Contract Cnc Programming

1/28

1/28

1/30

1/30

1/24

1/24

1/18

1/18

1/32

1/32

1/29

1/29

1/17

1/17

1/9

1/9

1/35

1/35

1/21

1/21

1/28

1/28

1/58

1/58

1/11

1/11

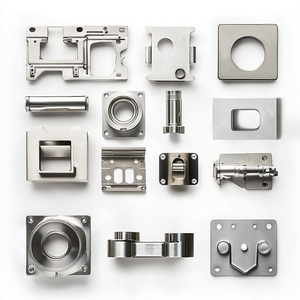

About contract cnc programming

Where to Find Contract CNC Programming Suppliers?

China remains the global epicenter for contract CNC programming and precision machining services, with concentrated supplier clusters in Fujian, Shanghai, Guangdong, and Zhejiang provinces. These regions host vertically integrated manufacturing ecosystems that combine advanced CNC infrastructure with scalable labor pools and robust material supply chains. Xiamen and Shenzhen are particularly notable for high-mix, low-to-medium volume production, serving industries ranging from consumer electronics to industrial automation.

The geographic clustering enables rapid prototyping and agile production cycles, supported by localized access to raw materials such as aluminum, stainless steel, brass, and engineering plastics. Facilities typically operate 24/7 shifts across multi-axis CNC lathes, milling centers, wire EDM, and laser cutting systems. This integration reduces component lead times by 25–40% compared to decentralized models, while maintaining tight tolerances (±0.005mm). Buyers benefit from proximity to ports like Xiamen and Shenzhen, enabling efficient air and sea freight logistics for global distribution.

How to Choose Contract CNC Programming Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Prioritize suppliers with ISO 9001 certification as a baseline indicator of quality management. For export-oriented buyers, confirm adherence to international standards such as RoHS, CE (where applicable), and AS9100 for aerospace components. Verify process documentation including GD&T drawings, first-article inspection reports, and material traceability records. In-house metrology labs equipped with CMMs and optical comparators are essential for consistent quality assurance.

Production Capability Assessment

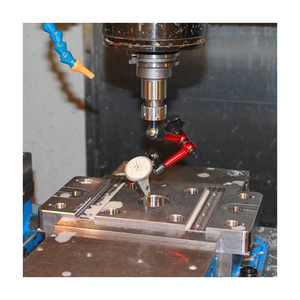

Evaluate core competencies through the following criteria:

- Minimum facility size of 1,000m² indicating capacity for dedicated production lines

- In-house CNC programming teams using software such as Mastercam, SolidWorks, or Siemens NX

- Range of compatible materials: aluminum (6061, 7075), stainless steel (303, 304, 316), titanium, brass, and engineered polymers

- Secondary processing capabilities including anodizing, plating, sandblasting, and laser engraving

Cross-reference on-time delivery rates (>95%) and response times (<4 hours) as proxies for operational efficiency.

Transaction & Risk Mitigation

Utilize secure payment mechanisms such as escrow or milestone-based disbursements tied to production checkpoints. Review supplier transaction history, focusing on reorder rates (ideally >35%) and dispute resolution performance. Request physical or digital samples before full-scale orders—prototypes should be deliverable within 7–14 days for standard parts.

What Are the Best Contract CNC Programming Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Xiamen HYM Metal Products Co., Ltd. | Fujian, CN | Multispecialty Supplier | US $2,600,000+ | 94% | ≤4h | 55% | 1–3 pcs | $0.10–5.00 |

| Shanghai Starway Engineering & Manufacturing Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $4,300,000+ | 99% | ≤3h | 37% | 1 pc | $0.20–8.00 |

| Shenzhen SLD Precision Hardware Co., Ltd | Guangdong, CN | Custom Manufacturer | US $440,000+ | 100% | ≤2h | 40% | 1 pc | $0.20–1.20 |

| Dongguan Shipai Jingqi Hardware Products Factory | Guangdong, CN | Not Specified | US $10,000+ | 100% | ≤1h | <15% | 1 pc | $0.39–7.00 |

| Hangzhou Aoyi Trade Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | US $180,000+ | 96% | ≤3h | 57% | 2–5 pcs | $0.10–0.90 |

Performance Analysis

Shanghai- and Shenzhen-based manufacturers demonstrate strong technical scalability and responsiveness, with two suppliers achieving 100% on-time delivery. Xiamen HYM and Hangzhou Aoyi stand out for high reorder rates (55% and 57%), suggesting superior customer satisfaction in niche customization and small-batch fulfillment. While Dongguan Shipai Jingqi offers the fastest average response time (≤1 hour), its sub-15% reorder rate may indicate limitations in post-sale support or consistency.

Suppliers in this segment commonly support MOQs as low as one piece, making them ideal for prototyping and R&D projects. Pricing is highly competitive, starting at $0.10/unit for simple geometries in bulk micro-orders. For complex, high-precision components requiring multi-axis programming, expect pricing above $2.00/unit with extended setup times. Buyers should prioritize partners offering full design-for-manufacturability (DFM) feedback and CAD/CAM file compatibility.

FAQs

How to verify contract CNC programming supplier reliability?

Cross-validate certifications (e.g., ISO 9001) through official registries. Request evidence of in-house programming and machine ownership—not subcontracted operations. Analyze customer reviews focused on dimensional accuracy, communication clarity, and revision handling.

What is the typical lead time for CNC programming and part production?

Standard lead times range from 7–15 days for prototype batches. High-complexity parts involving 5-axis machining or exotic materials may require 20–25 days. Rush services are available from select suppliers within 3–5 days at a premium.

Can suppliers handle full turnkey manufacturing?

Yes, leading providers offer end-to-end services including CNC programming, raw material sourcing, machining, surface treatment, assembly, and packaging. Confirm vertical integration depth before awarding contracts requiring secondary processes.

Do CNC programming suppliers accept partial payments or milestones?

Many suppliers support staged payments—typically 30–50% upfront for tooling/setup, with balance due pre-shipment. Escrow arrangements are recommended for first-time transactions exceeding $5,000.

How to initiate a custom CNC programming request?

Submit detailed technical files in STEP, IGES, or DWG formats, accompanied by material specifications, tolerance requirements, and desired surface finishes. Reputable suppliers will return a DFM report and quotation within 24–48 hours.