Controlling Engineering

Top sponsor listing

Top sponsor listing

1/3

1/3

1/2

1/2

1/3

1/3

1/17

1/17

1/3

1/3

1/7

1/7

1/3

1/3

1/3

1/3

1/2

1/2

CN

CN

1/6

1/6

1/3

1/3

0

0

1/27

1/27

1/3

1/3

1/18

1/18

1/3

1/3

1/16

1/16

CN

CN

1/3

1/3

0

0

About controlling engineering

Where to Find Controlling Engineering Suppliers?

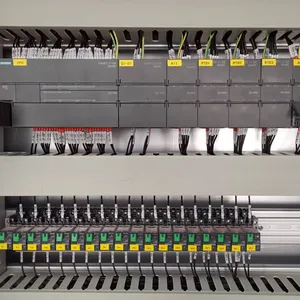

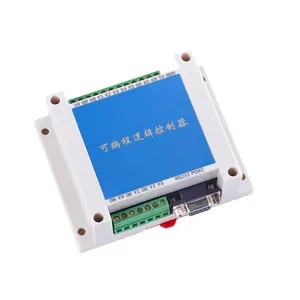

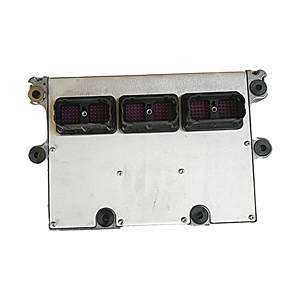

No verified controlling engineering suppliers are currently available in the dataset. As a result, no industrial clusters or regional manufacturing hubs can be identified for this specialization based on existing supplier records. Typically, controlling engineering services—encompassing automation system design, control panel fabrication, PLC programming, and process optimization—are delivered by engineering firms integrated within broader industrial ecosystems. In mature markets, such providers are often concentrated near advanced manufacturing zones, energy facilities, or transportation infrastructure corridors where demand for precision control systems is highest.

In the absence of active suppliers, buyers should consider adjacent regions known for strong engineering service capabilities, such as the Yangtze River Delta in China (Shanghai, Suzhou, Wuxi), Germany’s Baden-Württemberg region, or the Midwest United States, which historically support high concentrations of industrial automation expertise. These areas feature skilled labor pools, technical institutions, and established supply networks for electrical components, sensors, and embedded systems critical to controlling engineering projects.

How to Choose Controlling Engineering Suppliers?

Due to the absence of listed suppliers, selection criteria must remain general but should focus on verifiable technical and operational benchmarks when candidates emerge:

Technical Compliance

Require documented adherence to international standards such as ISO 9001 for quality management, IEC 61131-3 for PLC programming, and IEC 60204-1 for safety of machinery control systems. For projects in regulated industries (e.g., pharmaceuticals, energy, aerospace), compliance with sector-specific frameworks like ISA-88 or ISA-95 is essential. Request proof of software validation protocols and version control procedures for control logic development.

Production and Engineering Capability Audits

Assess the supplier’s engineering infrastructure through direct verification:

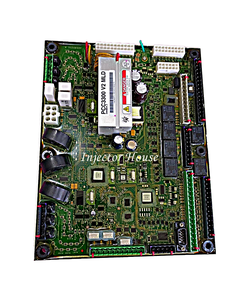

- Minimum team size of 15+ engineers with documented experience in SCADA, HMI, and drive integration

- Evidence of in-house testing facilities for control panels (dielectric strength, thermal cycling, vibration)

- Use of standardized engineering tools (e.g., EPLAN, TIA Portal, AutoCAD Electrical)

Cross-reference project portfolios with on-time commissioning rates (target >95%) to evaluate execution reliability.

Transaction Safeguards

Implement milestone-based payment structures tied to design review, FAT (Factory Acceptance Testing), and SAT (Site Acceptance Testing) sign-offs. Prioritize partners who provide detailed documentation packages—including loop diagrams, wiring schematics, and cybersecurity configurations—and offer post-commissioning support. Third-party inspection agreements should be formalized prior to contract finalization.

What Are the Best Controlling Engineering Suppliers?

No suppliers are listed in the current dataset for controlling engineering services. As a result, no performance comparisons or rankings can be generated. Buyers are advised to conduct proactive market scanning through industry registries, trade associations (e.g., IEEE, ISA, GAMBICA), or technical exhibitions focused on industrial automation to identify qualified vendors. When evaluating new partners, verify project references in similar process environments (e.g., batch vs. continuous manufacturing) and assess scalability for multi-site deployments.

FAQs

How to verify controlling engineering supplier reliability?

Validate professional certifications (e.g., Certified Automation Professional – CAP), audit project histories, and request client testimonials from comparable industrial sectors. Confirm participation in independent quality audits and adherence to change management protocols during system implementation.

What is the average sampling or prototyping timeline?

Control system prototyping typically requires 4–6 weeks for design, hardware assembly, and logic testing. Simulated FAT execution adds 1–2 weeks. Complex integrations involving legacy equipment or safety-rated functions may extend timelines to 10–12 weeks.

Can controlling engineering suppliers support global deployments?

Yes, experienced firms manage international projects with localized compliance adaptations. Confirm familiarity with regional electrical codes (e.g., NEC in North America, GB standards in China) and language-specific documentation capabilities. Remote monitoring and virtual commissioning are increasingly offered to reduce travel dependencies.

Do engineering suppliers provide free design consultations?

Policies vary. Some firms offer complimentary preliminary assessments for long-term contracts or turnkey projects. Detailed engineering proposals usually involve paid scoping engagements, particularly for custom architectures or regulatory-critical applications.

How to initiate customization requests?

Submit functional specifications including control architecture (centralized vs. distributed), communication protocols (PROFINET, Modbus TCP, EtherCAT), redundancy requirements, and environmental conditions. Reputable suppliers respond with system schematics, bill of materials, and risk assessment reports within 5–7 business days.