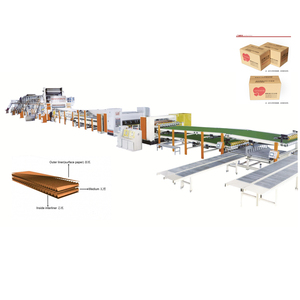

Corrugated Case Maker

CN

CN

CN

CN

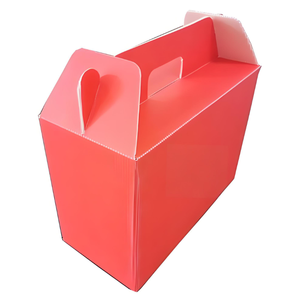

About corrugated case maker

Where to Find Corrugated Case Maker Suppliers?

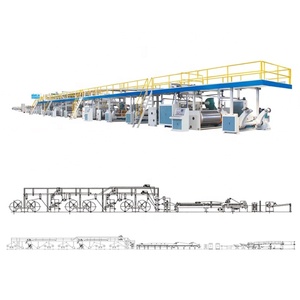

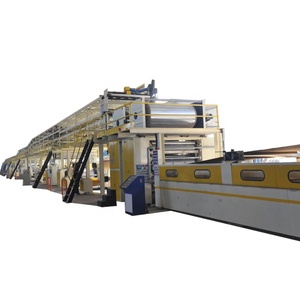

China remains the global epicenter for corrugated packaging manufacturing, with key production hubs concentrated in Guangdong and Anhui provinces. These regions host vertically integrated facilities that combine paperboard processing, die-cutting, printing, and assembly under one roof, enabling streamlined production of custom corrugated cases. Shenzhen-based suppliers benefit from proximity to major ports and advanced digital printing infrastructure, supporting rapid turnaround for e-commerce and retail clients. Meanwhile, Anhui’s industrial zone offers cost-efficient production due to lower labor and operational expenses, making it ideal for high-volume orders.

The clustering of raw material suppliers, converting machinery, and logistics networks within 50–100 km radii allows manufacturers to maintain lean inventories and reduce lead times. Most suppliers operate fully automated production lines capable of handling E-flute, B-flute, and double-wall corrugated board types. This integration supports MOQs as low as 100 units while maintaining competitive pricing, with standard lead times ranging from 7 to 15 days for sample batches and 15–25 days for full production runs.

How to Choose Corrugated Case Makers?

Selecting a reliable supplier requires rigorous evaluation across three core areas:

Production and Customization Capabilities

Verify access to in-house design, die-cutting, flexographic or digital printing, and folding/gluing equipment. Leading suppliers offer full customization including size engineering, UV coating, matte/gloss lamination, foil stamping, embossing, and window patching. Confirm compatibility with CMYK and Pantone color systems for brand consistency. Suppliers with dedicated R&D teams can support structural design optimization for durability and shipping efficiency.

Quality Assurance and Compliance

Prioritize suppliers adhering to internationally recognized quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates (≥96%) and third-party transaction verification are strong proxies for operational reliability. For food-grade or export-sensitive applications, ensure compliance with FDA, FSC, or RoHS standards where applicable. Request physical or digital samples to assess print accuracy, adhesive strength, and edge crush test (ECT) performance.

Transaction and Fulfillment Metrics

Evaluate response time (target ≤4 hours), reorder rate (indicative of customer satisfaction), and online transaction volume as indicators of service reliability. Use incremental ordering strategies—start with small batches to validate quality before scaling. Confirm packaging integrity measures such as reinforced corners, moisture-resistant coatings, and flat-pack folding designs for efficient shipping.

What Are the Best Corrugated Case Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Anhui Hengda New Materials Co., Ltd. | Plastic Boxes, Plastic Sheets | US $30,000+ | 100% | <15% | ≤2h | 300 pcs | $0.25–3.25 |

| Shenzhen Sinmenda Industry Co., Ltd. | Paper Boxes, Plastic Boxes, Printing Services | US $610,000+ | 100% | 35% | ≤9h | 200 pcs | $0.01–0.80 |

| Shenzhen Mike Packaging Products Co., Ltd. | Custom Corrugated Mailer Boxes | US $60,000+ | 96% | 32% | ≤4h | 2 pcs | $0.01–1.85 |

| Shenzhen JDI Packaging Technology Co., Ltd. | Corrugated Boxes, Die-Cut Packaging | US $120,000+ | 100% | 20% | ≤2h | 2 pcs | $0.01–0.27 |

| Shanghai Zhize Printing Technology Co., Ltd. | Printed Folding Boxes, Corrugated Cases | US $780,000+ | 100% | 36% | ≤8h | 500 pcs | $0.10–0.21 |

Performance Analysis

Shanghai Zhize Printing leads in customer retention with a 36% reorder rate and high transaction volume, indicating strong satisfaction in print quality and order execution. Shenzhen Mike Packaging stands out for flexibility, offering MOQs as low as two pieces—ideal for startups and product testing. Anhui Hengda and Shenzhen JDI achieve perfect on-time delivery records with sub-2-hour response times, reflecting robust internal coordination. However, lower reorder rates suggest room for improvement in post-sale engagement or long-term value proposition. Suppliers like Sinmenda and Zhize demonstrate balanced capabilities in both paper and plastic packaging, enhancing cross-category sourcing potential.

FAQs

What materials do corrugated case makers typically use?

Standard substrates include E-flute, B-flute, and double-wall corrugated fiberboard made from kraft paper or recycled paperboard. Some suppliers integrate EVA, PVC windows, or foam inserts for protective packaging. Water-based, eco-friendly adhesives are standard in modern production.

How low can MOQs go for custom corrugated cases?

MOQs vary by complexity and printing method. Digital print jobs can start at 100–200 units, while offset or flexo printing may require 500+ units. A few suppliers, such as Shenzhen Mike and JDI Packaging, offer sample-ready MOQs of just 2–100 pieces for basic designs.

What is the average lead time for custom orders?

Sample production typically takes 5–10 days. Full batch lead times range from 12 to 20 days, depending on order size, finishing requirements, and shipping method. Express air freight adds 3–7 days for international delivery.

Do suppliers provide design assistance?

Yes, most suppliers offer free structural design services using CAD or Adobe Illustrator templates. They can assist with box style selection (e.g., slotted, telescope, tray), dimensional planning, and load testing simulations.

Can corrugated cases be branded with logos and colors?

All listed suppliers support full-color CMYK printing, spot colors, and premium finishes including UV varnish, hot stamping, embossing, and holographic effects. Brand-specific Pantone matching is available upon request.