Custom Automated Machinery

Top sponsor listing

Top sponsor listing

CN

CN

About custom automated machinery

Where to Find Custom Automated Machinery Suppliers?

China remains the global epicenter for custom automated machinery manufacturing, with key industrial clusters in Guangdong, Shanghai, and Jiangsu provinces driving innovation and production efficiency. Dongguan and Foshan in Guangdong province host specialized ecosystems focused on automation integration and packaging systems, supported by mature supply chains for servo motors, sensors, and control units. Shanghai’s precision engineering sector emphasizes high-tolerance CNC machining and turnkey automation solutions, leveraging proximity to R&D centers and export hubs.

These regions offer vertically integrated production networks—spanning sheet metal fabrication, mold development, electronics assembly, and final system integration—enabling rapid prototyping and scalable deployment. Buyers benefit from localized component sourcing, reducing lead times by 20–30% compared to offshore alternatives. Typical advantages include MOQ flexibility (from single units to full production lines), lead times of 30–60 days for customized systems, and cost savings of 25–40% due to optimized labor and logistics infrastructure.

How to Choose Custom Automated Machinery Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capabilities

Confirm in-house design and engineering resources capable of handling PLC programming, mechanical integration, and electrical controls. Prioritize suppliers offering customization in material selection, color coding, labeling, and functional modules. Evidence of CAD/CAM modeling, 3D simulation, and prototype validation should be verifiable through project portfolios or facility tours.

Quality Management Systems

ISO 9001 certification is a baseline indicator of process consistency. For international compliance, verify adherence to CE standards for electrical safety and machine directives. Review documentation on material traceability, welding integrity, and performance testing—especially for critical applications in food, pharmaceuticals, or hazardous environments.

Production Infrastructure Assessment

Evaluate core capabilities including:

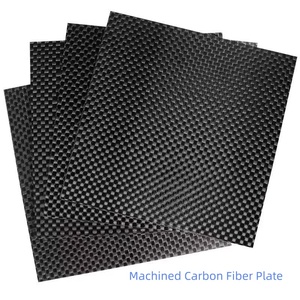

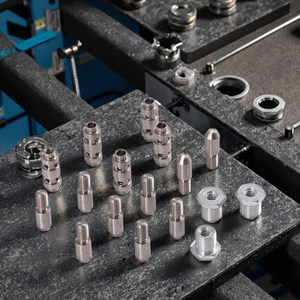

- CNC machining, sheet metal fabrication, casting, and molding services

- Dedicated automation assembly lines with modular design frameworks

- Integration of IoT-enabled monitoring and predictive maintenance features

Cross-reference online revenue indicators and order fulfillment metrics with response time and on-time delivery rates to assess operational stability.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services that release funds upon successful inspection. Request sample units for functional benchmarking prior to full-scale procurement. Analyze reorder rates as a proxy for customer satisfaction—rates below 20% may indicate inconsistent quality or post-sale support limitations.

What Are the Best Custom Automated Machinery Suppliers?

| Company Name | Location | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Shanghai Fangyou Precision Machinery Co., Ltd. | Shanghai, CN | Machining Services, Sheet Metal Fabrication, Moulds, Casting, Electronics Enclosures | Not specified | US $9,000+ | 100% | ≤1h | <15% | Not specified |

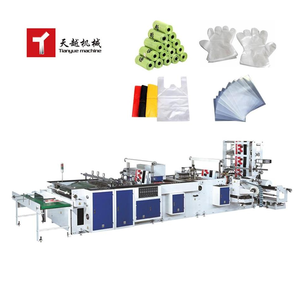

| Dongguan BanMo Machinery Co., Ltd. | Dongguan, CN | Pouch Machines, Bottled Liquid Fillers, Capping Systems | Color, material, size, logo, packaging, label, graphic | US $370,000+ | 99% | ≤2h | <15% | Multispecialty Supplier |

| Dongguan Ronghang Hardware Mould Co., Ltd. | Dongguan, CN | CNC Machining Parts, Precision Milling/Turning | Material-specific customization (stainless steel, aluminum, titanium) | US $360,000+ | 93% | ≤2h | 38% | Custom Manufacturer |

| Shanghai Shenhu Packaging Machinery Equipment Co., Ltd. | Shanghai, CN | Filling Machines, Packaging Lines, Sealing & Labeling Systems | Limited public detail | US $90,000+ | 80% | ≤4h | 20% | Not specified |

| Foshan Land Packaging Machinery Co., Ltd. | Foshan, CN | Automated Filling, Capping, Labeling, Wrapping Systems | Configurable pump types, volume settings, container compatibility | US $700,000+ | 93% | ≤3h | 25% | Not specified |

Performance Analysis

Foshan Land leads in scale and output, evidenced by the highest reported online revenue (US $700,000+) and robust 93% on-time delivery, making it suitable for large-volume automation deployments. Dongguan BanMo stands out for comprehensive customization options across aesthetics and functionality, paired with strong reliability (99% on-time delivery). Shanghai Fangyou achieves perfect punctuality (100%) and fastest response times (≤1h), ideal for urgent or iterative design projects despite lower revenue volume. Dongguan Ronghang’s elevated reorder rate (38%) suggests strong client retention, likely driven by consistent part quality in CNC-intensive applications. Shanghai Shenhu, while technically capable, shows lower delivery performance (80%), indicating potential bottlenecks in complex system integration.

FAQs

How to verify custom automated machinery supplier reliability?

Validate certifications (ISO 9001, CE) through official registries. Request documented quality control procedures, material test reports, and video evidence of assembly processes. Assess responsiveness and technical clarity during inquiry stages as proxies for long-term communication efficacy.

What is the typical lead time for customized automation systems?

Standard builds require 30–45 days after design approval. Complex integrations involving multi-stage filling, vision inspection, or robotic arms may extend to 60 days. Prototypes are typically delivered within 3–4 weeks for validation.

Are samples available before bulk ordering?

Most suppliers offer functional prototypes or sample machines for testing. Costs vary based on complexity—expect partial reimbursement upon contract signing. Sample fees often cover 30–50% of unit production expenses for highly engineered systems.

Can suppliers handle global shipping and installation?

Yes, experienced manufacturers manage international logistics via sea freight (FOB/CIF terms) and provide remote commissioning support. On-site installation and training may incur additional charges but are commonly available upon request.

What customization levels are typically offered?

Suppliers generally support modifications in physical dimensions, material grades (e.g., stainless steel 304/316), control interfaces (HMI languages, SCADA integration), and branding elements. Advanced configurations include variable speed drives, anti-corrosion coatings, and sterile design for regulated industries.