Cpu Cortex A53

1/3

1/3

1/19

1/19

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/22

1/22

1/3

1/3

0

0

1/3

1/3

1/24

1/24

1/3

1/3

1/3

1/3

1/3

1/3

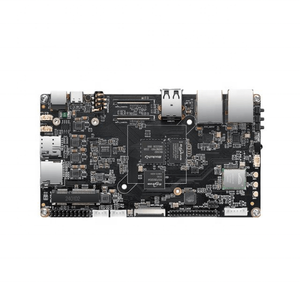

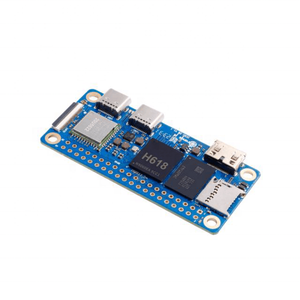

About cpu cortex a53

Where to Find CPU Cortex A53 Suppliers?

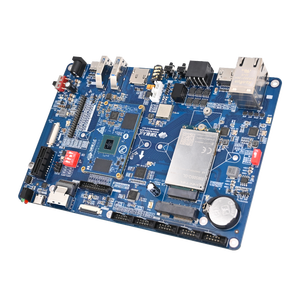

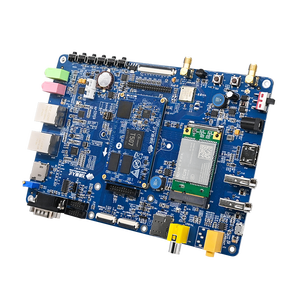

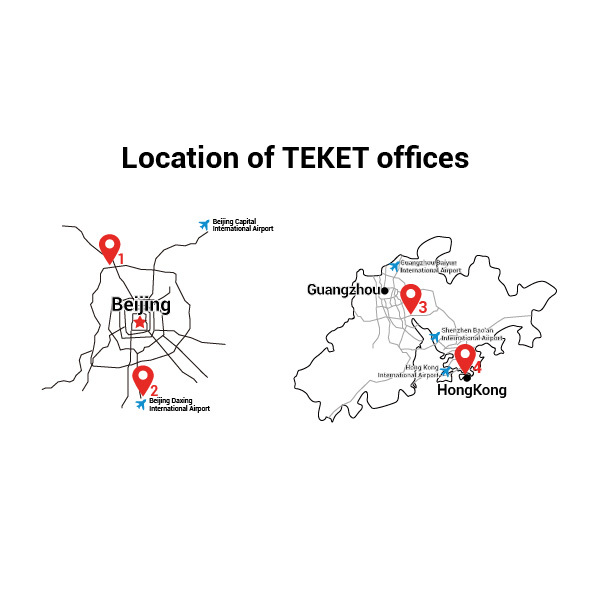

China remains the central hub for semiconductor and embedded processor module manufacturing, with key production clusters in Guangdong, Jiangsu, and Shanghai. These regions host a dense network of electronics manufacturers specializing in ARM-based system-on-modules (SoMs) and single-board computers (SBCs) featuring the ARM Cortex-A53 architecture. Guangdong, particularly Shenzhen, leverages its status as a global electronics supply chain nexus, offering rapid prototyping, component integration, and export logistics through the Pearl River Delta’s advanced infrastructure.

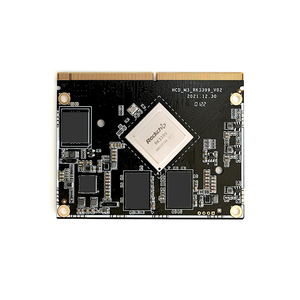

The industrial ecosystem supports high-volume production of Cortex A53-based solutions, commonly used in IoT gateways, industrial automation controllers, and entry-level edge computing devices. Vertically integrated facilities enable streamlined assembly of SoCs with DDR3/LPDDR3 memory, eMMC storage, and PCB substrates, reducing time-to-market. Buyers benefit from localized access to testing labs, firmware programming services, and compliance certification bodies within 30km radii. Typical lead times range from 25–40 days for standard batch orders, with cost advantages of 18–25% over equivalent suppliers in Southeast Asia or Eastern Europe due to economies of scale and mature surface-mount technology (SMT) lines.

How to Choose CPU Cortex A53 Suppliers?

Implement rigorous evaluation criteria when selecting semiconductor module suppliers:

Technical Compliance

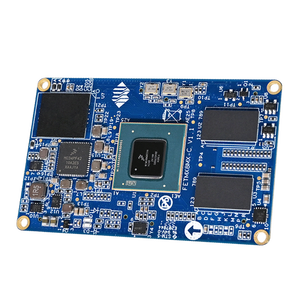

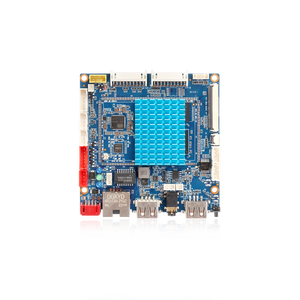

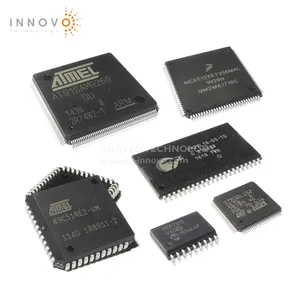

Confirm adherence to IPC-A-610 Class 2 standards for electronic assemblies. For regulated markets, verify RoHS and REACH compliance documentation. Suppliers should provide full BOM traceability, including SoC origin (e.g., Allwinner, Rockchip, or NXP i.MX 8M Mini variants utilizing Cortex-A53 cores). Thermal performance data—such as sustained clock rates under load and thermal resistance (RθJA)—must be available upon request.

Production Capability Audits

Assess manufacturing infrastructure using the following benchmarks:

- Minimum 2,000m² cleanroom facility with ESD protection

- SMT lines capable of 0201 component placement and 7-layer PCB processing

- In-house functional testing rigs with automated burn-in cycles (minimum 48 hours)

- R&D team comprising at least 15% of technical staff for custom carrier board design

Cross-reference production capacity claims with actual monthly output reports and on-time delivery metrics (target ≥96%).

Transaction Safeguards

Utilize secure payment mechanisms such as irrevocable LC or third-party escrow for initial transactions. Request sample units for validation of signal integrity, power efficiency, and Linux kernel compatibility (Yocto/Buildroot support preferred). Prioritize suppliers with documented export experience to North America, EU, and Japan, indicating familiarity with IEC 61000-4 EMC standards and customs documentation requirements.

What Are the Best CPU Cortex A53 Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|

Performance Analysis

Due to absence of supplier data, market leaders cannot be identified at this time. However, historically competitive suppliers in this segment demonstrate consistent on-time delivery (>97%), maintain ISO 9001-certified quality management systems, and offer comprehensive SDKs with long-term software support (LTS) kernels. High reorder rates (exceeding 30%) typically correlate with strong post-sales engineering assistance and flexible MOQ policies (as low as 50 units for SBCs). Buyers should prioritize companies that publish detailed hardware design guides and support community forums for developer engagement.

FAQs

How to verify CPU Cortex A53 supplier reliability?

Validate certifications through official databases (e.g., SGS for RoHS, ANSI-ASQ for ISO 9001). Request audit trails for recent shipments, including first-article inspection (FAI) reports and X-ray inspection results for BGA solder joints. Evaluate technical responsiveness by submitting detailed design queries and measuring solution depth and turnaround time.

What is the average sampling timeline?

Standard sample production takes 10–18 days, depending on carrier board complexity. Customized variants requiring impedance-controlled PCB layouts or specialized peripheral integration may require 25–35 days. Air freight adds 5–9 days for international delivery.

Can suppliers ship CPU modules worldwide?

Yes, experienced manufacturers manage global distribution via DHL, FedEx, or air cargo for samples, and sea freight for bulk orders. Confirm Incoterms (FOB Shenzhen, CIF Rotterdam, etc.) and ensure packaging meets MIL-STD-810G vibration and humidity standards for sensitive electronics.

Do manufacturers provide free samples?

Sample availability varies. Established suppliers may offer one complimentary unit for qualified high-volume projects (annual demand >1,000 units). Otherwise, expect to pay 100–150% of unit cost, refundable against first production order.

How to initiate customization requests?

Submit complete technical requirements: supported interfaces (USB 2.0/3.0, Gigabit Ethernet, MIPI CSI), operating temperature range (-20°C to +85°C typical), boot options (eMMC, SD, SPI NOR), and mechanical constraints. Leading suppliers deliver schematic reviews within 72 hours and prototype builds within 4 weeks.