Difference Between 2 Stroke Engine And 4 Stroke Engine

Top sponsor listing

Top sponsor listing

1/3

1/3

1/1

1/1

1/3

1/3

1/11

1/11

1/48

1/48

1/1

1/1

0

0

1/3

1/3

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

0

0

CN

CN

1/23

1/23

1/3

1/3

1/1

1/1

1/25

1/25

1/3

1/3

About difference between 2 stroke engine and 4 stroke engine

What Defines the Difference Between 2-Stroke and 4-Stroke Engines?

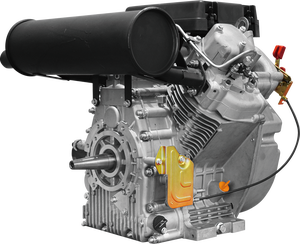

The fundamental difference between 2-stroke and 4-stroke engines lies in their operating cycles, combustion efficiency, and mechanical design. A 2-stroke engine completes one power cycle per crankshaft revolution, utilizing two piston strokes (intake/compression and power/exhaust) within a single rotation. This design enables higher power-to-weight ratios, making it ideal for lightweight applications such as chainsaws, leaf blowers, and small marine outboards. In contrast, a 4-stroke engine requires four piston strokes—intake, compression, power, and exhaust—over two crankshaft revolutions to complete a cycle. This results in improved fuel efficiency, lower emissions, and greater operational stability, commonly found in automotive, agricultural, and industrial machinery.

From a manufacturing perspective, 2-stroke engines feature simplified construction with fewer moving parts—absence of valve trains reduces assembly complexity and production costs by approximately 15–25% compared to 4-stroke equivalents. However, this simplicity comes at the expense of lubrication integration; 2-strokes rely on oil-fuel mixing, increasing particulate emissions and limiting compliance with stringent environmental regulations such as EPA Tier 4 and EU Stage V. Conversely, 4-stroke engines incorporate dedicated lubrication systems and overhead camshaft or pushrod valve actuation, enabling precise combustion control and longer service intervals but requiring more sophisticated machining processes including CNC-milled cylinder heads and precision-ground crankshafts.

Manufacturing Capabilities and Production Infrastructure

Global production of internal combustion engines is concentrated in industrial hubs across China, India, Germany, and the United States, with distinct specialization patterns. Chinese manufacturers dominate low-to-mid displacement engine output, particularly in Zhejiang, Jiangsu, and Guangdong provinces, where vertically integrated supply chains support mass production of both 2-stroke and 4-stroke units. These clusters house die-casting facilities for aluminum housings, automated bore-honing lines for cylinder liners, and robotic assembly cells capable of producing up to 50,000 units monthly per facility.

Typical materials used include high-silicon aluminum alloys for engine blocks (reducing weight by 30% vs. cast iron), nitrided steel crankshafts for wear resistance, and composite reed valves in high-performance 2-strokes. Processing techniques emphasize dimensional accuracy: 4-stroke cylinder heads undergo multi-axis CNC machining to ensure valve seat concentricity within ±0.02mm tolerance, while 2-stroke transfer ports are optimized through flow bench testing to enhance scavenging efficiency. Monthly production capacity among mid-tier suppliers ranges from 10,000 to 30,000 units, scalable based on automation level and component sourcing strategy.

Quality Standards and Certification Requirements

Compliance with international standards is critical for market access. Reputable engine manufacturers maintain ISO 9001-certified quality management systems, with additional requirements varying by region and application. For export to North America and Europe, CE marking and EPA certification are mandatory for off-road engines, covering noise, vibration, and exhaust emissions under ISO 8178 and ISO 1585 test procedures. 4-stroke engines typically meet Euro 5 or equivalent emission norms through catalytic converters and electronic fuel injection (EFI), whereas most 2-stroke variants remain restricted to non-road use due to hydrocarbon emissions exceeding regulatory thresholds.

RoHS and REACH compliance must be verified for material safety, especially in consumer-grade equipment. Buyers should request full test reports—including dyno performance curves, thermal imaging of cooling fins, and crankcase pressure logs—to validate claimed specifications. Third-party inspection agencies such as SGS or TÜV recommend batch sampling according to ANSI/ASQ Z1.4 standards during final audit stages.

Procurement Specifications and Sourcing Considerations

Minimum Order Quantities (MOQs) vary significantly by engine type and customization level. Standard 2-stroke engines (e.g., 25cc–75cc air-cooled) typically require MOQs of 500–1,000 units, while 4-stroke models (e.g., 168F, 208F series) may start at 300 units due to higher per-unit cost and assembly time. Lead times average 30–45 days for containerized orders, extendable to 60 days for EFI-integrated or liquid-cooled configurations requiring calibration software integration.

Customization options include:

- Carburetor type (diaphragm vs. float bowl)

- Ignition system (CDI module tuning for RPM range)

- Mounting configuration (foot pattern, shaft length, keyway dimensions)

- Fuel delivery (pre-mix ratio adjustment for 2-strokes, oil pump inclusion)

Suppliers with in-house R&D teams (>10% technical staff ratio) can modify port timing or valve lift profiles to optimize torque curves for specific applications such as concrete saws or portable generators. Prototyping lead time averages 15–20 days, with validation samples subject to endurance testing over 100-hour duty cycles.

Supplier Evaluation and Risk Mitigation

To ensure reliability, conduct structured assessments prior to procurement:

Technical Compliance Verification

Confirm adherence to applicable emission standards and obtain certified test data. For 4-stroke engines, verify inclusion of oil alert systems and spark arrestors where required for forestry equipment.

Production Capability Audit

Evaluate supplier infrastructure using the following benchmarks:

- Minimum 3,000m² factory area with dedicated assembly and testing zones

- In-house dynamometer testing for every production batch

- CNC machining coverage exceeding 70% of critical components

- On-time delivery rate >95%, supported by documented logistics partnerships

Transaction Safeguards

Utilize secure payment structures such as irrevocable LC at sight or third-party escrow arrangements until post-arrival inspection confirms conformance. Require pre-shipment inspections (PSI) with defect classification per MIL-STD-105E. Retain sample sets from initial batches for comparative analysis in future orders.

FAQs

Can 2-stroke and 4-stroke engines be sourced interchangeably?

No. Application-specific design differences prevent direct substitution. 2-strokes offer higher power density but require frequent maintenance and emit more pollutants. 4-strokes provide better durability and emissions control but are heavier and costlier to produce. Substitution risks performance degradation and regulatory non-compliance.

What is the typical service life of each engine type?

Air-cooled 2-stroke engines last 250–500 operating hours under proper maintenance. 4-stroke engines generally achieve 1,500–3,000 hours due to superior lubrication and reduced thermal stress. Industrial-duty 4-strokes with cast iron sleeves exceed 5,000 hours with scheduled servicing.

Are electric-start variants available for both types?

Electric starting is standard on larger 4-stroke engines (≥200cc). On 2-strokes, it remains limited to specialized applications due to space constraints and added weight. Retrofit kits exist but compromise power-to-weight advantages.

How do fuel efficiency and operating costs compare?

4-stroke engines consume 20–40% less fuel than equivalent 2-strokes under continuous load. Oil consumption in pre-mix 2-strokes adds 15–25% to total fluid cost. Over a 1,000-hour period, 4-stroke ownership costs are typically 30% lower despite higher acquisition price.

Is customization feasible for niche applications?

Yes, provided minimum technical thresholds are met. Suppliers with engineering capacity can adapt ignition timing, gear reduction, or mounting interfaces. Submit detailed technical drawings and performance requirements early in negotiation to assess feasibility and tooling investment needs.