Custom Factory Automation

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About custom factory automation

Where to Find Custom Factory Automation Suppliers?

China remains the global epicenter for custom factory automation manufacturing, with key supplier clusters concentrated in Guangdong, Fujian, and Hunan provinces. These regions host vertically integrated industrial ecosystems that combine advanced R&D capabilities, precision engineering workshops, and rapid prototyping facilities. Guangdong—particularly Shenzhen and Dongguan—leads in electronics and medical device automation, leveraging proximity to semiconductor and PCB supply chains. Fujian’s Xiamen zone specializes in battery production systems, benefiting from localized lithium-ion component sourcing. Hunan has emerged as a hub for high-tonnage industrial assembly lines, supporting heavy machinery and automotive sectors.

The concentration of suppliers in these zones enables efficient collaboration between mechanical engineers, control system developers, and component manufacturers within 50km radii. This integration reduces design-to-deployment lead times by up to 30% compared to decentralized sourcing models. Buyers benefit from scalable production infrastructure capable of delivering single-unit prototypes or full-scale turnkey lines, with typical lead times ranging from 45–90 days depending on complexity. Localized supply chains also yield cost advantages, with production expenses averaging 20–35% below those of Western-based integrators.

How to Choose Custom Factory Automation Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm suppliers possess in-house engineering teams capable of handling non-standard designs and Industry 4.0 integration (e.g., IoT-enabled monitoring, PLC programming, SCADA systems). Prioritize companies with documented experience in your target application—such as electronic assembly, powder coating, or IV infusion manufacturing—to ensure process-specific expertise. Request 3D CAD models and control logic diagrams during the quoting phase to validate design competence.

Production Infrastructure Assessment

Evaluate core manufacturing assets:

- Minimum 2,000m² dedicated workshop space for complex system integration

- In-house machining capabilities (CNC, welding, laser cutting) to reduce subcontracting delays

- Dedicated testing bays for dry-run validation prior to shipment

Cross-reference facility size with order volume history and on-time delivery performance (target ≥95%) to assess scalability and reliability.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE, RoHS) are not uniformly listed in available data, insist on verifiable quality management processes including incoming material inspection, in-process QA checkpoints, and final system burn-in tests. Utilize secure payment mechanisms tied to milestone deliveries. Conduct pre-shipment inspections either independently or via third-party auditors to verify functionality against agreed specifications. Prototype sampling is strongly advised for first-time engagements, particularly for non-standard configurations.

What Are the Best Custom Factory Automation Suppliers?

| Company Name | Location | Main Products | Customization Scope | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier |

|---|---|---|---|---|---|---|---|

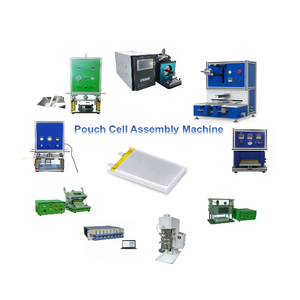

| Xiamen Tmax Battery Equipments Limited | Fujian, CN | Battery Equipment, Laboratory Heating, Metal Coating Machinery | Color, material, size, logo, packaging, graphic, labeling | 91% | ≤6h | <15% | US $110,000+ |

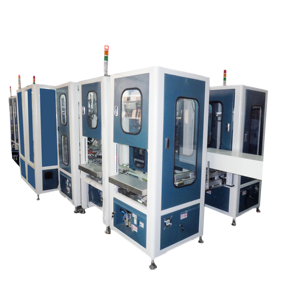

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Guangdong, CN | Electronic Assembly Lines, Medical Device Machines, Mask Production Systems | Full line customization, functional adaptation | 100% | ≤5h | 100% | US $2,000+ |

| Hunan Junjiesheng Automation Equipment Co., Ltd. | Hunan, CN | Speaker Production Lines, Gluing Machines, Electronics Processing Lines | Design and build to specification | 100% | ≤2h | - | - |

| Shenzhen Zeyu Intelligent Industrial Science Technology Co., Ltd. | Guangdong, CN | Automotive Fuse Lines, Gearbox Assembly, Non-Standard Automation Equipment | Non-standard machine design, modular integration | 100% | ≤2h | - | US $2,000+ |

| Guangdong Chuangzhi Intelligent Equipment Co., Ltd. | Guangdong, CN | Powder Coating Lines, Conveyor Systems, Air Conditioning Pipe Automation | Size, layout, integration, material handling | 100% | ≤1h | <15% | - |

Performance Analysis

Shenzhen Tianluo stands out with a 100% reorder rate and sub-5-hour response time, indicating strong customer satisfaction and operational responsiveness despite lower reported revenue. Hunan Junjiesheng and Shenzhen Zeyu demonstrate robust engineering agility with fully customizable solutions and rapid communication cycles (≤2h), making them suitable for iterative development projects. Guangdong Chuangzhi excels in conveyor and surface treatment automation, offering tightly controlled delivery performance. Xiamen Tmax serves niche battery and lab equipment markets with broad aesthetic and dimensional customization but exhibits a low reorder rate, suggesting potential gaps in post-sale support or long-term reliability. All top-tier suppliers offer minimum order quantities of one set, enabling pilot deployments without volume commitment.

FAQs

How to verify custom automation supplier capability?

Request access to project portfolios, client references, and video walkthroughs of completed installations. Verify in-house design and fabrication capacity through facility tours. Confirm whether software development (e.g., HMI interfaces, fault diagnostics) is performed internally or outsourced.

What is the typical lead time for customized automation systems?

Standard lead times range from 45 to 90 days post-design approval. Simpler systems (e.g., stacking robots, basic conveyors) may ship within 30 days. Complex turnkey lines involving multi-stage processes require 8–12 weeks for fabrication, testing, and documentation preparation.

Can suppliers integrate automation systems with existing factory infrastructure?

Yes, many suppliers support legacy equipment integration using standardized communication protocols (Modbus, Profibus, EtherCAT). Provide detailed specifications on current machinery, power requirements, and network architecture to enable seamless interoperability planning.

Do suppliers offer after-sales technical support?

Support policies vary. Leading suppliers typically provide remote troubleshooting, operator training, and basic spare parts packages. Extended warranties and on-site service may be available at additional cost. Clarify SLAs for response and resolution times before contract finalization.

How to initiate a customization request?

Submit comprehensive technical requirements including production throughput (units/hour), part dimensions, material types, process sequence, environmental conditions, and safety standards. Reputable suppliers will respond with conceptual layouts, component selections, and timeline estimates within 3–5 business days.