Controller Vibration Tester

1/3

1/3

1/11

1/11

1/3

1/3

1/3

1/3

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/15

1/15

1/3

1/3

1/3

1/3

0

0

1/8

1/8

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

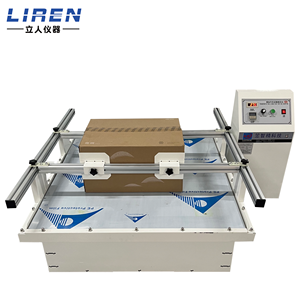

About controller vibration tester

Where to Find Controller Vibration Tester Suppliers?

China remains the central hub for controller vibration tester manufacturing, with key industrial clusters in Guangdong, Shandong, and Shaanxi provinces driving innovation and volume production. Guangdong's Dongguan and Foshan regions host specialized automation equipment suppliers that integrate advanced electromagnetic actuator technologies into compact, high-frequency testing systems. These zones benefit from proximity to semiconductor and electronics manufacturing centers, enabling rapid prototyping and component sourcing.

The supply ecosystem is characterized by vertically integrated operations—many suppliers manage full production cycles from PCB assembly to final calibration. This integration supports lead times averaging 15–30 days for standard units and allows flexibility for custom configurations. Regional advantages include access to precision machining services, established export logistics networks, and compliance-ready design frameworks aligned with international EMC and safety standards. Buyers can leverage competitive pricing due to localized component sourcing, with cost efficiencies ranging from 20–40% compared to European or North American manufacturers.

How to Choose Controller Vibration Tester Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

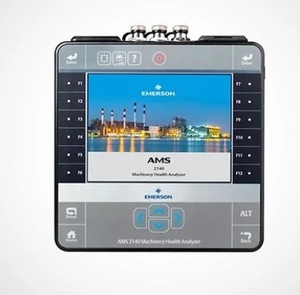

Confirm that suppliers offer products compliant with IEC 60068-2-6 (sinusoidal vibration) and IEC 60068-2-64 (random vibration) test standards. For industrial or aerospace applications, verify controller compatibility with multi-axis testing, real-time signal processing, and data acquisition integration. Suppliers should provide detailed specifications including frequency range (e.g., 1–2000 Hz), acceleration capacity, and control software features such as closed-loop feedback and waveform synthesis.

Production & Quality Infrastructure

Assess core capabilities through these indicators:

- Minimum of 10+ dedicated testing equipment listings indicating product specialization

- In-house R&D or firmware development for controller programming and calibration

- On-site signal analysis tools and environmental simulation setups for pre-shipment validation

Prioritize suppliers reporting on-time delivery rates ≥90% and response times ≤2 hours, which correlate with operational responsiveness and order management efficiency.

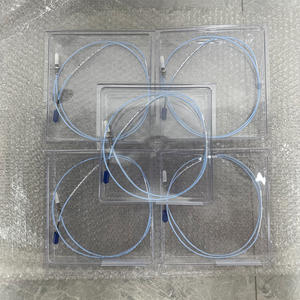

Procurement Risk Mitigation

Utilize secure payment mechanisms tied to performance milestones. Request sample units for functional testing—particularly for controller stability under extended operation and synchronization accuracy with shaker tables. Validate packaging integrity for shock-sensitive electronics during transit. Review after-sales support policies, especially regarding firmware updates, sensor recalibration, and remote diagnostics availability.

What Are the Best Controller Vibration Tester Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Dongguan Haoen Automation Equipment Co., Ltd. | Guangdong, CN | Testing Equipment (169) | US $30,000+ | 100% | ≤1h | <15% | No data |

| Xi'an Taimaoda Automation Equipment Co., Ltd. | Shaanxi, CN | Testing Equipment (Multiple) | US $190,000+ | 90% | ≤1h | 18% | Color, material, size, logo, packaging, label, graphic |

| Guangdong Jianqiao Testing Equipment Co., Ltd. | Guangdong, CN | Testing Equipment (76) | Not disclosed | 100% | ≤2h | Not disclosed | No data |

| Yangzhou Zhenzhong Testing Technology Co., Ltd. | Jiangsu, CN | Other Test Instruments (160) | US $2,000+ | 100% | ≤4h | <15% | No data |

| Shandong Taisheng Power Equipment Co., Ltd. | Shandong, CN | PLC, PAC, & Dedicated Controllers (159) | US $2,000+ | 100% | ≤1h | <15% | No data |

Performance Analysis

Dongguan Haoen and Guangdong Jianqiao demonstrate strong reliability with 100% on-time delivery records and extensive portfolios focused on electromagnetic vibration systems. Xi'an Taimaoda stands out for customization breadth and higher reorder rate (18%), suggesting customer satisfaction with tailored solutions despite slightly lower fulfillment consistency. Shandong Taisheng specializes in control hardware, offering robust PLC-integrated transmitters suitable for industrial monitoring applications. Yangzhou Zhenzhong provides high-end signal analyzers and multi-channel controllers, ideal for complex data acquisition needs. Suppliers with revenue exceeding US $30,000 online typically maintain better inventory visibility and technical documentation quality, supporting smoother procurement cycles.

FAQs

What certifications should a vibration tester controller supplier have?

While not all suppliers list ISO or CE certifications explicitly, prioritize those whose products align with IEC 61010 (safety requirements for electrical equipment) and IEC 61326 (EMC for measurement devices). Third-party test reports verifying frequency accuracy, harmonic distortion, and thermal stability are critical for mission-critical applications.

What is the typical MOQ and pricing range?

Standard MOQ is 1 set for complete vibration test systems, though some controllers or sensors require minimum orders of 5 pieces. Pricing varies significantly: basic electromagnetic testers start at $599/set, while high-frequency or multi-axis systems reach $50,000+. Dedicated controllers and signal analyzers range from $2,650 to over $10,000 depending on channel count and software capabilities.

Can suppliers customize controller firmware or interfaces?

Yes, select suppliers offer interface localization, protocol adaptation (e.g., MODBUS, CAN bus), and custom control algorithms. Xi'an Taimaoda explicitly lists customization options, including branding and physical modifications. For deep firmware changes, confirm the presence of an in-house software team and request source code escrow agreements if applicable.

What is the average lead time for customized vibration testers?

Standard units ship within 15–20 days. Customized configurations involving modified frequency ranges, non-standard table sizes, or proprietary control logic typically require 30–45 days. Complex integrations with environmental chambers or transport simulation systems may extend timelines to 60 days.

Do suppliers provide calibration certificates or post-sale support?

Reputable suppliers issue出厂 calibration reports traceable to national standards. Post-sale services vary—verify availability of remote troubleshooting, periodic recalibration, and spare parts supply before purchase. Some suppliers include one-year warranties covering controller and amplifier modules.