Corrugated Machine Maker

1/26

1/26

1/12

1/12

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/25

1/25

1/20

1/20

1/14

1/14

0

0

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/31

1/31

0

0

1/3

1/3

1/3

1/3

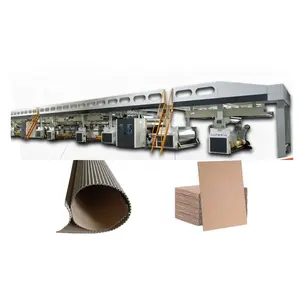

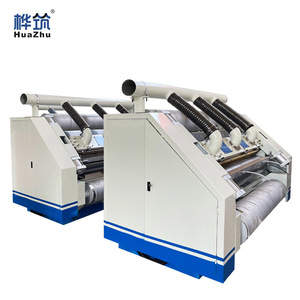

About corrugated machine maker

Where to Find Corrugated Machine Makers?

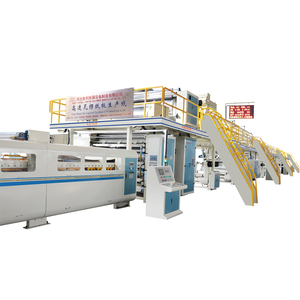

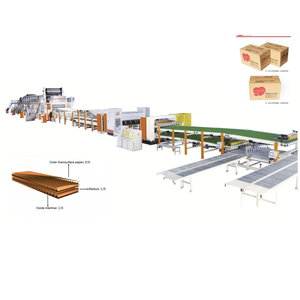

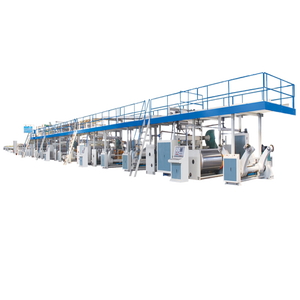

China remains the dominant hub for corrugated machine manufacturing, with key production clusters concentrated in Hebei and Guangdong provinces. These regions host vertically integrated facilities specializing in complete corrugated board production lines, from single-facer units to full automatic 7-ply systems. Hebei-based suppliers benefit from proximity to raw material sources and a mature ecosystem of paper machinery component manufacturers, enabling cost efficiencies of 20–30% compared to Western producers. Foshan in Guangdong has emerged as a center for refurbished and used industrial packaging equipment, offering high-performance second-hand lines at reduced capital investment.

The industrial clusters support rapid scalability through localized supply chains—fabrication, CNC machining, and assembly operations are typically co-located within 50 km. This integration allows lead times of 30–60 days for new machinery and immediate availability for pre-owned systems. Buyers gain access to diverse configurations, including 3-ply, 5-ply, and 7-ply lines capable of producing carton board at speeds up to 200 meters per minute. Customization options span die-cutting modules, printing sections, gluing mechanisms, and automated control systems, facilitating tailored solutions for regional market demands.

How to Choose Corrugated Machine Makers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer machines compliant with international safety and performance standards. While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery (100% reported by multiple suppliers) suggests adherence to structured quality management systems. For export markets, CE marking or equivalent regulatory compliance should be verified prior to procurement. Evaluate machine specifications such as ply capacity (3/5/7-layer), speed ratings, power consumption, and automation level.

Production Infrastructure Assessment

Key indicators of manufacturing robustness include:

- Ownership of end-to-end production lines indicating vertical integration

- Capacity to deliver both individual components (e.g., single facers) and turnkey production lines

- In-house engineering teams supporting customization of material feed, cutting length, color coding, and labeling systems

Cross-reference product listings with response times (≤3 hours observed in top-tier suppliers) and reorder rates as proxies for customer satisfaction and service reliability.

Procurement Risk Mitigation

Utilize secure payment frameworks such as third-party escrow services to align financial release with equipment verification. Prioritize suppliers with transparent transaction histories and documented after-sales support. Pre-shipment inspection protocols are critical—request factory acceptance tests (FAT) via video audit or on-site visits, particularly when sourcing high-value lines exceeding $200,000.

What Are the Best Corrugated Machine Makers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Cangzhou Lighten Import & Export Trading Co., Ltd. | Hebei, CN | Full-automatic 3–7-ply lines, single facer machines | $10,888–$200,000 | 1 set | 100% | ≤3h | 85% | $120,000+ |

| Cangzhou Quanheng Imp & Exp Trade Co., Ltd. | Hebei, CN | Automatic 3–7-ply lines, used equipment | $65,000–$300,000 | 1 set | 100% | ≤3h | <15% | $640,000+ |

| Hebei Shengli Paper Chest Equipment Manufacturing Co., Ltd. | Hebei, CN | Single-layer machines, high-speed 5-ply systems | $2,500–$500,000 | 1 piece/set | 100% | ≤11h | - | - |

| Foshan Sanniu Packaging Machinery Co., Ltd. | Guangdong, CN | Used/refurbished 2–7-layer production lines | $7,600–$455,000 | 1 set | 100% | ≤7h | - | - |

| Dongguang Luyuan Carton Machinery Manufacture Co., Ltd. | Hebei, CN | High-speed automatic 3–7-ply lines | $80,000–$350,000 | 1 set | 100% | ≤3h | - | - |

Performance Analysis

Cangzhou Lighten stands out with an 85% reorder rate—indicating strong post-sale performance and client retention—coupled with rapid ≤3-hour response times. Despite lower online revenue visibility, Dongguang Luyuan and Cangzhou Quanheng list extensive high-value product ranges, suggesting established export channels. Foshan Sanniu specializes in the secondary market, offering refurbished lines priced between $7,600 and $455,000, ideal for budget-conscious buyers seeking operational readiness. Hebei-based manufacturers dominate new machine supply, with pricing stratified by automation level and ply capacity. Suppliers reporting response times under 3 hours demonstrate superior communication infrastructure, a critical factor in managing cross-border technical coordination.

FAQs

How to verify corrugated machine maker reliability?

Validate operational credibility through direct assessment of facility ownership, production line integration, and order fulfillment history. Request documentation of machine testing procedures, component sourcing policies, and warranty terms. Analyze verifiable transaction metrics such as on-time delivery records and customer reorders rather than relying solely on self-reported claims.

What is the typical lead time for corrugated machinery?

New production lines generally require 45–60 days for manufacturing and testing. Standard single-component machines may ship within 30 days. Used or refurbished systems often have immediate availability, reducing deployment timelines significantly.

Can suppliers customize corrugated machines?

Yes, most suppliers offer configuration options for material type, sheet size, printing stations, die-cutting patterns, and control software interfaces. Customization scope varies—top-tier suppliers provide engineering support for integrating specific color schemes, labeling systems, and automation protocols into turnkey lines.

What are common MOQs for corrugated machines?

Minimum order quantities are typically set at 1 set or 1 piece, allowing flexibility for small-scale operators and pilot installations. No volume discounts are indicated in public listings, but bulk purchases may allow negotiation leverage on installation, training, or spare parts inclusion.

Do manufacturers provide technical support and installation?

While not explicitly detailed in supplier tags, industry-standard practice includes remote guidance and optional on-site commissioning. Buyers should confirm availability of English-speaking technicians, operational manuals, and spare parts inventories before finalizing contracts.