Design Of Production System

CN

CN

CN

CN

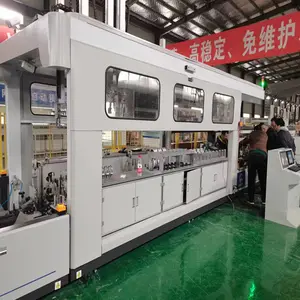

About design of production system

Where to Find Production System Design Suppliers?

China remains a central hub for production system design and turnkey manufacturing solutions, with specialized industrial clusters in Jiangsu, Henan, and Guangdong provinces. These regions host integrated supply ecosystems that support full-cycle development—from conceptual engineering to automated line deployment. Nanjing and Shanghai serve as key centers for high-complexity industrial automation systems, particularly in electric vehicle and glass manufacturing sectors, leveraging proximity to R&D institutions and port logistics networks.

Henan and Guangdong have emerged as leading bases for modular production systems in agriculture and metal processing, benefiting from established component supplier networks and cost-efficient fabrication capabilities. The concentration of engineering talent and vertically integrated workshops enables rapid prototyping and scalable deployment. Buyers can expect lead times of 45–90 days depending on system complexity, with localized supply chains reducing overall project costs by 20–35% compared to Western alternatives. Customization flexibility is a hallmark, supported by digital design tools and agile manufacturing frameworks.

How to Choose Production System Design Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Engineering & Customization Capability

Verify suppliers’ ability to deliver end-to-end system integration, including process flow design, automation controls (e.g., DCS/PLC), material handling, and environmental management. Prioritize firms offering 3D modeling, simulation testing, and compliance with industry-specific standards (e.g., ISO 14644 for cleanrooms). Confirm customization scope for parameters such as throughput capacity, footprint constraints, energy efficiency, and integration with existing infrastructure.

Production Infrastructure Assessment

Evaluate core competencies through the following criteria:

- Proven experience in turnkey projects (minimum 3–5 completed installations)

- In-house engineering teams capable of full-system design and commissioning

- Integration of control systems (e.g., SCADA, IoT monitoring) and automation components

- Facility size and equipment portfolio indicating scalability

Cross-reference delivery performance (target ≥90% on-time rate) and response time (≤6 hours) as indicators of operational reliability.

Quality Assurance & Transaction Security

Demand documented quality management systems, preferably ISO 9001-certified processes. For export markets, ensure compatibility with CE, UL, or other regional safety and electrical standards where applicable. Utilize secure payment mechanisms such as escrow services, especially for high-value contracts exceeding $100,000. Request site visitation rights or video audits to validate factory conditions and project execution capability prior to order placement.

What Are the Best Production System Design Suppliers?

| Company Name | Specialization | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Min. Order Value |

|---|---|---|---|---|---|---|---|

| Nanjing Energy Intelligent Co., Ltd. | Electric Vehicle & General Production Lines | Safety Driving Monitoring Systems, Metal Processing Lines | 100% | - | ≤6h | Design, configuration, packaging | $300,000 |

| Zhengzhou Satrise Industry Co., Ltd. | Mushroom Farming Systems | Growing Equipment, Climate Control, Sterilization Units | 88% | 20% | ≤6h | Size, color, material, labeling, insulation, lighting | $40,000 |

| Guangdong Chuangzhi Intelligent Equipment Co., Ltd. | Metal Coating & Assembly Automation | Powder Coating Lines, Conveyor Systems, Dust-Free Workshops | 100% | <15% | ≤1h | System layout, automation level, component selection | $98,500 |

| Henan Htx Group Co., Ltd. | Flexible Stone & Cladding Production | Artificial Stone, Split Facade, Decoration Material Lines | 90% | 25% | ≤3h | Color, size, logo, packaging, material formulation | $26,500 |

| Shanghai Pony Engineering Co., Ltd. | Flat Glass Manufacturing Systems | Float Glass Lines, Kiln Solutions, DCS-Controlled Plants | 100% | - | ≤3h | Process design, control integration, energy optimization | $1,000 |

Performance Analysis

Suppliers like Nanjing Energy Intelligent and Guangdong Chuangzhi demonstrate exceptional delivery consistency (100% on-time), critical for large-scale industrial rollouts. Zhengzhou Satrise offers niche expertise in agricultural biotech systems with comprehensive climate and sanitation integration, reflected in its higher reorder rate (20%) and broad customization range. Henan Htx Group provides mid-tier investment options with strong adaptability in building materials production, while Shanghai Pony stands out for ultra-low entry barriers ($1,000 minimum) and proven EPC (Engineering, Procurement, Construction) delivery models in glass manufacturing. Rapid response times (≤1h) at Guangdong Chuangzhi indicate high operational readiness, beneficial for urgent project scoping.

FAQs

How to verify production system design supplier credibility?

Review documented project portfolios, client references, and certification records (e.g., ISO, CE). Conduct virtual or physical factory audits to assess engineering capacity and quality control workflows. Analyze historical delivery data and customer feedback focusing on post-installation support and system uptime.

What is the typical lead time for custom production systems?

Lead times range from 60 to 120 days, depending on technical complexity and component sourcing. Standardized systems (e.g., mushroom farms, coating lines) typically ship within 60–90 days. Highly engineered solutions (e.g., float glass lines) may require 4–6 months for full commissioning and testing.

Can suppliers handle international installation and commissioning?

Yes, many suppliers offer overseas technical support and turnkey implementation services. Confirm availability of English-speaking engineers, site preparation guidelines, and warranty terms covering remote diagnostics and spare parts supply. Additional fees usually apply for on-site supervision.

Do production system suppliers provide process validation reports?

Reputable suppliers deliver detailed documentation including P&ID diagrams, control logic schematics, safety interlocks, and performance test results under load conditions. Request FAT (Factory Acceptance Test) reports before shipment to confirm functional compliance.

What are common customization parameters in production system design?

Key variables include hourly output capacity, automation level (manual, semi-auto, fully automatic), power requirements (voltage/frequency), spatial layout, material compatibility, and integration with ERP/MES systems. Suppliers typically provide CAD layouts and operational simulations within 5–10 business days upon request.