Custom Pcb Design Services

Top sponsor listing

Top sponsor listing

1/25

1/25

1/26

1/26

1/60

1/60

1/51

1/51

1/61

1/61

1/3

1/3

1/37

1/37

1/9

1/9

1/15

1/15

1/34

1/34

1/24

1/24

About custom pcb design services

Where to Find Custom PCB Design Services Suppliers?

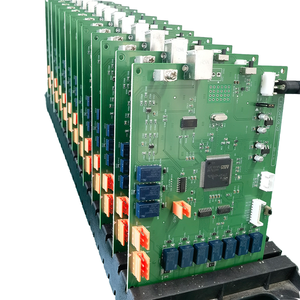

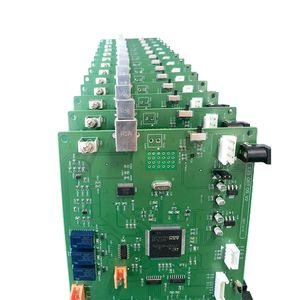

China remains the central hub for custom PCB design and manufacturing, with Shenzhen and Wuhan emerging as key industrial clusters due to concentrated electronics ecosystems. Shenzhen, a global leader in rapid prototyping and low-to-mid volume production, hosts vertically integrated facilities offering end-to-end services—from schematic capture and Gerber generation to component sourcing, assembly, and testing. The region’s proximity to semiconductor distributors, contract manufacturers, and logistics networks enables lead times as short as 5–7 days for prototype boards.

Wuhan-based suppliers specialize in high-density interconnect (HDI) and multilayer PCBs, often serving industrial automation, medical devices, and IoT sectors. These clusters benefit from localized supply chains that reduce material procurement time by 20–30% compared to non-specialized regions. Buyers gain access to scalable production lines capable of handling single-layer to 16-layer boards, with standard materials including FR4, ENIG, and flexible substrates. Typical advantages include MOQs as low as 1 piece, competitive pricing starting at $0.01 per unit for simple designs, and customization across board thickness, solder mask color, surface finish, and packaging.

How to Choose Custom PCB Design Services Suppliers?

Evaluate potential partners using these critical criteria:

Technical Capability & Compliance

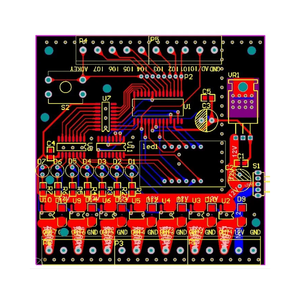

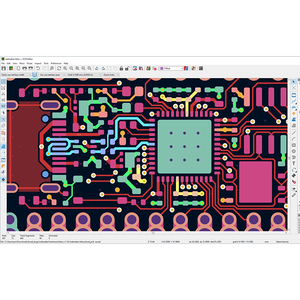

Confirm support for industry-standard design formats (Gerber, IPC-2581, ODB++) and compatibility with major EDA tools such as Altium Designer, KiCad, and Eagle. For export-bound electronics, ensure adherence to RoHS, REACH, and IPC-A-600 standards. Verify whether the supplier provides full traceability through BOM management, component authenticity checks, and post-assembly functional testing.

Production Infrastructure Assessment

Assess operational scale and process control through the following indicators:

- In-house capabilities covering PCB layout, fabrication, SMT assembly, and reflow soldering

- Support for specialized processes: impedance control, blind/buried vias, via-in-pad, and selective gold plating

- Turnkey service integration including component procurement, cloning, and firmware programming

Cross-reference on-time delivery performance (target ≥95%) with response time (ideally ≤2 hours) to gauge operational responsiveness.

Transaction Security & Quality Assurance

Prioritize suppliers with documented quality management systems and verifiable transaction histories. Use secure payment mechanisms that align financial release with milestone verification—especially for first-time engagements. Request sample builds to validate design accuracy, solder joint integrity, and final product functionality before scaling to mass production.

What Are the Best Custom PCB Design Services Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Scope |

|---|---|---|---|---|---|---|---|

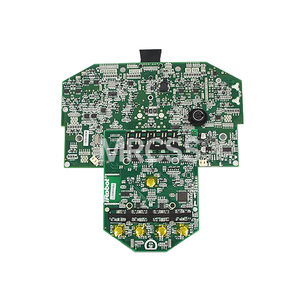

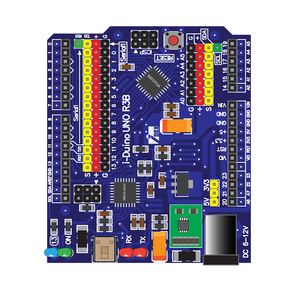

| Shenzhen Mrcss Electronic Co., Ltd. | Custom Manufacturer | Microcontrollers, FPGAs, Transistors, Resonators | 93% | <15% | ≤5h | US $490,000+ | Components, design, assembly |

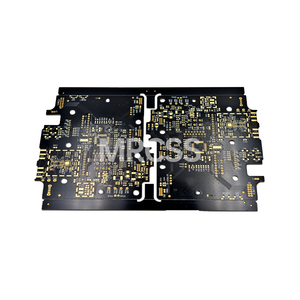

| Yuwei Electronic Technology (Wuhan) Co., Limited | Multispecialty Supplier | PCBA Development Boards, HDI, Multilayer PCB | 93% | 55% | ≤5h | US $300,000+ | Development kits, double-sided, multilayer |

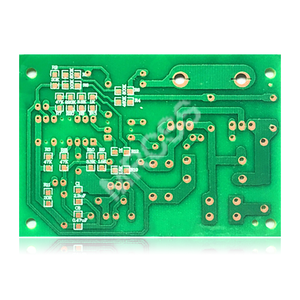

| Shenzhen Yachuanglian Technology CO.,Ltd. | Multispecialty Supplier | FR4, ENIG, FPC, HASL, solder mask, board thickness | 81% | 62% | ≤1h | US $270,000+ | Pcb size, material, color, logo, packaging |

| Shenzhen Aozite Technology Co., Ltd. | Multispecialty Supplier | Color, material, size, graphic, packaging | 100% | 40% | ≤2h | US $180,000+ | Surface finish, label, logo, flexible options |

| Kinglisheng(Shenzhen) Electronic & Technology Co., Limited | Custom Manufacturer | Flexible PCB, cloning, component sourcing, gerber files | 96% | 47% | ≤1h | US $330,000+ | FPC, RGB design, material, assembly |

Performance Analysis

Shenzhen Aozite leads in reliability with a perfect 100% on-time delivery rate, making it ideal for time-sensitive projects. Shenzhen Yachuanglian and Kinglisheng stand out for customization depth, supporting complex specifications like flexible circuits, ENIG finishes, and branded labeling. High reorder rates (62% and 47%, respectively) indicate strong customer satisfaction among these providers. While Shenzhen Mrcss reports the highest online revenue, its low reorder rate suggests room for improvement in client retention. For rapid engagement, prioritize suppliers with sub-2-hour response times—particularly critical during iterative design phases.

FAQs

How to verify a custom PCB design service provider's reliability?

Cross-check technical claims with available product listings and supported file formats. Review order history metrics such as on-time delivery and response speed. Request references or sample outputs to assess design precision and documentation quality.

What is the typical lead time for custom PCB prototypes?

Standard 2-layer PCB prototypes are typically delivered within 5–7 working days. Complex multilayer or HDI boards may require 10–15 days depending on stack-up complexity and surface finish requirements. Add 3–5 days if components need sourcing or assembly.

Do suppliers support full turnkey solutions?

Yes, many suppliers offer complete turnkey services including BOM analysis, component procurement, PCB fabrication, SMT/THT assembly, testing, and packaging. Confirm inventory availability for critical ICs and whether counterfeit avoidance policies are enforced.

What is the minimum order quantity for custom designs?

MOQs typically start at 1 piece for prototype runs, with volume discounts applying at 10, 100, and 1,000-unit thresholds. Some suppliers waive setup fees for repeat orders or long-term contracts.

Can I request design revisions after initial submission?

Most suppliers allow limited revisions during the pre-production phase at no additional cost. Changes affecting layer count, dimensions, or material specs may incur rework charges. Final Gerber approval is required before fabrication begins.