Converting Factory

Top sponsor listing

Top sponsor listing

CN

CN

1/22

1/22

0

0

1/18

1/18

1/16

1/16

0

0

1/3

1/3

1/30

1/30

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

0

0

1/3

1/3

1/3

1/3

CN

CN

1/22

1/22

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/3

1/3

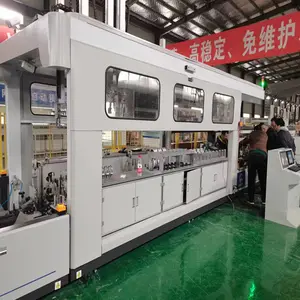

About converting factory

Where to Find Converting Factory Suppliers?

China remains the global epicenter for converting factory equipment manufacturing, with key industrial clusters in Hebei, Shandong, and Guangdong provinces driving innovation and scale. Hebei specializes in food processing and packaging lines, leveraging proximity to agricultural raw materials and state-certified production facilities. Shandong has emerged as a hub for heavy machinery integration, particularly in gluing, coating, and panel assembly systems, supported by robust metalworking supply chains. Meanwhile, Guangdong’s Pearl River Delta region excels in high-precision electronics and home appliance automation lines, benefiting from dense networks of component suppliers and R&D centers.

These regional ecosystems enable vertically integrated operations—from design and fabrication to full-line commissioning—reducing lead times and enhancing customization agility. Suppliers in these zones typically operate under standardized quality frameworks, with many maintaining ISO-aligned processes. Buyers can expect average delivery cycles of 30–60 days for automated production systems, depending on complexity, alongside cost advantages of 20–35% compared to equivalent Western-built solutions. The concentration of engineering talent and modular system designs further supports rapid deployment of turnkey converting lines.

How to Choose Converting Factory Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Production Infrastructure Verification

Confirm suppliers operate dedicated production facilities with in-house engineering and assembly capabilities. Key indicators include facility size (minimum 2,000m² recommended), presence of CNC machining or robotic integration, and evidence of end-to-end project execution. Video audits or site visits should verify automation cell layouts, testing benches, and quality inspection stations.

Quality and Compliance Standards

Prioritize suppliers adhering to recognized quality management systems such as ISO 9001. For export markets, CE marking is essential for electrical safety compliance in Europe, while UL/CSA standards apply for North American deployments. Request documentation on material traceability, weld integrity testing, and control system certifications (e.g., PLC firmware validation).

Customization and Technical Support

Evaluate suppliers based on documented customization scope:

- Design flexibility for layout, throughput, and integration with existing ERP/MES systems

- Support for material-specific configurations (e.g., stainless steel for food-grade lines)

- Provision of 3D models, process flow diagrams, and post-installation commissioning support

Cross-reference claimed capabilities with product listings and client case studies where available.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as letter of credit or escrow services until final acceptance testing is completed. Analyze supplier performance metrics including on-time delivery rate (target ≥95%), response time (ideally ≤4 hours), and reorder frequency. High reorder rates indicate customer satisfaction, while low repeat orders may signal integration or reliability issues.

What Are the Best Converting Factory Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Hebei Tomato Group Ltd. | Ketchup (449), Canned Seafood (97), Mixed Spices & Seasonings (61) | 90% | ≤4h | <15% | US $330,000+ | Color, nutrition facts, taste, packaging, label, oil, material, size, design, logo, graphic |

| Anping County Laien Wire Mesh Machine Manufacturing Co., Ltd. | Cold-rolled ribbed wire mesh production line | 100% | ≤1h | <15% | US $30,000+ | Color, material, size, logo, packaging, label, graphic |

| Shandong Xulida Machinery Co., Ltd. | Gluing Machines (835), Wood Based Panels Machinery (49) | 100% | ≤1h | <15% | US $10,000+ | N/A |

| Guangdong Huixing Hitech Co., Ltd. | Automated Assembly Line, LCD/TV Production Line, Washing Machine Line | - | ≤23h | 100% | US $80+ | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Hongdali Machinery Co., Ltd. | Air Conditioner, TV, Mobile Phone, Home Appliance Production Lines | 100% | ≤3h | 75% | US $20,000+ | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Suppliers like Anping County Laien and Shandong Xulida demonstrate strong operational discipline with 100% on-time delivery and sub-1-hour response times, indicating efficient internal coordination. Shenzhen Hongdali stands out with a 75% reorder rate, suggesting high client retention likely due to responsive customization and system reliability. In contrast, Hebei Tomato Group offers extensive product diversity in food processing but exhibits a low reorder rate, potentially reflecting niche market positioning or one-off project engagements. Guangdong Huixing Hitech reports a 100% reorder rate despite slower response times, which may indicate long-term contract relationships or post-sale service effectiveness. Buyers seeking scalable automation should prioritize suppliers with proven track records in system integration and after-sales support.

FAQs

How to verify converting factory supplier credibility?

Validate certifications through official registries and request audit trails covering design, fabrication, and testing phases. Review transaction history, customer testimonials, and third-party inspection reports. Conduct virtual factory tours to assess equipment, workforce density, and workflow organization.

What is the typical minimum order quantity (MOQ) for converting lines?

Most suppliers list MOQs as "1 set" for complete production lines. However, pricing and lead time vary significantly based on configuration. Modular units may allow phased procurement, though full-line orders often secure better unit economics.

What are common lead times for custom converting factories?

Standard automated lines require 30–45 days for manufacturing and testing. Complex systems involving multi-stage processes or specialized materials (e.g., food-grade stainless steel) may take 60–90 days. Rush orders with expedited fees can reduce timelines by 15–25%.

Do suppliers offer installation and training services?

Yes, most established suppliers provide remote or on-site commissioning, operator training, and troubleshooting support. These services are typically quoted separately and may include travel costs for international deployments. Confirm service scope and SLAs before contract finalization.

Can converting lines be retrofitted into existing facilities?

Many suppliers design modular systems compatible with legacy infrastructure. Provide floor plans, power specifications, and throughput requirements to ensure seamless integration. Reputable manufacturers conduct site assessments prior to engineering final designs.