Denso 6 Axis Robot

About denso 6 axis robot

Where to Find DENSO 6-Axis Robot Suppliers?

China remains a central hub for industrial robotics sourcing, with key supplier clusters concentrated in Shanghai, Jiangsu, Shandong, and Guangdong provinces. These regions host vertically integrated manufacturing ecosystems specializing in automation systems, collaborative robots (cobots), and articulated robotic arms compatible with DENSO’s 6-axis platforms. Shanghai and Jiangsu leverage proximity to advanced R&D centers and port infrastructure, enabling rapid prototyping and efficient global shipping. Shandong and Guangdong benefit from mature supply chains for servo motors, controllers, and end-effectors, reducing component lead times by up to 25% compared to non-specialized regions.

Suppliers in these zones typically operate multi-disciplinary facilities capable of CNC machining, welding, assembly, and system integration. This enables end-to-end production of robotic workcells, including customization for payload (ranging from 3kg to 9kg), reach, and application-specific tooling. Buyers can expect standard lead times of 30–45 days for pre-configured units and 60+ days for engineered solutions. The regional clustering also supports agile post-sales service, spare parts availability, and technical field support.

How to Choose DENSO 6-Axis Robot Suppliers?

Selecting reliable suppliers requires structured evaluation across three core dimensions:

Technical Capability & Compliance

Verify that suppliers demonstrate compatibility with DENSO robot architectures through documented integration experience. While formal OEM authorization may be limited, credible partners provide evidence of interoperability via control interface specifications, communication protocols (e.g., TCP/IP, Modbus), and application testing logs. ISO 9001 certification is recommended as a baseline quality management indicator. For EU and North American markets, ensure compliance with CE or ANSI/RIA safety standards for collaborative operations.

Production and Customization Capacity

Assess supplier infrastructure using the following benchmarks:

- Minimum factory area exceeding 3,000m² to support robotic cell assembly

- In-house engineering teams capable of modifying gripper types, arm spans, and programming interfaces

- Proven ability to customize color, labeling, packaging, and functional modules (e.g., vision systems, force sensors)

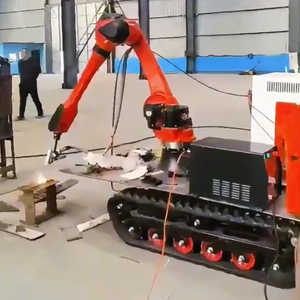

- CNC, laser cutting, and welding capabilities for structural components

Cross-reference online revenue data and reorder rates (>20%) as indicators of market validation and scalability.

Transaction Reliability & Risk Mitigation

Prioritize suppliers with verifiable performance metrics: on-time delivery ≥94%, response time ≤7 hours, and minimum two-year operational history. Utilize secure payment mechanisms such as escrow services until site acceptance testing is completed. Request product videos, configuration drawings, and software demonstration packages before order placement. Conduct virtual or on-site audits to validate production lines and quality assurance procedures.

What Are the Best DENSO 6-Axis Robot Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Xiangjing (Shanghai) Mechanical and Electrical Tech Co., Ltd. | Shanghai, CN | US $50,000+ | 100% | ≤7h | 20% | Color, material, size, payload, logo, packaging, gripper | 1 set | $16,000–39,000 |

| Shandong Jiaxin Machinery Equipment Co., Ltd. | Shandong, CN | US $1,200,000+ | 94% | ≤2h | 26% | Color, size, logo, arms, material, function, 3D scanner | 1–2 sets | $3,500–8,580 |

| Guangdong Hwashi Technology Inc. | Guangdong, CN | US $760,000+ | 100% | ≤4h | 33% | Color, material, size, logo, packaging, graphic | 1 set | $10,000–20,000 |

| Shenzhen Muma Automation Technology Co., Ltd. | Guangdong, CN | US $300,000+ | 100% | ≤2h | 39% | Automation, color, material, robotic arm, gripper | 1 piece | $5,500–14,500 |

| Jiangsu Greatway Electrical Co., Ltd. | Jiangsu, CN | Not disclosed | 100% | ≤5h | Not available | Limited (based on listed products) | 1 set | $3,000–30,000 |

Performance Analysis

Shandong Jiaxin and Guangdong Hwashi exhibit strong customer retention (26–33% reorder rates) and high-volume transaction histories, indicating consistent product performance and service reliability. Shenzhen Muma stands out with a 39% reorder rate and sub-2-hour response time, reflecting operational agility and buyer trust. Xiangjing (Shanghai) offers the highest price-tier solutions ($39k max), suggesting specialization in high-payload or precision applications. Notably, multiple suppliers offer entry-level 6-axis robotic arms below $5,000, catering to SMEs and educational institutions requiring cost-effective automation. Buyers seeking full application integration should prioritize suppliers listing grippers, scanners, or polishing tools as customizable options.

FAQs

How to verify DENSO 6-axis robot supplier credibility?

Request documentation of past integrations involving DENSO controllers or compatible software environments. Validate certifications through issuing bodies and review transaction records via trade assurance programs. Analyze customer feedback focusing on system stability, repeatability accuracy, and technical support responsiveness.

What is the typical MOQ and lead time?

Standard MOQ is 1 set or piece, with select suppliers requiring 2 sets for discounted pricing. Lead times range from 15–30 days for off-the-shelf models and 45–60 days for customized configurations, depending on complexity and component availability.

Can suppliers customize robotic arms for specific applications?

Yes, most suppliers support modifications including gripper type, arm length, paint color, branding, and functional attachments (e.g., welding heads, polishing spindles). High-end providers offer integration with vision systems and IoT-enabled monitoring platforms upon request.

Do suppliers provide samples or trial units?

Sample policies vary. Some manufacturers offer demo units at reduced cost, particularly for orders exceeding five units. Trial periods are uncommon; instead, suppliers often provide simulation software or video demonstrations of operation.

Are DENSO-compatible robots export-ready?

Yes, established suppliers manage international logistics under FOB or CIF terms. Confirm voltage compatibility (220V/380V), control language options (English interface), and compliance with destination-country electrical and safety regulations prior to shipment.