Digital Print Machine For Fabric

CN

CN

Top sponsor listing

Top sponsor listing

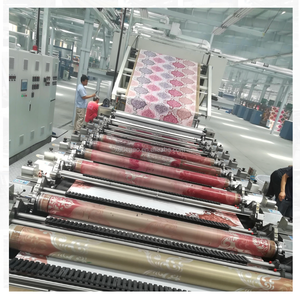

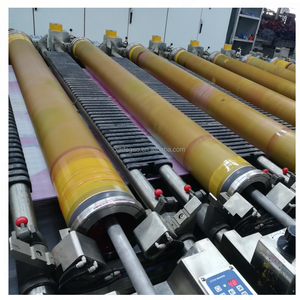

About digital print machine for fabric

Where to Find Digital Print Machine for Fabric Suppliers?

China remains the global epicenter for digital fabric printing machine manufacturing, with key industrial clusters concentrated in Guangdong, Henan, and Shaanxi provinces. These regions host vertically integrated supply chains encompassing printhead assembly, ink formulation, textile handling systems, and software development. Guangdong’s Shenzhen and Guangzhou hubs specialize in high-speed, precision digital textile printers, leveraging proximity to semiconductor and electronics suppliers for rapid component integration. Meanwhile, Henan's machinery-focused ecosystem supports cost-efficient production of roll-to-roll and flatbed models, particularly for DTG (Direct-to-Garment) and DTF (Direct-to-Film) technologies.

The clustering enables scalable production with lead times averaging 15–30 days for standard configurations. Suppliers benefit from localized access to Epson, Ricoh, and Kyocera-compatible printheads, UV/eco-solvent ink producers, and CNC-fabricated frames, reducing material procurement cycles by up to 40%. Buyers gain flexibility in MOQs—ranging from single units for entry-level A3 models to container-scale orders for industrial 180cm-wide machines—supported by modular design architectures that allow quick reconfiguration.

How to Choose Digital Print Machine for Fabric Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compatibility, operational reliability, and transaction security.

Technical Specifications & Compliance

Verify compliance with international electrical safety standards (CE, CCC) and electromagnetic compatibility directives. For export markets, confirm inclusion of multilingual RIP (Raster Image Processing) software and support for ICC color profiles. Assess print resolution (typically 720x720 dpi to 1440x1440 dpi), ink compatibility (aqueous, pigment, sublimation, or UV), and fabric adaptability (cotton, polyester, blends). Machines supporting white ink circulation systems and bidirectional printing offer enhanced versatility for textile decorators.

Production and Customization Capability

Evaluate supplier capacity based on:

- Minimum factory area exceeding 3,000m² indicating volume production infrastructure

- In-house engineering teams capable of firmware customization and mechanical modifications

- Offerings of OEM/ODM services including logo branding, voltage adaptation (110V/220V), and control panel localization

- Integration readiness with pre-treatment and curing systems (e.g., heat presses, dryers)

Cross-reference listed product ranges with actual output diversity—suppliers offering both DTG and DTF platforms demonstrate broader technical expertise.

Transaction and Quality Assurance

Prioritize suppliers with verifiable on-time delivery rates above 98% and response times under 2 hours. Confirm presence of automated cleaning functions, printhead protection mechanisms, and vacuum adsorption systems to minimize downtime. Utilize third-party inspection services for sample validation, testing print consistency, ink dispersion stability, and registration accuracy before bulk ordering. Escrow-based payment terms mitigate financial risk during initial engagements.

What Are the Best Digital Print Machine for Fabric Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Xian Degao Dye.& Pri. Auto Engineering Co., Ltd. | Textile Dyeing Machines (545), Inkjet Printers (58) | 100% | ≤6h | - | - | Color, material, size, logo, packaging, label, graphic |

| Guangzhou Xin Flying Digital Technology Co., Ltd. | Digital Fabric Printing Machines | 100% | ≤2h | 42% | US $1,100,000+ | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Chuangchengda Precision Manufacturing Co., Ltd. | DTF Printers, Mini Sticker Printers | 98% | ≤2h | 24% | US $570,000+ | Rotary printing, dual head, white ink, eco printing, garment printing, UV function, ink circulation, print resolution, material variety |

| Henan Zunsun Machinery Co., Ltd. | DTG Printers, Eco-Solvent Printers | 99% | ≤2h | 34% | US $750,000+ | Cotton/polyester printing, UV, sublimation, roll-to-roll, servo motor, vacuum adsorption, software language, auto-cleaning, dual heads, ink agitation |

| Zhengzhou New Century Digital Technology Co., Ltd. | A3 DTF Printers, Roll-to-Roll Models | 98% | ≤1h | <15% | US $3,000,000+ | Print width, tube length, guide rail, dual head, auto-cleaning, heating press, ICC profile, ink circulation, material size, consumables integration |

Performance Analysis

Guangzhou Xin Flying stands out with a 100% on-time delivery record and strong reorder rate (42%), indicating reliable fulfillment and customer satisfaction. Zhengzhou New Century reports the highest online revenue (US $3M+), reflecting extensive market reach, though its low reorder rate suggests room for improvement in post-sale engagement. Xian Degao offers deep specialization in textile processing equipment with over 500 dyeing machine listings, positioning it as a technically grounded supplier despite limited responsiveness (≤6h). Shenzhen Chuangchengda and Henan Zunsun provide balanced capabilities in DTF/DTG innovation with advanced features like bidirectional printing, white ink recirculation, and UV curing integration. All top-tier suppliers maintain response times under 2 hours, a critical factor for troubleshooting and technical coordination.

FAQs

What is the typical MOQ for digital print machines for fabric?

Most suppliers list MOQs at 1 set or piece, accommodating small businesses and startups. Bulk pricing typically applies from 5 units onward, with discounts negotiable based on total order value and long-term partnership potential.

What are common lead times after order confirmation?

Standard models ship within 10–20 days. Customized units requiring software adjustments, voltage changes, or mechanical modifications may require 25–35 days. Air freight delivers in 5–10 days; sea freight takes 20–40 days depending on destination port.

Do suppliers offer technical support and training?

Yes, most provide remote setup assistance via video call, user manuals in English, and basic operation guides. Advanced training on RIP software, maintenance protocols, and ink management is often available upon request, sometimes at additional cost.

Can these machines handle different fabric types?

Industrial-grade models support cotton, polyester, silk, denim, and synthetic blends. Pre-treatment coating is required for non-absorbent fabrics. Machines with adjustable platen height and vacuum suction systems offer better substrate adaptability.

What after-sales services should buyers expect?

Warranties range from 12 to 24 months, covering printhead motors, control boards, and mechanical components. Support includes spare parts supply, firmware updates, and troubleshooting. Some suppliers offer replacement units during repair periods for critical failures.