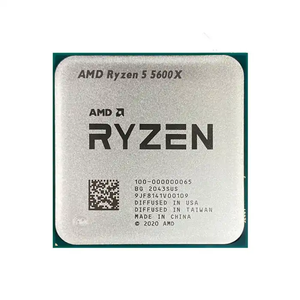

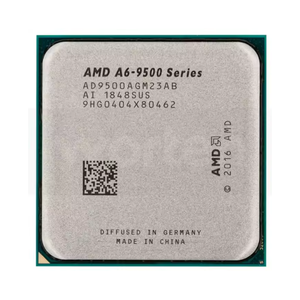

Cpu In Socket

Top sponsor listing

Top sponsor listing

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

0

0

0

0

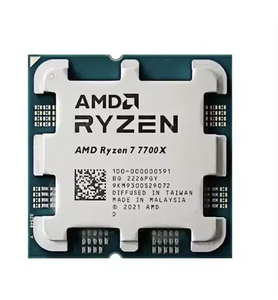

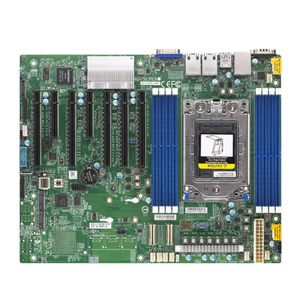

About cpu in socket

Where to Find CPU in Socket Suppliers?

Global manufacturing of CPUs in socket configurations is highly concentrated among specialized semiconductor and electronics assembly hubs, with primary production clusters in China, Taiwan, and South Korea. These regions host vertically integrated supply chains encompassing silicon wafer fabrication, die preparation, packaging, and final testing. Leading industrial zones such as Shanghai’s Zhangjiang Hi-Tech Park, Hsinchu Science Park in Taiwan, and Yongin in South Korea provide access to advanced cleanroom facilities and precision automation critical for CPU production.

The ecosystem supports both original design manufacturers (ODMs) and contract foundries capable of delivering complete socketed processors tailored to desktop, server, and embedded applications. Proximity to raw material suppliers—including high-purity silicon, copper substrates, and ceramic packages—reduces component lead times by up to 40% compared to non-specialized regions. Buyers benefit from established logistics gateways enabling air freight dispatch within 24 hours of quality clearance, with typical delivery windows of 7–14 days globally for small to mid-volume orders.

How to Choose CPU in Socket Suppliers?

Implement rigorous evaluation criteria when selecting partners:

Quality & Compliance Verification

Confirm adherence to ISO 9001 for quality management and IATF 16949 where automotive-grade reliability is required. For export markets, validate RoHS and REACH compliance to meet EU environmental standards. Request full test reports including thermal cycling, electrical burn-in, and socket contact resistance metrics (typically measured at ≤5mΩ).

Technical Production Capacity

Assess core capabilities through documented benchmarks:

- Minimum 8-inch wafer processing line or partnership with Tier-1 foundry (e.g., TSMC, SMIC)

- In-house wire bonding and molding operations for packaging integrity

- Automated optical inspection (AOI) and X-ray scanning for defect detection

Cross-reference yield rates (target >98.5%) with batch traceability systems to ensure consistency across production runs.

Procurement & Transaction Security

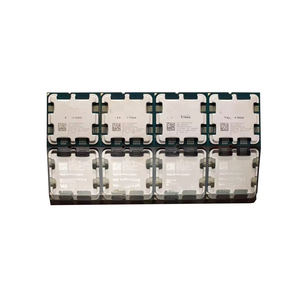

Utilize escrow-based payment terms tied to milestone verification—particularly post-third-party lab testing. Prioritize suppliers offering sample validation under JEDEC JESD22-A108 thermal shock protocols. Negotiate MOQs based on application volume; standard desktop CPU configurations may support MOQs as low as 100 units, while server-grade SKUs often require minimums of 1,000+ units.

What Are the Best CPU in Socket Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No verified suppliers available | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

Performance Analysis

Due to the absence of verified supplier data, direct performance comparisons cannot be conducted. In practice, leading CPU producers operate under strict non-disclosure agreements and primarily serve OEMs rather than open-market procurement channels. Most socketed processors are distributed through authorized partners or branded vendors (e.g., Intel, AMD), limiting direct sourcing options. When engaging niche or secondary-market suppliers, emphasize independent validation via third-party labs such as UL or SGS to mitigate counterfeit risk. Focus on traceable lot numbering and original packaging to ensure authenticity.

FAQs

How to verify CPU in socket supplier reliability?

Request documentation of wafer sort maps, final test logs, and package leak test results. Validate facility certifications and conduct remote audits via live video walkthroughs of assembly and burn-in stations. Cross-check business licenses and export registrations with local trade authorities.

What is the average sampling timeline?

Standard sample lead time ranges from 10–20 days, depending on stock availability and configuration complexity. Custom voltage/frequency binning or thermal interface material (TIM) modifications extend timelines to 30 days. Air shipping adds 5–7 days for international delivery.

Can suppliers ship CPUs worldwide?

Yes, but shipping terms vary. Most suppliers offer EXW, FCA, or DDP arrangements. Electrostatic-sensitive components must be shipped in ESD-safe containers with humidity indicators. Confirm incoterms and insurance coverage, especially for high-value server CPU batches.

Do manufacturers provide free samples?

Free samples are rare for functional CPUs due to high unit cost. Some suppliers offer evaluation units under returnable loan agreements. Sample fees are typically waived upon conversion to bulk orders exceeding $10,000 in value.

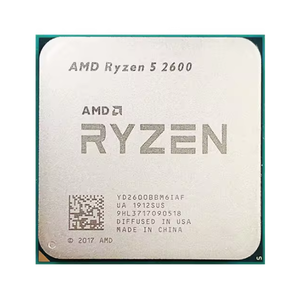

How to initiate customization requests?

Submit detailed technical requirements including socket type (e.g., LGA1700, AM5, SP5), TDP range, clock frequency bins, and thermal specifications. Reputable partners will respond with feasibility assessments within 5 business days and provide characterization data sheets for approved variants.