Creating Own Clothing Line

HK

HK

About creating own clothing line

Where to Find Clothing Line Manufacturing Suppliers?

China remains a dominant force in apparel manufacturing, with key production clusters in Guangdong, Fujian, and Anhui provinces enabling scalable, cost-efficient garment production. Dongguan and Xiamen serve as major hubs for custom clothing manufacturers, offering vertically integrated supply chains that streamline fabric sourcing, cutting, sewing, and finishing processes. These regions benefit from concentrated textile ecosystems—reducing lead times by 20–30% compared to decentralized production models.

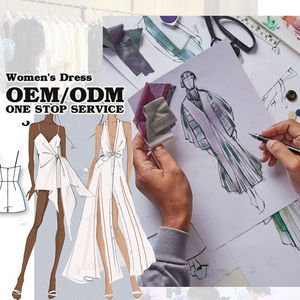

Suppliers in these industrial zones specialize in both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing), supporting startups and established brands in launching private-label collections. Facilities typically operate under ISO-compliant quality management systems, with many offering digital printing, embroidery, washing treatments, and mockup development. Buyers gain access to low minimum order quantities (MOQs), often starting at 30–50 pieces per design, alongside rapid prototyping capabilities for market testing.

How to Choose Clothing Line Manufacturing Suppliers?

Selecting the right partner requires due diligence across technical, operational, and transactional dimensions:

Design & Customization Capability

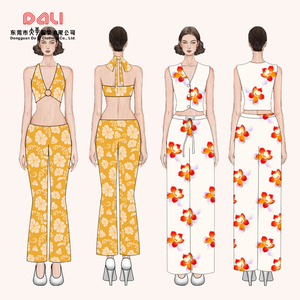

Confirm suppliers offer end-to-end design services, including pattern making, fabric sourcing, and sample development. Evaluate customization depth: advanced providers support material selection (cotton, french terry, jacquard, corduroy), digital/screen printing, embroidery, distressing, and wash effects. Request digital mockups or physical samples before committing to bulk orders.

Production Capacity & Compliance

Assess infrastructure maturity through verifiable metrics:

- Facility size and workforce scale indicating volume handling capability

- In-house design teams for agile product development

- Compliance with international quality standards (e.g., ISO 9001)

- On-time delivery performance exceeding 95%

Suppliers with dedicated R&D units can better accommodate complex designs and iterative revisions, reducing time-to-market.

Procurement Safeguards

Prioritize suppliers with transparent transaction histories and responsive communication (target response time ≤4 hours). Utilize secure payment mechanisms and verify order fulfillment records, including reorder rates as an indicator of client satisfaction. Conduct video audits of production lines to validate claims about capacity and workflow control.

What Are the Best Clothing Line Manufacturing Suppliers?

| Company Name | Verification Type | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Hefei Romanticism Import And Export Co., Ltd. | Multispecialty Supplier | US $30,000+ | 100% | 27% | ≤3h | 30 pcs | $10.50–16.50 |

| Xiamen Richker Information Technology Co., Ltd. | Custom Manufacturer | US $120,000+ | 100% | 31% | ≤3h | 50–60 pcs | $4–30 |

| Dongguan Xiangrui Clothing Co., Ltd. | Custom Manufacturer | US $270,000+ | 100% | 44% | ≤4h | 50 pcs | $10.10–19.90 |

| Dongguan Yili Fang Clothing Co., Ltd. | Custom Manufacturer | US $10,000+ | 56% | <15% | ≤1h | 30–50 pcs | $4–13.64 |

| Aoxi Fashion Garment Limited Company (Dongguan) | Custom Manufacturer | US $540,000+ | 99% | 48% | ≤4h | 50–100 pcs | $7.80–17.70 |

Performance Analysis

Aoxi Fashion Garment demonstrates strong client retention (48% reorder rate) and high-volume export experience (US $540,000+ online revenue), making it a reliable choice for growing brands. Dongguan Xiangrui offers extensive customization options—from jacquard weaving to distressed finishes—and maintains perfect on-time delivery, ideal for time-sensitive launches. Hefei Romanticism stands out for ultra-low MOQs (30 pieces), beneficial for startups testing initial designs. While Dongguan Yili Fang provides competitive pricing and fast responses, its 56% on-time delivery rate indicates potential fulfillment risks. Buyers should prioritize suppliers with balanced metrics: high delivery reliability, proven customization depth, and transparent communication.

FAQs

How to verify clothing manufacturer reliability?

Cross-check supplier claims with verifiable data: request facility videos, audit reports, and customer references. Analyze on-time delivery rates, reorder frequency, and response consistency. Confirm compliance with quality management standards and review sample craftsmanship before scaling orders.

What is the typical sampling timeline for custom garments?

Sample production generally takes 7–14 days, depending on design complexity and material availability. Digital mockups may be delivered within 48 hours. Shipping via express courier adds 3–7 days internationally.

Can suppliers handle global shipping and customs documentation?

Yes, experienced exporters manage international logistics, including FOB and CIF terms. Ensure suppliers provide full documentation (commercial invoice, packing list, bill of lading) and comply with destination-country labeling and textile regulations.

Do clothing manufacturers offer free samples?

Policies vary. Some suppliers refund sample costs upon bulk order placement, while others charge a nominal fee covering materials and labor. Expect fees to range between $50–$200 per style, depending on construction complexity.

How to initiate a private label clothing line with a manufacturer?

Begin by submitting detailed specifications: target garment type, preferred fabrics, sizing charts, logo placement, and packaging requirements. Reputable manufacturers will provide tech packs, material swatches, and prototype timelines within 72 hours of inquiry.