Connecting Threads Thread

Top sponsor listing

Top sponsor listing

1/1

1/1

1/14

1/14

1/10

1/10

1/3

1/3

1/17

1/17

1/3

1/3

1/3

1/3

CN

CN

1/5

1/5

1/1

1/1

1/3

1/3

1/26

1/26

1/19

1/19

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/2

1/2

About connecting threads thread

Where to Source Connecting Threads Suppliers?

China remains the central hub for connecting threads manufacturing, with key suppliers concentrated in industrial regions including Guangdong, Jiangsu, and Anhui provinces. These areas host specialized producers of technical textiles, precision fasteners, and engineered fittings, supported by mature supply chains for synthetic fibers, metal alloys, and polymer materials. Dongguan and Guangzhou in Guangdong province are notable for high-volume textile thread production, while Taizhou in Jiangsu and Hefei in Anhui focus on industrial-grade threaded components used in hydraulic, pneumatic, and mechanical systems.

The regional ecosystems enable vertically integrated production—from raw material extrusion and coating to precision threading and packaging—reducing lead times by 20–30% compared to fragmented international supply bases. Suppliers benefit from proximity to ports like Shenzhen and Ningbo, facilitating efficient export logistics. Buyers can access both mass-produced standard threads and engineered solutions, with average monthly outputs ranging from 50,000 to over 500,000 units depending on product complexity and material type.

How to Evaluate Connecting Threads Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure quality, reliability, and compliance:

Technical and Material Specifications

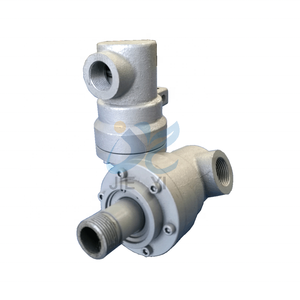

Confirm compatibility of thread materials (nylon, aramid, steel, plastic) with intended applications—textile bonding, fluid transfer, or mechanical assembly. For industrial fittings, verify thread standards (e.g., BSPT, JIC, NPT) and pressure ratings. Suppliers should provide detailed specifications including diameter, pitch, length, tensile strength, and temperature resistance.

Quality Assurance and Compliance

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates above 99% and low reorder rates (<15%) indicate robust internal controls. For export markets, ensure compliance with regional standards such as CE (Europe) or NSF/ANSI (North America), particularly for fluid-handling connectors.

Production and Customization Capabilities

Assess customization options across:

- Material selection (color, thickness, layer structure)

- Thread dimensions and configurations (male/female, straight/tapered)

- Branding (logo, packaging, labeling)

- Volume scalability (MOQs from 50 to 100 pieces typical)

Cross-reference supplier claims with online transaction volume indicators (e.g., reported annual revenues exceeding US $400,000) and response times (≤3 hours preferred) to gauge operational responsiveness.

What Are the Leading Connecting Threads Suppliers?

| Company Name | Specialization | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Notable Products |

|---|---|---|---|---|---|---|---|

| Dongguan Sovetl Special Rope & Webbing Co., Ltd. | Textile & Packaging Threads | US $190,000+ | 100% | ≤3h | <15% | Color, material, size, logo, packaging | Packaging ropes, sewing threads, aramid fabric thread |

| Anhui Fulaier E-Commerce Co., Ltd. | Metal Thread Components | US $400,000+ | 99% | ≤3h | <15% | Thread type, size, length, packaging, labeling | Male threads (1/2", M22), garden connectors |

| Taizhou Qingheng Machinery Co., Ltd. | Hydraulic & Industrial Fittings | US $50,000+ | 100% | ≤2h | 22% | Thread type, material, pressure rating, marking | BSPT external thread, JIC fittings, pressure gauge connectors |

| Suzhou Entenco Electromechanical Technology Co., Ltd. | Pneumatic & Plastic Connectors | US $130,000+ | 100% | ≤4h | <15% | Size, configuration, material, packaging | Quick connectors, Y-shaped tees, female thread fittings |

| Guangzhou Glamordove Beauty Supplies Co., Ltd. | Nylon Sewing Threads | US $70,000+ | 100% | ≤3h | 16% | Color, material, size, packaging | Bonded nylon weaving thread, multi-purpose sewing thread |

Performance Analysis

Anhui Fulaier leads in transaction volume (US $400,000+ revenue), suggesting strong export capacity and market penetration. Dongguan Sovetl and Suzhou Entenco demonstrate high reliability with 100% on-time delivery and low reorder rates, indicating customer satisfaction and consistent quality. Taizhou Qingheng stands out for rapid response (≤2h) and specialization in industrial hydraulic threads, though its higher reorder rate (22%) may reflect competitive pricing over long-term loyalty. Guangzhou Glamordove serves niche beauty and textile markets with bonded nylon threads, offering low MOQs (as low as 5 rolls), ideal for sample testing and small-batch procurement.

FAQs

How to verify connecting threads supplier reliability?

Evaluate on-time delivery performance (target ≥99%), response time (ideally ≤3h), and transaction history. Request product certifications, material test reports, and, where applicable, compliance documentation for fluid or mechanical safety standards. Conduct virtual factory audits to assess production lines and quality control procedures.

What is the typical minimum order quantity (MOQ)?

MOQs vary by product type: textile threads range from 5–30 rolls; metal and plastic fittings typically require 50–100 pieces. Some suppliers offer reduced MOQs for initial sampling, enabling cost-effective prototyping and quality validation.

Can suppliers customize thread specifications?

Yes, most suppliers support customization in material, color, diameter, length, and branding. Advanced options include pressure-rated fittings, tapered vs. straight threads, and OEM packaging. Technical drawings or samples are recommended to align specifications before bulk production.

What are common lead times for bulk orders?

Standard lead times range from 15–30 days after order confirmation, depending on customization level and production load. Expedited processing may reduce timelines to 10–15 days for non-complex items, particularly with suppliers reporting high online activity and streamlined operations.

Do suppliers support global shipping and logistics?

Yes, all listed suppliers have international transaction experience. Confirm Incoterms (FOB, CIF), shipping methods (air for samples, sea for bulk), and destination-specific import requirements for mechanical or fluid-handling components to avoid customs delays.