Diffuser Bottle Luxury Distributor

Top sponsor listing

Top sponsor listing

1/3

1/3

1/25

1/25

1/3

1/3

1/22

1/22

1/11

1/11

1/3

1/3

1/3

1/3

0

0

1/20

1/20

0

0

1/21

1/21

1/30

1/30

1/1

1/1

1/3

1/3

About diffuser bottle luxury distributor

Where to Find Luxury Diffuser Bottle Distributors?

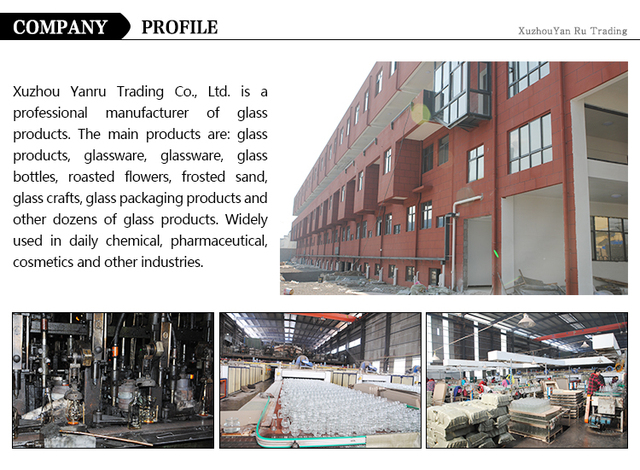

China leads global production of luxury diffuser bottles, with concentrated manufacturing hubs in Guangdong and Jiangsu provinces offering distinct competitive advantages. Guangdong, particularly the Pearl River Delta region, hosts over 70% of high-end glass packaging suppliers, leveraging advanced electroplating and silk-screen printing infrastructure for premium aesthetic finishes. Jiangsu’s Xuzhou cluster specializes in scalable production of reed diffuser systems, supported by integrated plastic and glass processing facilities that reduce component sourcing lead times by 25–30% compared to offshore alternatives.

These industrial zones feature vertically aligned supply chains—combining raw material processing, mold development, surface treatment, and final assembly—enabling rapid prototyping and volume scalability. Buyers benefit from localized ecosystems where cap manufacturers, labeling specialists, and logistics providers operate within compact geographic radii. Key benefits include reduced MOQs (as low as 2 pieces for sample orders), lead times averaging 15–25 days for customized batches, and extensive customization capabilities across materials, finishes, and packaging configurations.

How to Choose Luxury Diffuser Bottle Suppliers?

Implement these verification criteria when evaluating potential partners:

Production & Customization Capability

Assess technical flexibility in design execution. Leading suppliers offer comprehensive customization options including gradient glass effects, magnetic caps, frosted matte finishes, hot stamping, 3D rendering previews, and custom mold development. Confirm access to in-house tooling and engraving equipment to support unique bottle shapes, cap designs, and branding elements such as logo embossing or silk screening.

Material & Process Expertise

Evaluate proficiency in both glass and plastic packaging systems. Top-tier manufacturers utilize borosilicate or soda-lime glass for clarity and chemical resistance, paired with precision dropper assemblies or atomizing pumps. Verify process controls for critical stages like electroplating thickness consistency, crimping integrity, and leak testing. Suppliers should support dual-material lines (glass + plastic) to accommodate diverse fragrance diffusion requirements.

Quality Assurance & Transaction Metrics

Prioritize suppliers demonstrating verified performance through measurable KPIs:

- On-time delivery rate ≥97%

- Reorder rate exceeding 25% indicating customer retention

- Average response time ≤4 hours, ideally under 2 hours

- Documented quality inspection protocols pre-shipment

Cross-reference transaction data with observed online revenue (e.g., $190,000+ annual digital sales indicates established export capacity). For large-volume contracts, request evidence of internal QC teams and batch traceability systems.

What Are the Best Luxury Diffuser Bottle Distributors?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Verification Status |

|---|---|---|---|---|---|---|---|

| Guangdong Lianxin Glass Products Co., Ltd. | Glass Bottles, Jars, Plastic Tubes, Closures | Dropper caps, magnetic caps, engraving, gradient glass, silkscreen printing, refill valves, 3D rendering | 98% | 42% | ≤2h | US $1,400,000+ | - |

| Xuzhou Baide Glass Products Co., Ltd. | Glass Bottles, Plastic Jars, Bottles | Laser engraving, hand polishing, velvet boxes, stone caps, resin components, clamshell packaging, foil stamping | 100% | 28% | ≤2h | US $790,000+ | Custom Manufacturer |

| Xuzhou Didian International Trade Co., Ltd. | Glass Bottles, Candle Holders, Drinkware | Frosted eco-friendly finishes, custom logos, air freshener formats | 91% | 16% | ≤3h | US $370,000+ | - |

| Pingxiang Hongyao Glass Packaging Co., Ltd. | Glass Bottles, Plastic Jars, Tubes | Matte black finish, hot stamping, cap crimp design, decal application, matching box sets | 97% | 25% | ≤2h | US $190,000+ | Multispecialty Supplier |

| Xuzhou Paiwell International Trade Co., Ltd. | Glass Bottles, Plastic Bottles, Jars | Custom logo integration, square and round formats, essential oil and car freshener variants | 100% | 38% | ≤4h | US $150,000+ | - |

Performance Analysis

Guangdong Lianxin stands out with the highest reorder rate (42%) and strongest online revenue ($1.4M+), reflecting consistent buyer satisfaction and robust customization infrastructure. Xuzhou Baide and Paiwell achieve perfect on-time delivery records (100%), indicating strong operational discipline, while Baide offers the most sophisticated decorative options, including hand-polished and luxury-packaged configurations. Pingxiang Hongyao balances reliability (97% delivery) with mid-tier customization depth, making it suitable for branded retail lines. Xuzhou Didian, despite lower reorder metrics (16%), offers low MOQ sampling (2 pieces), ideal for startups and niche brands testing market fit.

FAQs

What is the typical MOQ for luxury diffuser bottles?

Minimum order quantities vary by supplier and complexity. Standard designs start at 100 units, while fully customized molds may require 1,000–5,000 units. Some suppliers offer as few as 2 pieces for initial sampling, enabling cost-effective design validation before scale-up.

How long does production and shipping take?

Lead times average 15–25 days for production, depending on customization scope. Add 7–14 days for international air freight or 25–40 days for sea shipment. Expedited processing (within 10 days) is available from select manufacturers for urgent orders.

Can suppliers provide free samples?

Most suppliers charge a nominal fee for samples, often refundable against future bulk orders. Fully customized prototypes may incur non-refundable setup costs covering mold adjustments or graphic design services.

What customization options are available?

Suppliers support extensive personalization: bottle shape (round, square, leaf-shaped), surface finish (frosted, matte, glossy), cap type (magnetic, wooden, zinc alloy), color (including gradient effects), and branding (logo engraving, silk screen, hot stamping). Packaging can be tailored with custom boxes, inserts, and label designs.

Do manufacturers comply with international quality standards?

While formal ISO certification is not explicitly stated in the dataset, top performers demonstrate compliance through high on-time delivery rates (>97%), structured QC processes, and transaction transparency. Buyers should request documentation for material safety (e.g., lead-free glass, RoHS-compliant coatings) and perform third-party inspections for regulated markets.