Continuous Casting Machine Manufacturers For Slabs

Top sponsor listing

Top sponsor listing

1/2

1/2

1/3

1/3

1/40

1/40

1/14

1/14

1/18

1/18

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/1

1/1

1/13

1/13

1/21

1/21

1/3

1/3

1/18

1/18

1/12

1/12

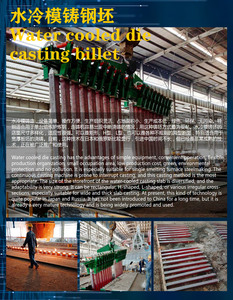

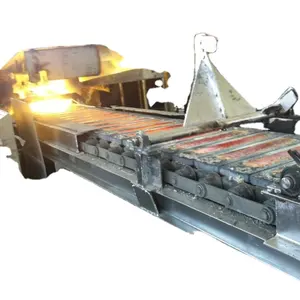

About continuous casting machine manufacturers for slabs

Where to Find Continuous Casting Machine Manufacturers for Slabs?

China remains the dominant hub for continuous casting machine manufacturing, particularly in specialized industrial zones such as Tangshan and Xi’an, where metallurgical equipment clusters support high-capacity production. These regions host vertically integrated facilities capable of delivering complete slab CCM systems—from design and fabrication to assembly and testing—under one roof. The concentration of steel processing infrastructure enables manufacturers to align closely with downstream rolling mills and foundries, reducing component lead times by up to 30%.

Suppliers in Tangshan, a core base for heavy machinery, leverage proximity to raw material sources and experienced engineering labor pools, allowing for rapid prototyping and large-scale deployment. Meanwhile, firms based in Xi’an emphasize R&D-driven customization and digital integration, offering PLC-controlled automation and energy-efficient designs. This regional specialization provides buyers with strategic options: cost-effective standard models from Tangshan-based producers or advanced, customized solutions from technology-focused suppliers in western China.

How to Choose Continuous Casting Machine Suppliers for Slabs?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify that suppliers offer ISO 9001-certified quality management systems as a baseline. For export markets, CE marking indicates compliance with European safety and environmental standards. Assess design proficiency through available product configurations—such as single-strand vs. multi-strand layouts, horizontal vs. vertical casting, and compatibility with billet-to-slab conversion processes. Request detailed schematics, control system specifications (e.g., Siemens or Allen-Bradley PLCs), and cooling system efficiency data.

Production Infrastructure Assessment

Evaluate key indicators of manufacturing maturity:

- Facility size supporting full-line assembly (minimum 5,000m² recommended)

- In-house capabilities in CNC machining, welding, and metallurgical component production

- Dedicated teams for process engineering and after-sales commissioning support

Cross-reference listed product ranges with actual production capacity. For instance, companies advertising over 100 metal casting machinery listings often operate established production lines with monthly outputs exceeding 5–10 units.

Transaction Reliability & After-Sales Support

Prioritize suppliers demonstrating consistent on-time delivery performance (target ≥98%). Confirm response times under 5 hours as an indicator of active order management. Review customization flexibility—including strand count, section size adaptation, and integration with existing furnace or rolling mill systems. Insist on third-party inspection protocols before shipment and verify availability of overseas installation supervision.

What Are the Leading Continuous Casting Machine Manufacturers for Slabs?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (Per Unit) |

|---|---|---|---|---|---|---|---|

| Tangshan Bohai Metallurgy Intelligent Equipment Co., Ltd. | Tangshan, CN | Metal Casting Machinery (144), Industrial Furnaces (36) | 100.0% | ≤5h | - | Section size, energy optimization, PLC brand | $411,000–413,000 |

| Tangshan Fengrun District Runhao Rolling Machinery Co., Ltd. | Tangshan, CN | Rolling Mills (1030), Metal Casting Machinery (132) | 100.0% | ≤3h | - | Steel grade adaptation, automation level | $26,000–30,000 / $2,600–3,000 |

| Xi'an Hani Tech Co., Ltd. | Xi’an, CN | Continuous Casting Machines (varied applications) | 100.0% | ≤4h | 20% | Color, material, size, logo, packaging | $70,000–300,000 |

| Jiaxing Jicheng Machinery Co., Ltd. | Jiaxing, CN | Aluminum & Brass CCM, Continuous Rolling Lines | 100.0% | ≤2h | - | Direct-chill casting, alloy-specific design | $80,000–$760,000 |

Performance Analysis

Tangshan-based suppliers dominate volume production and integration with traditional steelmaking flows, offering competitive pricing and proven reliability. Tangshan Bohai presents high-end slab CCM systems targeting large mills, while Runhao focuses on compact, lower-cost units suitable for mini-mills and secondary processors. Xi’an Hani Tech stands out for mid-range customization breadth and moderate reorder activity, indicating growing international traction. Jiaxing Jicheng distinguishes itself with non-ferrous casting expertise, particularly in aluminum and brass slab casting—a niche capability among generalist suppliers. Buyers seeking specialized metallurgical adaptations should prioritize vendors with documented experience in relevant alloys and cooling dynamics.

FAQs

How to verify continuous casting machine manufacturer reliability?

Confirm ISO 9001 or equivalent certification status through issuing body records. Request factory audit reports or video walkthroughs highlighting CNC workshops, welding bays, and final assembly zones. Analyze customer feedback focusing on equipment uptime, mold alignment accuracy, and post-installation troubleshooting responsiveness.

What is the typical lead time for slab continuous casting machines?

Standard configurations require 60–90 days from deposit confirmation. Customized systems involving PLC programming, non-standard strand arrangements, or integration with upstream furnaces may extend to 120 days. Expedited builds are possible with premium fees, depending on factory workload.

Do manufacturers support global shipping and installation?

Yes, most suppliers coordinate FOB or CIF shipments via sea freight, with containerized or flat-rack loading based on unit dimensions. Many offer optional technician dispatch services for on-site commissioning and operator training, typically at additional cost. Confirm incoterms, insurance coverage, and import compliance assistance during negotiation.

Can I request a sample or prototype before full procurement?

Full machine sampling is uncommon due to scale and cost; however, suppliers often provide subsystem demonstrations—such as tundish feeding mechanisms or roller bed alignment tests—via video or factory visits. Some offer modular pre-assembly checks with client witnesses. For new designs, expect prototype validation timelines of 8–12 weeks.

What customization options are commonly available?

Key configurable parameters include strand count (1–8 strands), cross-section range (e.g., 150×150mm to 300×450mm slabs), withdrawal speed, secondary cooling intensity, and automation level (manual, semi-auto, fully automatic). Buyers can also specify motor brands, control panel interfaces, and structural coatings for corrosion resistance in humid environments.