Digikey

0

0

1/2

1/2

1/2

1/2

1/2

1/2

1/1

1/1

1/3

1/3

0

0

0

0

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/8

1/8

1/3

1/3

0

0

1/3

1/3

0

0

1/1

1/1

0

0

About digikey

Where to Find Electronic Components Suppliers?

China remains a dominant force in the global electronic components supply chain, with key manufacturing and distribution hubs concentrated in Shenzhen, Hong Kong, and surrounding Guangdong regions. These areas host dense ecosystems of electronics distributors, OEMs, and component specialists, supported by mature logistics networks and proximity to semiconductor fabrication zones. The region's infrastructure enables rapid prototyping, just-in-time inventory fulfillment, and efficient export operations—critical for B2B buyers managing PCB assembly, product development, or after-sales service inventories.

Suppliers in this cluster benefit from integration with SMT line operators, IC programming services, and PCB manufacturers within a 50km radius, reducing lead times and enabling responsive reordering. Average delivery cycles range from 7–15 days for in-stock items, with many suppliers offering drop-shipping capabilities. Cost advantages stem from localized sourcing of substrates, packaging materials, and testing equipment, yielding 15–30% lower procurement costs compared to Western-distributed alternatives. Buyers also gain access to mixed-lot availability, including obsolete, active, and extended-shelf-life components.

How to Choose Electronic Components Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Component Authenticity & Traceability

Verify batch traceability, shelf-life status (e.g., 12-month shelf stock), and handling protocols for moisture-sensitive devices. Prioritize suppliers providing datasheets, original manufacturer references (e.g., Digikey cross-listings), and anti-static packaging compliance. For mission-critical applications, demand evidence of incoming quality inspection reports and counterfeit detection procedures (X-ray analysis, decapsulation).

Operational Performance Metrics

Assess supplier reliability using verifiable KPIs:

- On-time delivery rate ≥95%

- Average response time ≤4 hours

- Reorder rate >20% indicating customer retention

- Minimum online revenue threshold (e.g., US $30,000+) as proxy for transaction volume

Cross-reference these metrics with order history data where available. High reorder rates suggest consistent quality and fulfillment accuracy.

Transaction Security & Quality Assurance

Utilize platforms with escrow or trade assurance mechanisms to mitigate fraud risk. Require sample validation before bulk ordering—particularly for ICs, embedded controllers, and passives with tight tolerance requirements. Confirm ESD-safe handling practices and inspect packaging standards (sealed reels, humidity indicators) upon receipt. For long-term contracts, establish audit rights for warehouse conditions and inventory rotation policies.

What Are the Best Electronic Components Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Digikey Electronic Solutions (Hong Kong) Limited | Other Electronic Components, Drones Accessories, Optoelectronics, Terminal Blocks, Connectors | 86% | ≤2h | 21% | US $30,000+ | 1 piece | $0.54–19.35 |

| Shenzhen Fairtech Electronics Co.,LTD | Safety Products, Plastic Packaging, Safety Clothing, Gloves | 100% | ≤4h | <15% | US $10,000+ | 1 piece | $0.50–45.00 |

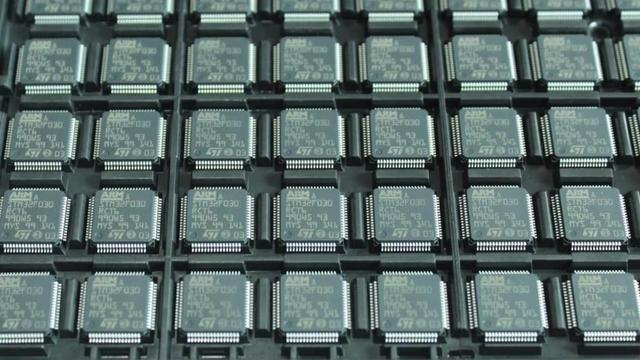

| Shenzhen Apex-Chip Technology Co., Ltd. | ICs, Development Boards, RF Modules, LCDs, PLCs | 100% | ≤13h | <15% | US $400+ | 1 piece | $0.55–1.79 |

| Shenzhen Jiayousheng Electronics Co., Ltd. | Embedded MCUs, Circuit Components | 87% | ≤3h | 33% | US $90,000+ | 1 piece | $0.55–1.30 |

| Vicko Electronics Technology Co., Limited | Microcontrollers, FPGAs, PMICs, EL Products, Potentiometers | 100% | ≤1h | 18% | US $50,000+ | 1 piece / 100 pieces | $0.55–16.57 |

Performance Analysis

Shenzhen Jiayousheng Electronics stands out with the highest reorder rate (33%) and substantial annual online revenue (US $90,000+), indicating strong buyer retention and market presence. Digikey Electronic Solutions (Hong Kong) offers broad product diversity and fast response times, though its 86% on-time delivery suggests room for improvement in logistics execution. Shenzhen Fairtech and Vicko Electronics achieve perfect on-time delivery records, with Vicko leading in responsiveness (≤1 hour). However, both report reorder rates below 20%, potentially signaling lower repeat business or niche customer bases. Price competitiveness is strongest among Shenzhen-based IC suppliers, with multiple vendors offering microcontrollers and embedded components under $1.30 per unit at single-piece MOQs.

FAQs

How to verify electronic components supplier reliability?

Validate authenticity through batch numbers, original manufacturer part cross-references, and shipping date tracking. Request test reports for functional verification, especially for programmed ICs or power management units. Analyze supplier communication patterns, documentation completeness, and adherence to ESD packaging standards.

What is the typical sampling timeline for electronic components?

In-stock samples ship within 1–3 business days. Lead times extend to 7–14 days for tested or programmed units. Air freight adds 3–7 days internationally. Expect delays for out-of-production or extended-shelf-life parts requiring warehouse retrieval.

Can suppliers provide small-batch or single-unit orders?

Yes, all listed suppliers support minimum order quantities of 1 piece, facilitating prototyping and repair workflows. Pricing scales favorably at 100+ units for select items such as connectors and passive arrays.

Do suppliers offer authorized distribution channels?

Some suppliers self-identify as authorized distributors. Buyers should request partnership documentation from original manufacturers to confirm authorization status, particularly for branded semiconductors and programmable logic devices.

How to manage risk when sourcing legacy or obsolete components?

Require aging reports, storage conditions (temperature/humidity logs), and burn-in testing results. Prefer suppliers with dedicated inventory rotation systems and those offering warranty-backed returns. Avoid suppliers without transparent sourcing disclosures or those unwilling to provide physical inspection access.