Custom Apparel Maker

About custom apparel maker

Where to Find Custom Apparel Maker Suppliers?

China remains the global epicenter for custom apparel manufacturing, with concentrated production hubs in Guangdong and Fujian provinces driving efficiency and specialization. Dongguan and Guangzhou in Guangdong host a high density of vertically integrated garment factories equipped with in-house design, cutting, sewing, and finishing lines. These clusters benefit from mature textile ecosystems—proximity to fabric mills, dyeing facilities, and accessory suppliers reduces material lead times by 20–30% compared to offshore alternatives.

Suppliers in this region typically operate dedicated production lines for OEM/ODM orders, supporting low minimum order quantities (MOQs) starting at 50 pieces across most categories. The integration of digital printing, embroidery, and heat-transfer technologies enables rapid turnaround on branded apparel, while seamless construction and performance fabric processing cater to activewear demand. Average production cycles range from 15–30 days post-approval, with express options available for urgent runs.

How to Choose Custom Apparel Maker Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Production & Customization Capability

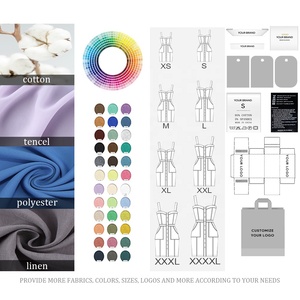

Confirm suppliers possess end-to-end control over the manufacturing process. Key indicators include ownership of cutting rooms, pattern-making units, and sample development teams. Prioritize vendors offering full customization: color, size grading, logo application (embroidery, screen print, sublimation), label packaging, and graphic design support. Suppliers with proprietary fabric sourcing or eco-friendly material access (e.g., organic cotton, recycled polyester) provide added value for sustainable collections.

Operational Performance Metrics

Evaluate reliability using verifiable benchmarks:

- On-time delivery rate ≥97%

- Response time ≤3 hours for initial inquiries

- Reorder rate above 30%, indicating customer retention

- Minimum monthly output capacity exceeding 10,000 units

Cross-reference these metrics with order volume history and online transaction data where available.

Quality Assurance & Transaction Security

While formal certifications like ISO 9001 are less commonly cited among mid-tier suppliers, consistent quality is demonstrated through repeat business and photo-verified product consistency. Utilize structured sampling protocols—request physical or digital mockups before bulk production. For financial protection, engage only suppliers offering secure transaction mechanisms and clear dispute resolution pathways.

What Are the Best Custom Apparel Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Dongguan Zhongyi Clothing Co., Ltd. | Dongguan, CN | Custom Manufacturer | US $370,000+ | 99% | ≤2h | 39% | 50 pcs | Color, material, size, logo, packaging, label, graphic |

| Guangzhou Honghaotian Garments Co., Ltd. | Guangzhou, CN | Custom Manufacturer | US $30,000+ | 97% | ≤2h | 20% | 50 pcs | Color, size, logo, packaging, label, graphic |

| Dongguan City Xishang Clothing Co., Ltd. | Dongguan, CN | Multispecialty Supplier | US $40,000+ | 85% | ≤2h | 38% | 50 pcs | Color, size, logo, packaging, label, graphic |

| Dongguan Humen Siyinghong Garment Manufactory | Dongguan, CN | Custom Manufacturer | US $1,500,000+ | 97% | ≤3h | 58% | 50 pcs | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Conceptcase Industrial Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | US $690,000+ | 99% | ≤3h | 28% | 1–51 pcs* | Seamless, color blocking, ribbed designs, high-end fabrics, spandex blends, reflective elements, mailer bags, heat transfer, embroidery, mockup services |

Performance Analysis

Dongguan Humen Siyinghong stands out with the highest reorder rate (58%) and substantial annual revenue (US $1.5M+), signaling strong client satisfaction despite slightly longer response windows. Shenzhen Conceptcase offers exceptional flexibility with MOQs as low as 1 piece on select items, making it ideal for startups and small brands testing designs. Dongguan Zhongyi and Shenzhen Conceptcase both achieve 99% on-time delivery, reflecting robust production planning. Notably, Shenzhen Conceptcase provides advanced technical capabilities including seamless knitting and performance fabric engineering, catering to premium activewear segments.

FAQs

How to verify a custom apparel maker’s reliability?

Assess on-time delivery history, reorder rate, and response speed as proxies for operational stability. Request reference samples or digital proofs to evaluate craftsmanship. Confirm direct control over production—factories with owned lines offer better accountability than trading companies.

What is the typical sampling timeline?

Standard sample production takes 7–12 days, depending on complexity. Digitally printed or embroidered samples may require an additional 3–5 days. Shipping via express courier adds 3–6 business days internationally.

Can suppliers accommodate small batch orders?

Yes, many suppliers support low MOQs. Standard minimums are 50 pieces, but some—like Shenzhen Conceptcase—offer micro-batches starting at 1–5 pieces for certain styles, enabling cost-effective prototyping and limited releases.

Do manufacturers provide free samples?

Policies vary. Some suppliers refund sample costs upon bulk order placement, while others charge a nominal fee covering materials and labor. Free samples are rarely offered without commitment.

How to initiate customization requests?

Submit detailed specifications including garment type, base fabric, color palette, size chart, logo format (vector preferred), and application method. Reputable suppliers will return tech packs and digital mockups within 48–72 hours for approval prior to sampling.