Controlling The Production Process

Top sponsor listing

Top sponsor listing

About controlling the production process

Where to Find Production Control Systems Suppliers?

China remains a dominant hub for production control systems manufacturing, with key supplier clusters concentrated in Guangdong and Fujian provinces. Shenzhen, within Guangdong, hosts advanced electronics and automation firms leveraging proximity to semiconductor supply chains and high-precision component manufacturers. This region supports rapid prototyping and integration of programmable logic controllers (PLCs), human-machine interfaces (HMIs), and variable frequency drives (VFDs). Fujian-based suppliers, particularly around Fuzhou, focus on modular control units and industrial PC integration, benefiting from regional specialization in embedded systems and firmware development.

These industrial ecosystems enable vertically integrated production, where design, assembly, and testing occur within compact geographic zones. Suppliers access mature networks of electronic component vendors, PCB fabricators, and software engineers, reducing system integration time by 20–35% compared to decentralized models. Buyers benefit from scalable output—standard control modules typically have lead times of 15–30 days—with options for OEM customization. Localized logistics further reduce costs, offering 15–25% savings on unit production versus Western alternatives, especially for medium-to-high-volume orders.

How to Choose Production Control Systems Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Product Range

Confirm supplier expertise in core automation components such as PLCs, PACs, HMIs, and motor drivers. Prioritize companies demonstrating consistent product lines in industrial control hardware. Verify compatibility with common industrial protocols (e.g., Modbus, Profibus, EtherNet/IP) and support for SCADA integration. For regulated industries, ensure compliance with IEC 61131-3 standards for controller programming and CE or RoHS certification where applicable.

Production Capability Verification

Assess infrastructure indicators including:

- Facility scale supporting batch or continuous production

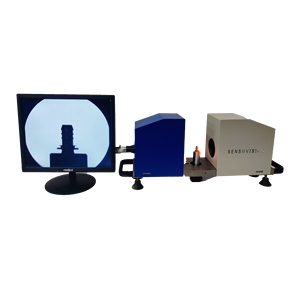

- In-house testing capabilities for electromagnetic compatibility (EMC) and thermal stress

- Presence of dedicated R&D teams for firmware updates and custom logic development

Cross-reference online revenue metrics and reorder rates as proxies for market validation. Target suppliers with verified on-time delivery performance above 95%.

Transaction Safeguards & After-Sales Support

Utilize secure payment frameworks that align financial release with delivery milestones. Evaluate response times (ideally ≤2 hours) and language proficiency for efficient troubleshooting. Request firmware version logs and backup configuration files as part of post-installation support. Pre-shipment inspection protocols should include functional testing under simulated load conditions to validate system stability.

What Are the Best Production Control Systems Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Product Examples | Min. Order Value |

|---|---|---|---|---|---|---|---|

| Shenzhen Yuetian Micro Technology Co., Ltd. | PLC, PAC, Relays, HMIs, VFDs | 99% | 51% | ≤2h | US $1,400,000+ | Industrial control modules, automation panels | $76–$484 |

| JCT DEVELOPMENT TECHNOLOGY COMPANY LIMITED | Reactors, Mixing Equipment, Extruders | - | - | ≤2h | - | Hot melt adhesive production lines ($58k–$88k) | $49,000 |

| Fuzhou Fouwell Technology Co., Ltd. | PLC Controller Modules, HMI Units | 96% | 22% | ≤2h | US $100,000+ | Original PLC modules ($76–$484) | $76 |

| Sumec Industrial INC | Pasteurizers, Sterilization Systems | - | - | ≤1h | - | Milk processing control units ($250–$3,000) | $250 |

| Fancy Machinery Co., Ltd. | CNC Controllers, Motor Drivers | 66% | 16% | ≤1h | US $10,000+ | GSK-series CNC systems ($780–$2,150) | $780 |

Performance Analysis

Shenzhen Yuetian Micro Technology stands out with a 99% on-time delivery rate and a 51% reorder rate, indicating strong customer retention and process reliability. Its broad product portfolio and high online revenue suggest established market presence and scalability. Fuzhou Fouwell offers cost-effective entry points for discrete PLC modules, though its lower reorder rate may reflect limited after-sales engagement. JCT Development targets high-value process lines, with minimum orders exceeding $58,000, positioning it for large-scale industrial integrators. Sumec Industrial provides niche solutions in food processing automation at competitive entry prices, while Fancy Machinery focuses on CNC-specific control systems with moderate delivery performance. Buyers seeking standardized components should prioritize suppliers with documented delivery records and firmware update cycles.

FAQs

How to verify production control system supplier reliability?

Validate technical claims through product documentation, including datasheets, firmware revision history, and protocol compatibility lists. Request evidence of quality management systems (e.g., ISO 9001) and review transactional metrics such as on-time delivery and response consistency. Conduct video audits of testing procedures and inventory management practices to assess operational maturity.

What is the typical MOQ and lead time?

For standard PLC or HMI units, MOQ starts at one piece with lead times of 7–15 days. Custom panel assemblies or integrated control cabinets may require minimum orders of 5–10 units and 20–35 days for completion. High-complexity systems, such as full-line automation packages, can extend to 45 days depending on software configuration requirements.

Can suppliers provide customized control logic or branding?

Yes, many suppliers offer OEM labeling and custom firmware loading. Capabilities vary: established firms like Shenzhen Yuetian support IEC 61131-3 programming for user-defined logic, while others may limit customization to HMI screen layouts and device branding. Confirm source code accessibility and update mechanisms before procurement.

Do suppliers support international voltage and safety standards?

Most manufacturers produce dual-voltage compatible units (110V/220V) and comply with CE or CCC certifications. For export markets, verify inclusion of protective relays, proper grounding design, and EMC shielding. Suppliers should provide test reports from accredited labs upon request.

How are software updates and technical support handled?

Support models differ: some suppliers deliver firmware updates via encrypted USB loaders, while others offer cloud-based monitoring integration. Post-sale assistance ranges from email-only communication to 24/7 remote diagnostics. Clarify service level agreements (SLAs) for bug resolution and lifecycle support prior to contract finalization.