Difference Between Column And Row

About difference between column and row

Where to Find Suppliers for Column and Row-Related Industrial Equipment?

The global supply base for industrial products associated with "column" and "row" configurations—ranging from structural components to agricultural machinery and laboratory systems—is highly diversified, with key manufacturing clusters in China. Provinces such as Yunnan, Henan, and Guangdong host specialized suppliers that integrate material processing, fabrication, and assembly under one ecosystem. These regions benefit from mature logistics networks and access to raw materials like ABS plastic, borosilicate glass, and structural steel, enabling cost-efficient production and rapid export readiness.

Suppliers in these zones operate within vertically integrated frameworks, supporting both standardized and custom-engineered solutions. The proximity of component manufacturers, metallurgical facilities, and packaging units reduces lead times by 20–30% compared to decentralized production models. Buyers gain operational advantages including scalable order fulfillment (from single units to container-sized batches), consistent quality control, and faster prototyping cycles—critical for time-sensitive procurement in construction, agriculture, and scientific instrumentation sectors.

How to Choose Suppliers for Column and Row Configuration Products?

Effective supplier selection requires a structured evaluation based on technical capability, compliance, and transaction reliability:

Technical & Application Alignment

Verify that the supplier’s product portfolio matches the intended application—whether structural columns in building materials, row-based agricultural planters, or chromatography columns in lab environments. Request detailed specifications including dimensional tolerances, load capacity (for storage racks), or fluid dynamics data (for lab columns). For agricultural equipment, confirm compatibility with crop spacing standards (e.g., 2-row vs. 4-row maize planters).

Quality Assurance and Compliance

Prioritize suppliers demonstrating adherence to international quality benchmarks. While ISO 9001 certification is not explicitly stated in available data, on-time delivery rates above 98% and reorder rates exceeding 20% indicate robust internal quality management. For lab glassware, verify use of borosilicate glass (e.g., Type 3.3) resistant to thermal shock and chemical corrosion. In construction applications, ensure materials meet mechanical strength requirements for load-bearing performance.

Production and Customization Capacity

Assess scalability through facility metrics where available:

- Minimum order quantities (MOQs) vary significantly—from 1 piece for lab instruments to 50 sets for industrial shelving—indicating flexibility across buyer segments

- Customization capabilities include OEM branding, dimensional adjustments, and material substitutions (e.g., ABS plastic variants or steel grade upgrades)

- Suppliers with response times ≤3 hours demonstrate high operational responsiveness, critical for iterative design validation and urgent sourcing needs

Transaction Risk Mitigation

Leverage verifiable performance indicators: on-time delivery rates (three suppliers report ≥98%), reorder rates (up to 26%), and online revenue transparency (ranging from US $20,000 to over $150,000 annually). Utilize secure payment mechanisms and request pre-shipment inspections, especially for high-value orders such as multi-row harvesting machines priced up to $5,200 per set.

What Are the Leading Suppliers for Column and Row-Based Industrial Products?

| Company Name | Main Product Category | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Kunming Winhope Industry & Trade Co., Ltd. | Plastic Building Columns & Moulds | $135–300 | 1–2 pieces | 100% | ≤3h | 22% | US $110,000+ |

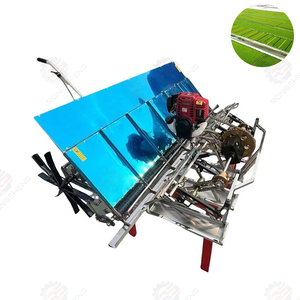

| Henan Sincerely Industrial Co., Ltd. | Agricultural Planting & Cultivation Machines | $450–680 | 1 set | 98% | ≤4h | <15% | US $150,000+ |

| AD RACKING STORAGE SYSTEMS PTE LTD | Steel Storage Racks (Column & Beam Systems) | $15–25 | 1–50 sets | - | ≤3h | - | - |

| Tianjin Chengsheng Glass Instrument Sales Co., Ltd. | Laboratory Chromatography Columns | $4.95–45.70 | 1 piece | 90% | ≤6h | 26% | US $20,000+ |

| Luohe Aijiesi Intelligent Equipment Co., Ltd. | Multi-Row Corn Harvesting & Forage Machines | $2,300–5,200 | 1 set | 100% | ≤2h | 18% | US $40,000+ |

Performance Analysis

Suppliers are segmented by application domain, allowing buyers to align vendor selection with technical requirements. Kunming Winhope and AD Racking specialize in structural column-and-beam systems, offering low MOQs ideal for pilot projects. Henan Sincerely and Luohe Aijiesi focus on agricultural row-sowing and harvesting technology, with the latter commanding premium pricing due to advanced multi-row automation. Tianjin Chengsheng stands out in precision lab equipment, achieving a 26% reorder rate—indicative of product reliability and customer satisfaction in scientific markets. Luohe Aijiesi leads in responsiveness (≤2h average reply) and perfect on-time delivery, making it a preferred partner for time-critical agri-machinery procurement.

FAQs

How to verify supplier credibility for column and row equipment?

Cross-reference delivery performance, response times, and reorder rates with third-party verification platforms. Request product certifications (e.g., material test reports, CE markings if applicable) and conduct virtual factory audits to assess production lines and quality control procedures.

What are typical lead times for these products?

Standard orders typically ship within 15–30 days. Customized items—such as OEM-branded chromatography columns or reinforced storage racks—may require 35–45 days depending on complexity and tooling requirements.

Can suppliers accommodate small trial orders?

Yes, multiple suppliers offer MOQs of 1 unit or set, particularly for high-value machinery and lab instruments. This enables risk mitigation through sample testing before large-scale procurement.

Do suppliers support customization?

Most suppliers listed provide customization options, including dimensional modifications, material upgrades, and branding. Confirm feasibility via technical drawings exchange and request prototypes when integrating into existing systems.

Are shipping and import logistics supported?

Established suppliers manage international freight via air or sea, offering FOB or CIF terms. Ensure compliance with destination regulations—especially for electrical or mechanized agricultural equipment requiring safety certifications.