Digital Factory Formlabs

CN

CN

About digital factory formlabs

Where to Find Digital Factory Formlabs Suppliers?

China's digital printing and manufacturing technology sector is highly concentrated in coastal industrial hubs, particularly in Shanghai, Guangzhou, and Wuxi, where integrated supply chains support rapid development of digital factory solutions. These regions host specialized clusters focused on digital inkjet systems, UV printers, textile printing machinery, and photo minilab equipment—technologies closely aligned with automated digital production environments such as those pioneered by Formlabs in precision manufacturing.

The ecosystem benefits from vertically integrated components including printhead assembly, ink formulation, control software integration, and mechanical engineering. Proximity to raw material suppliers and electronics manufacturers reduces component lead times by up to 40% compared to offshore alternatives. Buyers gain access to mature infrastructure capable of delivering both standard and customized digital production units within 30–60 days, depending on complexity. Cost efficiencies are significant, with localized manufacturing enabling 25–35% lower pricing for comparable technical specifications versus Western suppliers.

How to Choose Digital Factory Formlabs Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Assessment

Prioritize suppliers offering verifiable expertise in digital inkjet systems, UV curing technology, or photoprocessing automation—core elements relevant to digital factory workflows. Confirm compatibility with resin-based, fabric, or paper substrates based on intended application. For integration into automated environments, evaluate software interfaces, machine-to-machine communication protocols, and calibration precision.

Production & Quality Verification

Assess supplier infrastructure using the following criteria:

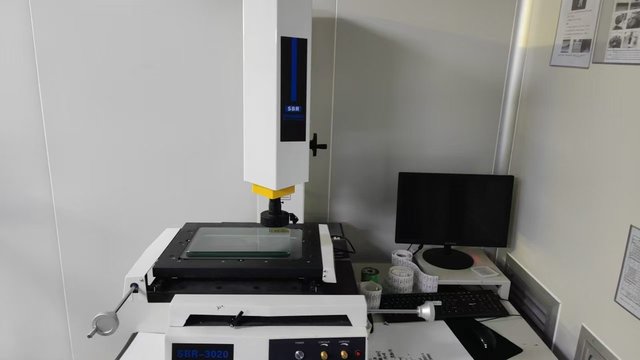

- Minimum 1,000m² production area for dedicated R&D and assembly lines

- In-house engineering teams specializing in digital printing controls or optical scanning systems

- Use of OEM-grade components (e.g., Epson, Ricoh, Konica Minolta printheads)

- Documented quality assurance processes, including pre-shipment testing and reconditioning logs for used equipment

Cross-reference online revenue metrics and reorder rates as indicators of market acceptance. A reorder rate above 25% suggests customer satisfaction with product reliability and after-sales service.

Transaction Security & Procurement Safeguards

Utilize secure payment mechanisms such as escrow services for high-value transactions, especially when purchasing reconditioned minilabs or large-format printers. Require detailed inspection reports, including test prints, system diagnostics, and video demonstrations prior to shipment. For bulk orders, insist on sample validation under real operating conditions before full deployment.

What Are the Best Digital Factory Formlabs Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| BASIC WORLD DALIAN LTD | Digital Minilabs, Photo Developing Systems | $5,500–$19,000 | 1 unit/set | 100% | ≤7h | <15% | $10,000+ | Limited |

| Shanghai Moreink Digital Technology Co., Ltd. | Digital Textile Printers, Ink Formulations | $2,000–$13,000 | 1 set/kg/barrel | 100% | ≤4h | 28% | $690,000+ | Extensive (color, material, design, logo, packaging) |

| Wuxi Kele Digital Technology Co., Ltd. | UV Inkjet Label Printers, Industrial Printers | $36,666–$69,888 | 1 piece | 100% | ≤1h | Not available | Not available | Moderate (resolution, condition, configuration) |

| Nanning Ida Electronic Tech Limited | Digital Minilabs, PCBs, Used Photolab Machines | $5,000–$20,600 | 1 piece/set | 75% | ≤7h | <15% | $10,000+ | Limited |

| Zhenfeng(guangzhou) Technology Co., Ltd. | Sublimation Printers, Home Textile Printing Systems | $2,000–$11,000 | 1–2 units/sets | 100% | ≤5h | 25% | $160,000+ | High (material, size, graphic, label, cotton type) |

Performance Analysis

Shanghai Moreink Digital Technology stands out for high-volume export performance and extensive customization capabilities, supported by a 28% reorder rate and sub-4-hour response time. Wuxi Kele targets premium industrial applications with high-ticket UV label printers, demonstrating strong technical focus despite limited public transaction data. Zhenfeng (Guangzhou) offers competitive pricing for textile-based digital printing systems with robust customization, appealing to buyers seeking flexible production setups.

BASIC WORLD DALIAN and Nanning Ida specialize in legacy digital minilab systems (Fuji Frontier, Noritsu QSS), catering to niche photo lab operators requiring reconditioned equipment. While BASIC WORLD maintains perfect on-time delivery, Nanning Ida’s 75% fulfillment rate indicates potential logistical constraints. All top-performing suppliers offer response times under 5 hours, underscoring the importance of real-time communication in procurement efficiency.

FAQs

How to verify digital factory equipment compatibility?

Request technical datasheets detailing interface standards (USB, Ethernet, SDI), software compatibility (Windows/Linux-based controllers), and substrate handling dimensions. For integration with existing automation, confirm API availability or PLC control support.

What is the typical lead time for digital printing machines?

Standard configurations ship within 15–30 days. Customized systems, especially wide-format textile or UV label printers, require 30–60 days depending on component sourcing and testing procedures. Reconditioned minilabs may have shorter lead times if stock is available.

Are samples available for digital printer verification?

Yes, most suppliers provide printed samples or remote test runs. Some charge nominal fees recoverable against future orders. Sample sets typically include output on multiple media types to assess color accuracy, resolution, and ink adhesion.

Do suppliers offer installation and training support?

Support varies. Larger suppliers often provide remote guidance via video or manuals. On-site installation may be available at additional cost. Confirm inclusion of user manuals, maintenance schedules, and firmware update policies before purchase.

Can digital factory systems be customized for specific materials?

Yes, especially in textile and UV printing segments. Suppliers like Shanghai Moreink and Zhenfeng offer adjustments for fabric width, ink viscosity, drying temperature, and print speed. Engineering modifications require formal technical consultation and may affect warranty terms.