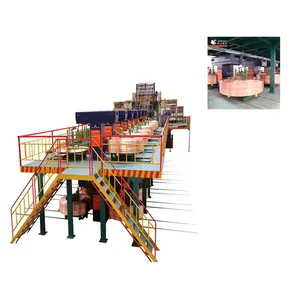

Copper Rod Continuous Casting Machine Distributor

Top sponsor listing

Top sponsor listing

About copper rod continuous casting machine distributor

Where to Find Copper Rod Continuous Casting Machine Distributors?

China remains the central hub for copper rod continuous casting machine manufacturing, with key industrial clusters in Henan and Zhejiang provinces driving supply chain efficiency. Henan’s machinery sector benefits from proximity to non-ferrous metal smelters and integrated logistics networks, enabling streamlined raw material access and outbound distribution. Jiaxing in Zhejiang hosts specialized engineering firms focused on precision metallurgical equipment, leveraging regional expertise in automation and process control systems.

These regions support vertically integrated production ecosystems where furnace systems, casting lines, and downstream wire drawing units are co-engineered. Suppliers typically operate multi-disciplinary facilities capable of delivering turnkey production lines. Buyers benefit from localized component sourcing, reducing lead times for standard configurations to 45–60 days. Cost efficiencies range from 20–35% compared to European or North American manufacturers due to lower labor and operational overheads, while maintaining compliance with international performance benchmarks.

How to Choose Copper Rod Continuous Casting Machine Distributors?

Evaluate suppliers using the following technical and operational criteria:

Technical Compliance & Process Capability

Confirm adherence to ISO 9001 quality management standards as a baseline. For oxygen-free copper or high-conductivity applications, verify compatibility with ASTM B49 and IEC 60468 specifications. Demand documentation on cooling system design, casting speed control (typically 1.5–3 m/min), and induction furnace frequency tuning (150–1000 Hz range).

Production Infrastructure Assessment

Assess core capabilities through verifiable metrics:

- Minimum factory area of 3,000m² for full-line assembly capacity

- In-house engineering teams supporting customization of rod diameter (8–20 mm standard), alloy composition, and automation level

- Integrated testing protocols including ultrasonic flaw detection and tensile strength validation

Cross-reference online transaction data with on-time delivery rates exceeding 97% to validate operational reliability.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services until site commissioning is confirmed. Prioritize suppliers offering remote diagnostics, operator training, and spare parts inventories. Review reorder rates as an indicator of post-installation satisfaction—suppliers with rates above 40% demonstrate consistent service and technical performance.

What Are the Leading Copper Rod Continuous Casting Machine Distributors?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Jiaxing Jicheng Machinery Co., Ltd. | Zhejiang, CN | Metal Casting Machinery (79), Wire Drawing Machines (31) | 100% | ≤3h | - | - | Color, material, size, logo, packaging, label, graphic |

| Henan Zhengyang Machinery Equipment Co., Ltd. | Henan, CN | Other Metal & Metallurgy Machinery (385) | 97% | ≤2h | 47% | US $1,600,000+ | Copper rod color, material, size, logo, packaging, label, yearly capacity, graphic |

| Luoyang Monte Intelligent Technology Co., Ltd. | Henan, CN | Metal Casting Machinery (16), Industrial Furnaces (26) | 100% | ≤2h | <15% | US $40,000+ | Color, material, size, logo, packaging, label, graphic |

| Luo Yang Hongteng Electrical Equipment Co., Ltd. | Henan, CN | Metal Casting Machinery (listed), Conveyor systems | 100% | ≤3h | 87% | US $630,000+ | Conveyor, zama, color, iron weight, packaging, label, capacity, material, size, design, cooling width, copper logo, plug, moulds, graphic, zinc |

| Foshan Fanshun Machinery Co., Ltd. | Guangdong, CN | Metal Product Processing Line (80), Industrial Furnaces (26) | 100% | ≤2h | - | - | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Luo Yang Hongteng leads in customer retention with an 87% reorder rate, indicating strong after-sales performance and system reliability. Henan Zhengyang stands out in scale, backed by over US $1.6 million in verified revenue and broad product availability. While several suppliers report 100% on-time delivery, reorder rates below 15%—as seen with Luoyang Monte—suggest potential gaps in long-term support despite timely shipment. Jiaxing Jicheng and Foshan Fanshun offer solid technical foundations but limited financial transparency. Buyers seeking customized solutions should prioritize vendors with documented R&D input and comprehensive parameter flexibility, particularly in alloy processing and line integration.

FAQs

What certifications should copper rod casting machine suppliers have?

ISO 9001 is essential for quality system validation. For export to regulated markets, CE marking indicates compliance with EU safety directives. Suppliers serving high-purity sectors should provide test reports aligned with ASTM or IEC standards for electrical conductivity and mechanical properties.

What is the typical MOQ and pricing range?

Minimum order quantity is generally 1 set. Prices vary by configuration: compact horizontal units start at $6,000–$12,000, mid-range vertical systems range from $56,000–$100,000, while fully automated upward casting lines exceed $260,000 per set.

How long does production and shipping take?

Lead time averages 45–60 days for manufacturing and pre-shipment inspection. Sea freight adds 20–35 days depending on destination port. Air freight is not viable for complete lines due to size and weight constraints.

Can suppliers customize casting machines for specific alloys?

Yes, most distributors support customization for copper, brass, bronze, and aluminum alloys. Key adjustable parameters include crucible design, cooling jacket configuration, puller speed, and automation interface. Technical drawings and process flow diagrams should be reviewed prior to order confirmation.

Do suppliers provide installation and training?

Reputable suppliers offer remote commissioning support and instructional documentation. On-site installation and operator training may be available at additional cost. Clarify service terms—including travel expenses and duration—before contract finalization.