Custom Built Machinery

Top sponsor listing

Top sponsor listing

About custom built machinery

Where to Find Custom Built Machinery Suppliers?

China remains a global hub for custom built machinery manufacturing, with key production clusters in Shanghai, Shenzhen, Zhejiang, and Fujian provinces. These regions host vertically integrated facilities specializing in precision engineering, CNC machining, and industrial fabrication services. Shanghai and Zhejiang are recognized for high-precision gear systems and automation components, while Shenzhen excels in die-casting and powder metallurgy applications. Xiamen’s coastal location supports heavy fabrication and large-scale structural assembly, benefiting from proximity to deep-water ports for efficient export logistics.

The concentration of technical expertise and supply chain infrastructure enables rapid prototyping and scalable production. Suppliers in these hubs typically operate within ecosystems that include material sourcing, tooling development, quality inspection, and international compliance management—all within compact geographic zones. This integration reduces lead times by 20–30% compared to decentralized manufacturing models and supports flexible order volumes, from single-piece prototypes to mass production runs exceeding 10,000 units monthly.

How to Choose Custom Built Machinery Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

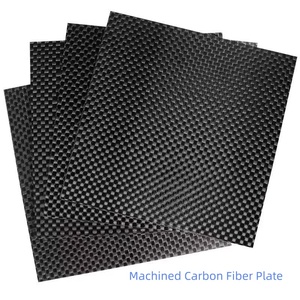

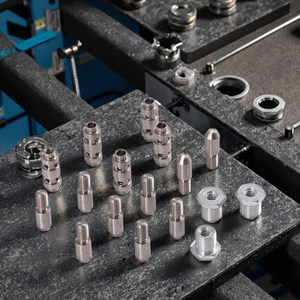

Verify suppliers have in-house machining, sheet metal fabrication, casting, or molding capabilities aligned with your component specifications. Key indicators include dedicated R&D teams, CAD/CAM design support, and experience with materials such as stainless steel, aluminum alloys, and engineered plastics. Prioritize companies offering OEM/ODM services with documented process control systems.

Quality Assurance Protocols

Confirm adherence to international standards through certifications such as ISO 9001. While not explicitly stated in all cases, consistent on-time delivery (≥80%) and low defect rates—implied by reorder rates above 25%—serve as proxies for quality reliability. For regulated industries, ensure compatibility with CE, RoHS, or other applicable directives during the design phase.

Customization Flexibility

Assess scope of customization options including:

- Material selection (metal type, grade, surface treatment)

- Dimensional tolerances (down to ±0.01mm in precision CNC work)

- Branding elements (logo engraving, packaging design, labeling)

- Functional integration (modular assemblies, sub-component matching)

Suppliers should provide technical feedback within 72 hours and offer 2D/3D design validation prior to sampling.

Transaction Reliability Indicators

Analyze performance metrics where available:

- On-time delivery rate ≥90%

- Response time ≤4 hours

- Reorder rate >15% (indicative of customer satisfaction)

- Minimum order quantity (MOQ) flexibility

Cross-reference digital revenue estimates (e.g., US $80,000+ annual online turnover) as a proxy for operational scale and market presence.

What Are the Best Custom Built Machinery Suppliers?

| Company Name | Location | Main Products (Listings) | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Shengyi Machinery Co., Ltd. | Zhejiang, CN | Spur Gears (411), Bevel Gears (176), Sheet Metal Fabrication (141) | Material, size, logo, packaging | 100% | 100% | ≤4h | US $370,000+ | 100 pieces |

| Shenzhen BSH Precision Die-Casting Products Co.,Ltd | Shenzhen, CN | CNC Machining, Forging, Steel Components | Color, material, size, powder metallurgy, labeling | 100% | 40% | ≤2h | US $80,000+ | 1 piece |

| Shanghai Fangyou Precision Machinery Co., Ltd. | Shanghai, CN | Machining Services (298), Sheet Metal (18), Moulds (9) | Color, material, size, logo, graphic | 100% | <15% | ≤1h | US $9,000+ | 1 piece |

| Xiamen Openex Mechanical Technology Limited | Xiamen, CN | Machining (160), Sheet Metal (117), Casting (44) | Structural design, material, fabrication method | 100% | - | ≤5h | - | 1 ton |

| Shenzhen Youkema Intelligent Technology Co., Ltd. | Shenzhen, CN | Machining Services (98) | Size, material, precision milling | 80% | 25% | ≤3h | US $20,000+ | 1 piece |

Performance Analysis

Zhejiang Shengyi stands out with a 100% reorder rate and extensive product range, indicating strong customer retention and technical versatility in gear manufacturing. Shenzhen BSH offers exceptional responsiveness (≤2h) and one-piece MOQs, ideal for prototyping and small-batch development. Shanghai Fangyou leads in communication speed (≤1h response) but has limited reorder activity, suggesting potential gaps in long-term client engagement despite full on-time delivery performance. Xiamen Openex specializes in heavy fabrication with ton-based minimums, suitable for large structural components. Shenzhen Youkema, while flexible in order size, shows an 80% on-time delivery rate, warranting closer scrutiny of production scheduling controls before high-volume commitments.

FAQs

What is the typical lead time for custom built machinery components?

Standard lead times range from 15–30 days for machined parts and sheet metal fabrications. Complex castings or forged components may require 35–50 days, depending on tooling requirements. Prototypes can be delivered in 7–14 days if design files are finalized.

Are samples available for testing?

Yes, most suppliers offer sample production. Costs vary based on complexity, with pricing starting from $0.01 per unit for simple components. Sample fees are often credited toward future bulk orders.

Can suppliers handle end-to-end project management?

Leading providers offer full ODM/OEM support, including design optimization, material sourcing, DFM analysis, and packaging customization. Video audits and virtual factory tours are available upon request to verify production workflows.

What are common payment terms?

Typical arrangements include 30% deposit with balance paid before shipment. Escrow services and trade assurance programs are widely used to mitigate risk. Letters of credit (L/C) are accepted by larger operations for container-sized orders.

Do suppliers support international shipping and customs clearance?

Yes, experienced exporters manage FOB, CIF, and DDP shipping terms. Documentation such as packing lists, commercial invoices, and material certificates are provided. Buyers should confirm import regulations for machinery components in their destination markets.