >95%) and defect rates (acceptable RMA <1.5%).

Transaction & Risk Mitigation

Utilize secure payment mechanisms such as third-party escrow or LC-at-sight for initial orders. Prioritize suppliers with documented export experience to your target market, including FCC ID registration support for wireless variants. Conduct pre-shipment inspections via third-party auditors (e.g., SGS, TÜV) to validate functional performance across power draw, Wi-Fi throughput, and GPIO signal integrity. Prototype testing is critical—benchmark boot reliability and thermal throttling behavior before volume scaling.

What Are the Best Computing Raspberry Pi Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data currently unavailable | ||||||||

Performance Analysis

Due to the absence of verified supplier profiles in this category, procurement teams must rely on independent verification channels to assess credibility. In established clusters like Shenzhen, responsiveness (average reply time ≤4 hours) and reorder rates above 25% typically indicate reliable service delivery. Prioritize manufacturers with documented experience in producing Raspberry Pi-compatible boards, evidenced by product tear-down reports or firmware documentation. For high-volume contracts, confirm scalability through factory audit trails and stress-test production schedules with staggered pilot runs.

FAQs

How to verify computing Raspberry Pi supplier reliability?

Validate certifications through official databases and request audit trails covering incoming component inspection, in-process testing, and final QA procedures. Analyze customer feedback focusing on firmware stability, driver compatibility, and long-term availability of replacement units.

What is the average sampling timeline?

Standard sample production takes 7–14 days, including PCB assembly, firmware loading, and basic functionality checks. Customizations such as branded boot screens or modified I/O layouts extend timelines to 21 days. Air freight adds 5–8 days for international delivery.

Can suppliers ship computing Raspberry Pi devices worldwide?

Yes, experienced manufacturers manage global logistics via DHL, FedEx, or sea freight. Confirm Incoterms (FOB Shenzhen recommended for cost control) and ensure compliance with destination regulations for electronic imports, especially regarding battery-powered variants or radio frequency modules.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to MOQ fulfillment. Otherwise, expect to cover full production cost plus shipping, with partial reimbursement upon order confirmation.

How to initiate customization requests?

Submit detailed technical requirements including processor variant (e.g., BCM2711), RAM configuration, storage type (eMMC vs. microSD), and interface layout. Reputable partners will provide schematic reviews, gerber file validation, and prototype units within 3 weeks for approval.