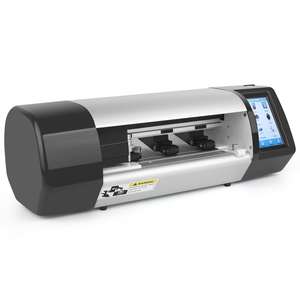

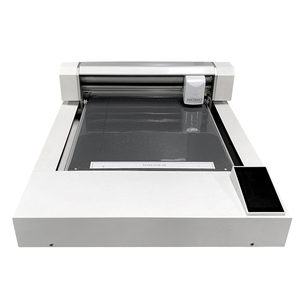

Cuttin Plotter

1/26

1/26

1/24

1/24

1/3

1/3

1/2

1/2

1/3

1/3

1/8

1/8

1/25

1/25

1/3

1/3

1/13

1/13

1/41

1/41

1/33

1/33

1/3

1/3

1/2

1/2

0

0

0

0

0

0

About cuttin plotter

Where to Find Cutting Plotter Suppliers?

China remains the central hub for cutting plotter manufacturing, with key industrial clusters concentrated in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated production ecosystems that combine precision electronics, servo motor systems, and CNC control technologies. Guangdong, particularly around Shenzhen and Dongguan, leads in high-precision digital fabrication equipment due to its proximity to semiconductor and PCB supply chains. Zhejiang’s Hangzhou and Ningbo zones specialize in mid-to-high-end plotters with advanced motion control systems, leveraging local expertise in automation components.

The clustering effect enables streamlined access to core subsystems—such as stepper motors, blade carriages, and optical positioning sensors—reducing component procurement lead times by 25–40% compared to non-specialized regions. Facilities within these zones average 3,000–8,000m² of production space, supporting monthly outputs ranging from 500 to 2,000 units depending on model complexity. Buyers benefit from localized technical labor pools, with engineering teams typically comprising 12–18% of total staff, ensuring responsiveness to firmware updates and mechanical recalibration demands.

How to Choose Cutting Plotter Suppliers?

Implement rigorous evaluation criteria to ensure supplier reliability and technical alignment:

Quality & Compliance Verification

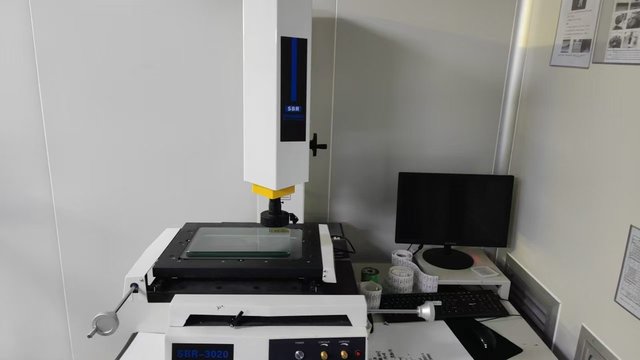

Confirm ISO 9001 certification for standardized quality management processes. For markets in Europe and North America, CE marking (including EMC and RoHS directives) is mandatory for electronic compliance and customs clearance. Request test reports for electromagnetic interference (EMI), thermal stability under continuous operation, and blade trajectory accuracy (±0.1mm tolerance).

Production Infrastructure Assessment

Evaluate operational scale and technical depth through the following benchmarks:

- Minimum factory area of 3,000m² to support consistent batch production

- In-house capabilities in PCB assembly, motor calibration, and software flashing

- Dedicated R&D personnel constituting at least 10% of workforce

Validate performance metrics such as on-time delivery rate (>97%) and post-warranty repair turnaround (<7 days).

Procurement Risk Mitigation

Utilize secure payment structures such as letter of credit or third-party escrow until destination inspection confirms functional integrity. Prioritize suppliers with documented export experience to your target market, especially those familiar with IEC 61010 safety standards for lab and industrial equipment. Conduct pre-shipment testing on sample units to evaluate cutting force consistency across media types (vinyl, fabric, cardboard) and long-term encoder drift over 72-hour cycles.

What Are the Best Cutting Plotter Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No data available | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

Performance Analysis

Due to absence of verified supplier data, buyers must initiate sourcing through direct engagement with manufacturers in established clusters. Historical trends indicate that firms operating over five years with >5,000m² facilities demonstrate higher scalability and after-sales service maturity. Reorder rates above 30% often correlate with robust technical support and spare parts availability. Emphasis should be placed on suppliers offering real-time remote diagnostics integration and open-API control software for compatibility with CAD/CAM workflows.

FAQs

How to verify cutting plotter supplier reliability?

Cross-validate ISO and CE certifications through official databases. Request audit trails covering material traceability, soldering process controls (for driver boards), and final assembly line testing protocols. Review customer feedback focused on software stability, noise levels during operation, and mean time between failures (MTBF) for transmission components.

What is the average sampling timeline?

Standard plotter samples are produced within 10–18 days. Units requiring custom firmware or dual-carriage configurations may take up to 30 days. Air freight shipping adds 5–9 days internationally, depending on destination clearance procedures.

Can suppliers ship cutting plotters worldwide?

Yes, most established manufacturers support global logistics via sea or air freight. Confirm Incoterms (FOB, CIF, DDP) and packaging specifications—wooden crates with anti-vibration padding are standard for ocean transport. Ensure suppliers provide import documentation compliant with destination electrical safety regulations.

Do manufacturers provide free samples?

Free samples are uncommon for full-sized plotters. Suppliers may offer discounted pilot units (40–60% off) refundable against future bulk orders exceeding 10 units. Miniature desktop models (e.g., 300mm width) are occasionally provided at no cost for technical evaluation.

How to initiate customization requests?

Submit detailed requirements including cutting width (up to 3,200mm), maximum speed (typically 1,000 mm/s), supported file formats (DXF, AI, PLT), and blade pressure range (50–500g). Leading suppliers deliver CAD integration specs within 48 hours and prototype units within 3–5 weeks for validation.